DOI:

https://doi.org/10.14483/22484728.7894Publicado:

2014-06-04Número:

Vol. 8 Núm. 1 (2014)Sección:

Visión de ContextoLaminated wood and chipboard flooring towards environmentally friendly alternatives

Palabras clave:

Chipboard flooring, wood flooring, laminated bamboo, regulations, environment. (es).Descargas

Referencias

http://www.sabelotodo.org/constru-ccion/tabloncillo.html, Nov. 20, 2013.

Y. Xiao, J. Mac. "Fire simulation test and analysis of laminated bamboo frame building" Construction and building materials, No. 34, 2012.

"El Bambú: la planta de los mil y un usos" “Nov 18, 2013 disponible en: http://www.youtube.com/watch?v=kC4cZlb1NHU

G. Medina. Normativa Europea de Parquet, Boletín de Información Técnica N° 221, 2003.

Convención Anual de la Federación Española de Pavimentos de Madera, Jun. 14, 2013 Girona, p 13-15,21.

FAUS, “Suelo Laminado & Friso”, Nov 10, 2013 disponible en: http://www.faus.es/blogsuelolaminadoyfriso/resistenciaa-la-humedad-del-suelo-laminado/

TermoFoam, Nov 10, 2013 disponible en: http://www.termofoam.com.mx/pdf/clasificacion_materiales.pdf.

"No son terror para la madera en construcción".In Revista M&M [On line]. Avaible: http://www.lopdf.net/preview/dxMRWmWEcf9GEB6PeJj5jpgLbIBxe1EPtuBTOSVz7w,/MATERIALES-Inflamabilidad-y-Combusti-243-n-M-amp-M.html?query=Diospyros-Ebenum

H. Li, Q. Zhang, D. Huang, A.J. Deeks. “Compressive performance of laminated bamboo. Composites Part B: Engineering”, volumen 54, pp. 320,–322-325, November 2013.

Pisos Bambú de Colombia, “El Bambú y sus propiedades”, Nov 20, 2013 disponible en: http://www.pisosbambudecolombia.

com/el-piso-de-bambu

Cómo citar

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Descargar cita

LAMINATED WOOD AND CHIPBOARD FLOORING TOWARDS ENVIRONMENTALLY FRIENDLY ALTERNATIVES

submitted date: November 2013

received date: Decembre 2013

accepted date: March 2014

Nayive Nieves Pimiento

B.Sc. In Mechanical engineering, Universidad Pontificia Bolivariana, Medellín (Colombia). Msc. In Environmental, Universidad Jorge Tadeo Lozano, Bogotá (Colombia). Current position. professor at Universidad Distrital Francisco José de Caldas, Bogotá (Colombia) . E-mail: nnievesp@udistrital.edu.co

Luis Ernesto Alférez Rivas

B.Sc. In Chemical engineering, Universidad América, Bogotá (Colombia) . Msc.In Environmental, Universidad Jorge Tadeo Lozano, Bogotá (Colombia). Current position: professor at Universidad Distrital Francisco José de Caldas, Bogotá (Colombia). E-mail: lealferezr@udistrital.edu.co

Néstor David Morales

B.Sc. In Industrial engineering, Universidad Distrital Francisco José de Caldas, Bogotá (Colombia). E-mail: nestor_4600@hotmail.com

Angie Stefani Caro Ballestas

B.Sc. In Industrial engineering, Universidad Distrital Francisco José de Caldas, Bogotá (Colombia). E-mail: stefis_3@hotmail.com

Abstract

The article presents a series of tests conducted over a sample of chipboard and wood flooring in order to compare some physical and chemical characteristics of these materials with other alternative raw materials that may replace wood. These alternative materials comply with the quality standards established by regulations on the conservation of the environment. Thus, a comparison is made between the results of tests on samples of chipboard and wood flooring and some of the research that has been done on the characteristics of laminated bamboo to be used as raw material in laminate flooring.

Key words

Chipboard flooring, wood flooring, laminated bamboo, regulations, environment.

