DOI:

https://doi.org/10.14483/2256201X.21457Publicado:

27-06-2024Número:

Vol. 27 Núm. 2 (2024): Julio-diciembreSección:

Artículos de investigación científica y tecnológicaEffect of Adding Oil Palm (Elaeis guineensis Jacq.) Mesocarp Fibers to Cement Composites

Efecto de la adición de fibras del mesocarpio de palma aceitera (Elaeis guineensis Jacq.) en compuestos de cemento

Palabras clave:

Fiber cement composite, lignocellulosic fiber, mesocarp fiber, oil palm, physical and mechanical properties (en).Palabras clave:

Compuesto de fibrocemento, fibra lignocelulósica, fibra de mesocarpio, palma aceitera, propiedades físico-mecánicas (es).Descargas

Referencias

Abdalla, J. A., Hawileh, R. A., Bahurudeen, A., Jyothsna, G., Sofi, A., Shanmugam, V., & Thomas, B. S. (2023). A comprehensive review on the use of natural fibers in cement/geopolymer concrete: A step towards sustainability. Case Studies in Construction Materials, 19, e02244. https://doi.org/10.1016/j.cscm.2023.e02244

Abdelmajeed Labib, W. (2019). Utilisation of date palm fibres in cement-based composites: A feasibility study. IOP Conference Series: Materials Science and Engineering, 596(1), 012028. https://doi.org/10.1088/1757-899X/596/1/012028

Adamu, M., Marouf, M. L., Ibrahim, Y. E., Ahmed, O. S., Alanazi, H., & Marouf, A. L. (2022). Modeling and optimization of the mechanical properties of date fiber reinforced concrete containing silica fume using response surface methodology. Case Studies in Construction Materials, 17, e01633. https://doi.org/10.1016/j.cscm.2022.e01633

Aguilar Gallegos, N., Arias Arias, N. A., & Santoyo Cortés, V. H. (2013). La palma de aceite (Elaeis guinensis Jacq.): Avances y retos en la gestión de la innovación (1st ed.). Universidad Autónoma Chapingo. https://repositorio.chapingo.edu.mx/items/6472388d-2443-4986-badd-c3cc3d7988d2

Alatshan, F., Altlomate, A. M., Mashiri, F., & Alamin, W. (2017). Effect of date palm fibers on the mechanical properties of concrete. International Journal of Sustainable Building Technology and Urban Development, 8(2), 68-80. https://doi.org/10.12972/susb.20170007

Alencar, M. A. S., Rambo, M. K. D., Botelho, G. L. G. T., Barros, P. M. M., Sergio, R. L., Borges, M. S., & Bertuol, D. (2023). Feasibility study of incorporation of bamboo plant fibers in cement matrices. Sustainable Chemistry for the Environment, 2, 100020. https://doi.org/10.1016/j.scenv.2023.100020

Ali, B., Hawreen, A., Ben Kahla, N., Talha Amir, M., Azab, M., & Raza, A. (2022). A critical review on the utilization of coir (coconut fiber) in cementitious materials. Construction and Building Materials, 351, 128957. https://doi.org/10.1016/j.conbuildmat.2022.128957

Ali-Boucetta, T., Ayat, A., Laifa, W., & Behim, M. (2021). Treatment of date palm fibres mesh: Influence on the rheological and mechanical properties of fibre-cement composites. Construction and Building Materials, 273, 121056. https://doi.org/10.1016/j.conbuildmat.2020.121056

Altez Basaldúa, A. G., Cárdenas Oscanoa, A. J., Araujo Flores, M., & Sulbarán Rangel, B. C. (2020). Efecto de pudrición por hongos en las propiedades físicas y mecánicas del compuesto bambú-polipropileno. Revista Mexicana de Ciencias Forestales, 11(62), 757. https://doi.org/10.29298/rmcf.v11i62.757