1. Introduction

In recent years, with the fast economic and social growth worldwide, Bogotá (a capital city with more than seven million inhabitants) has also exhibited significant development. One of the most representative sectors showing such growth rates is construction, which has evolved rapidly since the beginning of this millennium; therefore, this sector receives more attention every day because it can either help or hinder the sustainability of society. Conventional construction is based on structures made of concrete, steal and Masonry, whose processes are high in resource consumption and in the degree of pollution caused. For these reasons, the search for new materials and technology that contributes to the development of this industry has been a challenge for society.

Wood is one of the most used natural organic materials and it has played a vital role in human history development, however it is common knowledge that these resources are limited due to their long growth cycle, thus attention has been paid to the global alert about the environmental problems. Therefore, there is an urgent need for finding new materials as alternatives or substitutes for wood, since wood dependence will cause severe ecological damage and climate changes, affecting the planet in the medium term. Although the construction industry has stopped, in large proportion, using wood as raw material in buildings, there is one activity that still uses wood largely, namely house and apartment remodeling. People still have a great pleasure to use wooden floors at home, since producers of such floors offer lifetime warranty and also a number of features in these products to encourage people to continue buying this type of products for their home, leaving aside the issues of environmental conservation and sustainable development. This is similar in the case of agglomerate homes, but their environmental impact is not as large as that of hardwood floors. This problem still exists, although the amount of wood used in these products is not the same as it used to be because they also are made with synthetic materials. Hardwood floors are expensive, delicate, responsive to changes in the environment, and also require frequent maintenance and air conditioning, and most importantly, require large amounts of high quality wood, which is commonly hard to reforest. Unfortunately, indiscriminate logging without any control is performed, [1]. The logging and illegal timber trade is a growing problem that threatens the survival of many species, particularly those with a high commercial value in national and international markets. This activity also threatens ecosystems and generates large-scale losses of flora and fauna. Indicative estimates cited in a recent World Bank1 paper point that, in Colombia, illegal logging accounts for approximately 42% of the total wood production. The manufacture of laminated flooring and chipboard floors has brought indiscriminate and continuous logging of trees, which endangers several species used as raw material in these processes. Proof of this is provided in Magazine M & M published in 2007, namely in an article entitled “First Red List of timber species threatened in Colombia”. This article shows that 441 timber species suffer from some degree of extinction; among them we found Sapan and Granadillo, species that today are used without any restriction as a source of raw material for the production of floors. Despite the establishment of Decree 1791 of 1996, Act 79 of 1986, Law 99 of 1993, the efforts to protect, conserve and restore the environment are joint efforts between the government, the private sector, the community and non-governmental organizations. Additionally, a large number of entities at the national level are responsible for environmental protection (Administrative Department of the Environment, for its acronym in Spanish, DAMA, Department of Environment SDA, etc.). It is evident, however, that there is a lack of control and concern by the authorities on this subject. It appears that new alternatives are required to greatly reduce this phenomenon of massive environmental destruction in the country, mainly caused by industrialization.

Recently, bamboo has received favorable attention as a potential alternative between existing conventional materials, because it is a source of resource worldwide, especially in countries like China and India. Bamboo is a green building material2 which has advantages of sustainability, it is environmentally friendly and has the ability to be reused or recycled, this species has a short growth cycle and user feedback, it can also be harvested in less than 4 years, [2]. In addition to high efficiency compared to other structural materials, Bamboo strength compared to weight ratios is much better than the common wood, cast iron, aluminum alloys and steel structures; therefore, its fair use in the industry can possibly help mitigate the demand for wood. The fact that bamboo is not fully utilized in modern structures is due in large part to the lack of approval based on the theory of mechanics, materials science and structural design. Bamboo is the world’s most versatile plant and is an excellent ecological and economic alternative; more than 1500 varieties of bamboo occupy almost 14 million hectares of land area. The spread of bamboo is currently generating huge profits. Given overpopulation and the consequent depletion of natural resources with irreversible effects on the environment, bamboo can be critical in finding solutions as well as in becoming an efficient producer of oxygen from the carbon dioxide. It is the fastest growing plant in the world, and is appropriately harvested annually. In addition to the renewable fibers that can be extracted with cellulose for paper making, bamboo is also an alternative fuel to non-renewable energy sources. This plant also supports conservation water sources due to the properties of its roots and the way it manages the extracted water to favor the needs of the soil or of its physiological activities. Bamboo only requires fifteen (15) minutes of annual maintenance, and there are several methods for its preservation, namely immersion in water with boron salts, smoked techniques, cutting at particular times and the formation of structures with alternative construction methods. Bamboo is a great timber line, colloquially known as the soles of the thousand and one uses, bamboo can be as strong as iron but much more flexible, and its cost is infinitely smaller. The best kinds of bamboo are used in the construction of bridges and houses, which turn out to provide excellent seismic capacities when compared to concrete, [3].

2. Hardwood and Chipboard floors Regulations

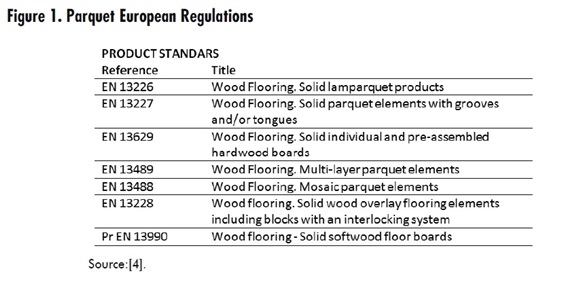

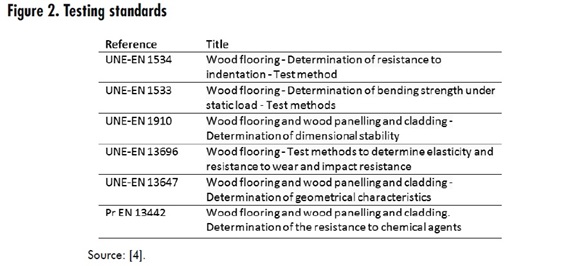

2.1 European standards [4]

- UNE-EN 1534 Determination of resistance to indentation - Test method. This recommendation describes a Brinell derivative method to determine the resistance to the “footprint” assay 3. This method consists in applying a load of 1000 N (100 Kgf) on the piece of timber, by using a steel ball, 10 mm in diameter. The standard includes measurement instructions on individual items and bundles, as well as the calculation of simple statistical values.

- UNE-EN 1533 Determination of bending strength under static load - Test methods. This recommendation describes two methods, one linear static load and a static point charge. In the first case the force is exerted through a steel cylinder in a horizontal position. In the second case, the cylinder is positioned vertically, i.e. the part that comes into contact with the pavement is circular-cylinder based. The standard includes a loading protocol to be followed for determining the modulus of elasticity.

- UNE-EN 1910 Determination of dimensional stability. This recommendation describes a test method for determining the behavior of wood flooring to climatic variations. The performance is evaluated by measuring the possible deformations of the elements.

- UNE-EN 13696 Test methods to determine elasticity and resistance to wear and impact resistance. This recommendation provides two methods, namely the TABER abrasion tester of sandpaper and sand blasting, and an evaluation form considering mass loss, thickness and abrasion to the bracket. Regarding the elasticity, it is measured on the tightness of a No-12 plate consisting of 7mm-diameter metal cones to achieve full insertion of the cones into the wood.

- UNE EN 13442. Determination of the resistance to chemical agents This recommendation describes a method for determining the resistance of the surface of a member of wooden flooring, against a series of common products in the home. The assay involves contacting the surface with these substances in small quantities and assesses damage on a scale of 1 to 5 according to their intensity 4. Figs. 1, 2.

2.2 Annual convention of the Spanish federation of wooden floors [5]

Standardization Determination of dimensional characteristics (UNE-EN 13647:2003 / UNE-EN 13329:2007+A1:2009), Fig. 3:

Dimensional stability tests • dimensional variations caused by variations in relative humidity (UNE-EN 1910:200 / UNE-EN 13329:2007+A1:2009), Fig. 4:

Tests of surface finish, Fig. 5:

- Impact Resistance (UNE-EN 13696:2008)

- Brinell Hardness (UNE-EN 1534:2000)

- Slip resistance (UNE-CEN/TS 15676:2008)

- Chemical resistance (UNE-EN 13442:2003)

Tests of mechanical properties such as flexural strength (UNE-EN 1533:2000), Fig. 6:

Standardization of timber products in Spain is through AENOR, particularly the AEN / CTN 56 committee - WOOD AND CORK

Performing normalization:

- Round wood, sawn wood and crushing

- Veneer and plywood; - conifer resin;

- Wood protection against biotic agents;

- SC1 Round wood Timber and forest products

- SC2 Wood Panels

- SC4 Protection of wood

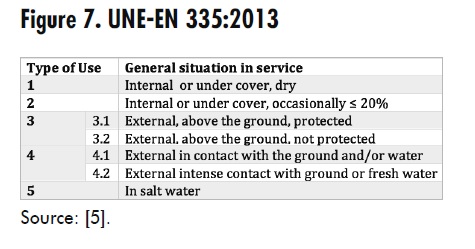

The species must have adequate natural durability for use in classes of use 3 or 4 (Standard UNE-EN 335:2013), Fig.7:

Otherwise a protective treatment should be applied. The water-soluble organic or protecting compounds are best suited for the use of non-durable wood to be used in classes 3 and 4 (deep impregnation autoclave)

Minimum dimensions and tolerances for exterior decking: Usually assumed to increase or decrease the size of sections, it is of 0.2% for each increase or of 1% for a decrease in the moisture content of the wood.

Minimum dimensions: Length: 40 cm

Thickness: 17 mm

Dimensional tolerances: Width: ± 1 mm from the nominal

Thickness: ± 0.5 mm from the nominal

Curl up 0.4% of the width of the piece

3. Experimental Results

In the process of analyzing the physical characteristics and behaviors of laminated and chipboard wood floor; moisture, fire, and chemical substance reaction testing procedures were followed considering the regulations to check if they satisfied the requirements.

3.1 Moisture Tests

3.1.1 Moisture test in laminated chipboard flooring

The test begins with three samples of agglomerate floors; 6mm, 7mm and 8mm, respectively; then the corresponding weights of each sample are taken to be subsequently introduced in a container with 1800 ml of water. The samples were subjected to the same characteristics of atmosphere and temperature measurements. The evolution of the samples was recorded every hour and the effects of water were thoroughly revised, Fig. 8.

This data-capturing process was performed with an interval of one hour between each test. Then we proceeded to take data every twelve hours, this analysis of the measurements of the samples was performed continuously for one hundred sixty eight hours (168), Fig. 9.

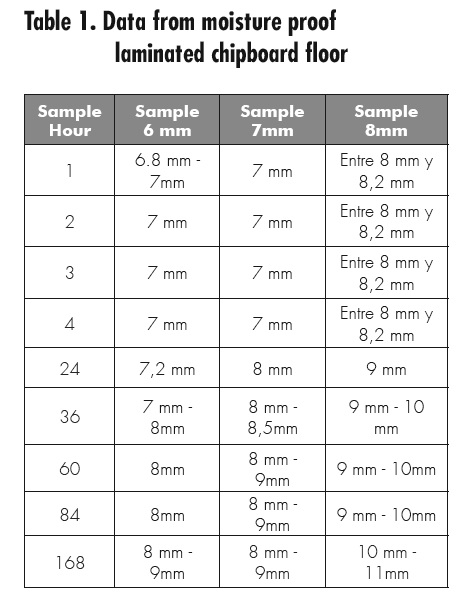

The results are shown in Table 1.

Test Conclusions: According to EN 13329, swelling is associated to a test in which a specimen of standard dimensions (laminate floor) is immersed in a water bath at 20 degrees Celsius for 24 hours. After this period it is dried and the thickness of the immersed part is determined and compared with the thickness of the non-immersed areas, which yields the swelling percentage of the soil tested. As stated in the rule, the maximum value of swelling soil allowed for domestic use is < 20% and for commercial use < 18%, i.e. the tests made on the samples of 6mm, 7mm and 8mm meet EN 13329, with < 20% in floor for domestic use. This analysis is carried out after 24 hours of observation over the behavior of the laminate floor, [6].

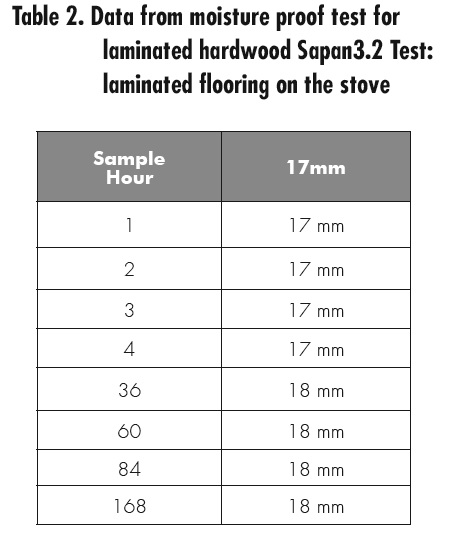

3.1.2 Moisture testing in laminated wooden floors (Sapan)

For this test, a 17mm-thick Sapan wooden foil was taken and placed in a vessel containing 1200 ml of water. In this container the foil was maintained for eight days at room temperature, and observations were made constantly to record the data obtained from the test, Fig. 10.

The result of this test revealed that after eight days of direct water exposure, the foil’s thickness increased by 1 mm, maintaining this constant measurement, Fig. 11.

The results are summarized in Table 2:

3.2.1 Test: agglomerate, laminated flooring on the stove

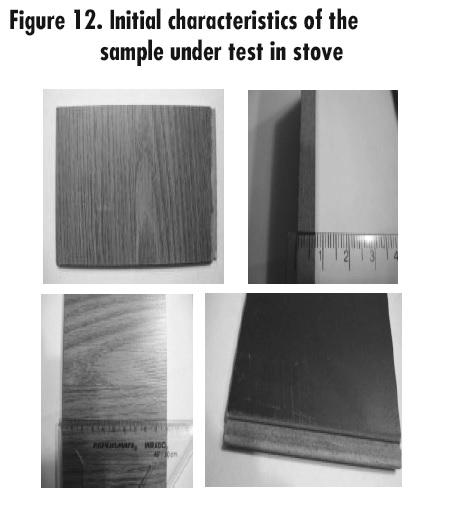

In this test a sample of 7mm laminated flooring was used by considering the initial characteristics, i.e. floor for domestic use with its corresponding layer overlay on top, and protective and insulating layer of moisture on its lower part, Fig. 12.

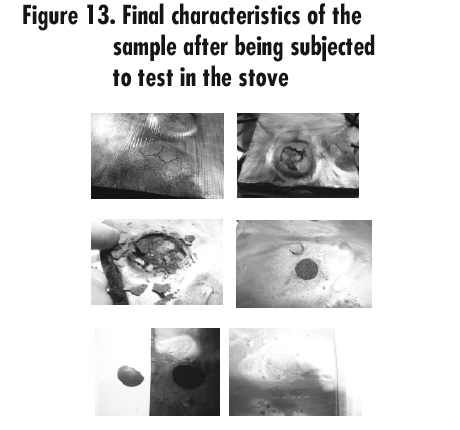

Then the sample is directly exposed to the flame of a stove, with temperatures ranging between 600 ° C and 700 ° C, and for a certain period of time, Fig. 13.

To see such effects on both the top and bottom of the sample, the following times were taken:

- Initially the bottom was left directly over the flame for 1:15 minutes

- Afterwards the top was left directly over the flame for 1:23 minutes

- The stove was turned off for about 2 minutes and the corresponding data of the effects caused by the fire were recorded.

- Again the top was placed directly over the flame for 2:15 minutes

- Finally the bottom was placed for 22 seconds and the effects of fire were finally analyzed on the samples.

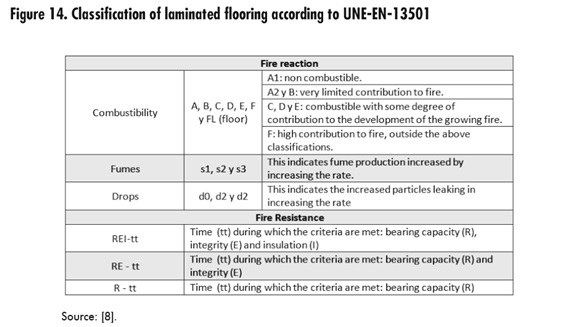

Test Conclusions: According to the UNE-EN 2002 -13 501, laminated flooring is noncombustible, and even if there is a fire source nearby, the floor will not last more than 20 seconds, bearing in mind that laminated floors are made with other synthetic materials, i.e. laminated floors are not solid wood, [7].

3.2.1 Test laminate flooring on the stove

Under the UNE-EN-135015 test fire resistance was performed on a 17mm-thick foil, where the effects of exposure to heat in a conventional stove at approximately 700 ° C were studied and analyzed. During the test, the piece was in contact with fire waiting for a combustion reaction, Figs. 14, 15.

Despite the contact, there was no increased combustion reaction, exposure and contact itself left obvious marks on the sheet as shown below (Figure 16):

In another study, industrial alcohol was applied on the surface of the foil in order to see the results and the effect on the piece of wood.

This test showed a decrease in the reaction time; however, a steady flame was not generated or maintained. The mark on the piece is a bit larger than that observed on the last test. Wood is not precisely a material liable to burn and promote burning after contact with a heat source of high temperature, in fact, in situations of fire, materials such as fabric, fibers, or existing coatings are those that most contribute to the development of fire. Actually, wood supports prolonged exposure times prior to burning, and much longer times before consumption, particularly if pretreated with flame retardants. In industrial applications, wooden floors are protected with a layer of polyurethane. Polyurethanes are a wide variety of polymers with total difference in composition, and their corresponding properties ensure protection against heat, scratches, chemical and water-based stain substances, since the surface is coated with a film of such hardness that, under natural conditions, wood is kept in its original state for tens of years without any alteration.

3.3 Test laminate flooring subjected to chemical agents

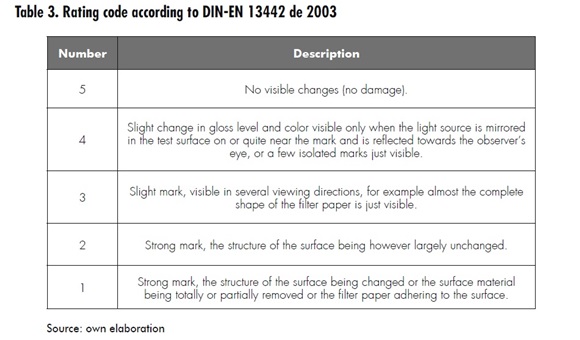

This test was performed based on standard “DIN-EN 13442 de 2003”6, which is a type of testing for chemical resistance together with a classification according to the test results (Table 3).

During the test, the Sapan wooden sheet was divided into three equal parts to ensure equal conditions and characteristics in order to contrast the changes that occur and the results obtained. Then a different chemical was applied on each of parts, namely Clorox, Thinner and Muriatic acid, respectively, Fig. 17.

After application of each substance on the surface, the following results were obtained: Fig 18

According to the applied standard, it follows that Clorox causes the most negative effect on the surface, and so it is classified in the range of 1-2, since there is a strong mark on the surface of the sheet.

4. Bamboo, a new alternative for sustainable development

4.1 Investigations [9]

Because bamboo is one of the most favorable alternatives as a substitute for wood laminate floors, the tests conducted are intended to ensure that its properties resemble those of other types of wood and even exceed the expectations in terms of production, maintenance and sustainability. The idea is to ensure bamboo’s entry into a new market as an efficient and durable material and as a conventional wood element.

Because of its novelty, standards specifying properties of bamboo are not yet available, nor acceptance standards to govern this new product. The following recommendations are therefore based on the experimental methodologies of existing studies.

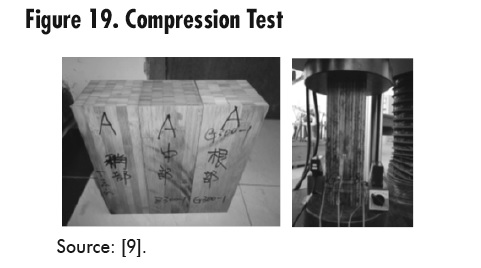

Compression test: During this test three sheets of bamboo were selected and developed, each from a different part of the cane, obtaining blocks of wood with the following dimensions: 100mm x 100mm x 300mm. The displacement along the axial axis was measured by two laser transducers SUD: Keyence IL-300. The test was conducted using an electro hydraulic universal microcomputer with a capacity of 2000 kN, Fig. 19.

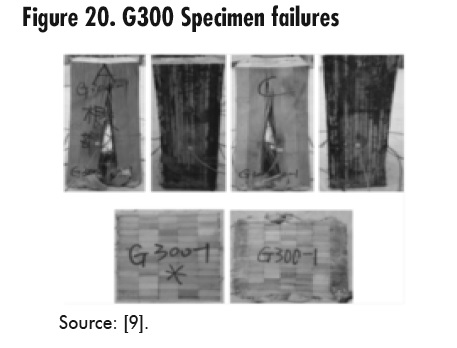

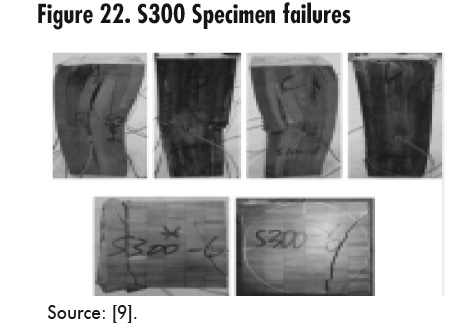

In the samples, various failure mechanisms are evident, Fig. 20.

The results showed an elastic behavior up to a load of 350kN, followed by a non-linear behavior up to 550 kN. The average modulus of elasticity was 8,641 MPa, Fig. 21.

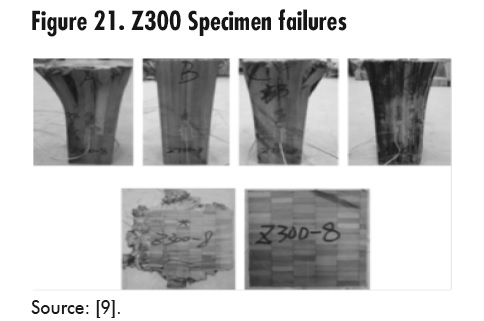

The second set of results showed an elastic behavior up to a load of 350kN, followed by a non-linear behavior up to 550 kN. The average modulus of elasticity was 10,628 MPa, Fig. 22.

Other results showed an elastic behavior up to a load of 350kN, followed by a non-linear behavior up to 550 kN, with an average modulus of elasticity of 9,322 MPa.

From these tests it can be deduced that the compressive strength is greater on the average. Depending on the height of the shaft, the variation of the resistance increases with the growth of the plant. Finally, based on the compression properties, the laminated bamboo can be regarded as a suitable material for engineering structures, [10].

Abrasion resistance,[10]: Over 4000 cycles are needed to remove the protective layer of the finish.

Chemical resistance, [10]:

- Acetic acid (5%)

- Ammonium hydroxide acetone (10%)

- Detergent toluene solution of ethyl alcohol (50%)

- Hydrochloric acid (10%)

- Place heavy turpentine (.025)

- Hydrogen peroxide (3%)

- Soap solution (1%)

- Sodium Hydroxide (1%)

Internal cohesion: 2107 Newton Moisture: 8- 10 % Density: 0.72 g / cm3

These tests demonstrate the stability and technical characteristics of bamboo flooring, recognizing it as a suitable material for building structures, [10].

5. Conclusions and future work

Environmental issues increase dramatically as time passes, and it seems that government policies have not been radical enough to solve such problems. This is a reason for different industrial sectors to find new ways to reduce the great impact of industrialization and generate alternatives, which has become a matter of social responsibility. Such is the case of decreasing the indiscriminate felling of trees. Thus, in order to alleviate the problem, this article presents tests on laminated flooring and agglomerate flooring in order to propose the use of more environmentally friendly materials.

The evidence presented herein was obtained under the corresponding laws, keeping in mind the reliability of the data and analyzes. From these results it can be concluded that wood offers a very good fire resistance due to its protective layer of coal. Furthermore, the evidence contributes to the numerous efforts of the industry to find methods that deal with obtaining timber of effective fire protection and many also facts that show how, even without the effect of flame retardants, this is one of the safest materials, so finding a replacement material will not be easy, however already shown several studies showing that other materials may withstand high temperatures without spreading fire, beside the continual development of increasingly efficient in the construction industry fireproof shields.

It is possible to meet all the requirements of standards, quality and sustainable development in the manufacturing process of laminate flooring and bamboo products derived from this raw material , the industry in recent years has been interested in this aspect , bamboo has become a resource that replaced complying with the various features of durability, beauty and quality to medium term timber as it is considered as one of the most popular renewable resources, is an herb that grows very fast and requires less land than trees have been used for different production processes in the last decades , in the same way have been conducted various tests on the timber generally have been made with different types of bamboo and show that meet the requirements in which focuses on the market of products made of wood but are guaranteed for life , they are currently endangered by logging , this study is an excellent starting point for help in great shape with responsibility in this process increasingly accelerated industrialization and globalization in our country.

References

[1]http://www.sabelotodo.org/constru-ccion/ tabloncillo.html, Nov. 20, 2013.

[2]Y. Xiao, J. Mac. "Fire simulation test and analysis of laminated bamboo frame building" Construction and building materials, No. 34, 2012.

[3]"El Bambú: la planta de los mil y un usos" “Nov 18, 2013 disponible en: http://www. youtube.com/watch?v=kC4cZlb1NHU

[4]G. Medina. Normativa Europea de Parquet, Boletín de Información Técnica N° 221, 2003.

[5]Convención Anual de la Federación Española de Pavimentos de Madera, Jun. 14, 2013 Girona, p 13-15,21.

[6]FAUS, “Suelo Laminado & Friso”, Nov 10, 2013 disponible en: http://www.faus. es/blogsuelolaminadoyfriso/resistenciaa- la-humedad-del-suelo-laminado/

[7]TermoFoam, Nov 10, 2013 disponible en: http://www.termofoam.com.mx/pdf/clasificacion_ materiales.pdf.

[8]"No son terror para la madera en construcción". In Revista M&M [On line]. Avaible: http://www.lopdf.net/preview/ dxMRWmWEcf9GEB6PeJj5jpgLbIBxe1EPtuBTOSVz7w,/ MATERIALES-Inflamabilidad- y-Combusti-243-n-M-amp- M.html?query=Diospyros-Ebenum

[9]H. Li, Q. Zhang, D. Huang, A.J. Deeks. “Compressive performance of laminated bamboo. Composites Part B: Engineering”, volumen 54, pp. 320,–322-325, November 2013.

[10] Pisos Bambú de Colombia, “El Bambú y sus propiedades”, Nov 20, 2013 disponible en: http://www.pisosbambudecolombia. com/el-piso-de-bambu

.png)

.jpg)