Arango-Pérez, S. A., Gonzales-Mora, H. E., Ponce-Álvarez, S. P., Gutarra-Espinoza, A. A., & Cárdenas-Oscanoa, A. J. (2024). Assessment of cellulose nanofibers from bolaina blanca wood obtained at three shaft heights. Maderas, Ciencia y Tecnología, 26, 1-30. https://doi.org/10.4067/S0718-221X2024005XXXXXX

Arao, Y., Fujiura, T., Itani, S., & Tanaka, T. (2015). Strength improvement in injection-molded jute-fiber-reinforced polylactide green-composites. Composites Part B: Engineering, 68, 200-206. https://doi.org/10.1016/j.compositesb.2014.08.032

Asyraf, M. R. M., Ishak, M. R., Syamsir, A., Nurazzi, N. M., Sabaruddin, F. A., Shazleen, S. S., Norrrahim, M. N. F., Rafidah, M., Ilyas, R. A., Rashid, M. Z. A., & Razman, M. R. (2022). Mechanical properties of oil palm fibre-reinforced polymer composites: A review. Journal of Materials Research and Technology, 17, 33-65. https://doi.org/10.1016/j.jmrt.2021.12.122

Awad, S., Ghaffar, S. H., Hamouda, T., Midani, M., Katsou, E., & Fan, M. (2022). Critical evaluation of date palm sheath fibre characteristics as a reinforcement for developing sustainable cementitious composites from waste materials. Biomass Conversion and Biorefinery, 14, 6887-6902. https://doi.org/10.1007/s13399-022-02759-9

Bajuri, F., Mazlan, N., & Ishak, M. R. (2017). Effect of silica nanoparticles in kenaf reinforced epoxy: Flexural and compressive properties. Pertanika Journal of Science and Technology, 25(3), 1029-1038. http://www.pertanika.upm.edu.my/pjst/browse/regular-issue?article=JST-S0280-2017

Banco Central de Reserva del Perú (BCRP) (2023). Producción agropecuaria por principales productos (miles de toneladas)—Agrícola—Agroexportación e Industrial—Palma Aceitera [dataset]. BCRP. https://estadisticas.bcrp.gob.pe/estadisticas/series/anuales/resultados/PM05090AA/html

Bellel, N., & Bellel, N. (2023). Sustainable heat insulation composites based on Portland cement reinforced with date palm fibers. Journal of Engineered Fibers and Fabrics, 18, 155892502311577. https://doi.org/10.1177/15589250231157718

Cárdenas-Oscanoa, A. J., Fuentes Talavera, F. J., Robledo Ortiz, J. R., Meza Contreras, J. C., & Gonzáles Cruz, R. (2020). Efecto del intemperismo y biodeterioro en compuestos plástico-madera (CPM) elaborados con borato de zinc. Revista Mexicana de Ciencias Forestales, 12(63), 801. https://doi.org/10.29298/rmcf.v12i63.801

Choi, Y. C. (2022). Hydration and internal curing properties of plant-based natural fiber-reinforced cement composites. Case Studies in Construction Materials, 17, e01690. https://doi.org/10.1016/j.cscm.2022.e01690

Cipra-Rodriguez, J. A., Gonzales Mora, H. E., & Cárdenas-Oscanoa, A. J. (2022). Characterization of MDF produced with bolaina (Guazuma crinita Mart.) wood residues from plantation. Madera y Bosques, 28(3), e2832433. https://doi.org/10.21829/myb.2022.2832433

Córdova Contreras, A. R., Cárdenas Oscanoa, A. J., & Gonzáles Mora, H. E. (2020). Caracterización física y mecánica de compuestos de Guazuma crinita Mart. A base de polipropileno virgen. Revista Mexicana de Ciencias Forestales, 11(57), 621. https://doi.org/10.29298/rmcf.v11i57.621

Coutts, R. S. P. (2005). A review of Australian research into natural fibre cement composites. Cement and Concrete Composites, 27(5), 518-526. https://doi.org/10.1016/j.cemconcomp.2004.09.003

De Souza Castoldi, R., Liebscher, M., Silva De Souza, L. M., Mechtcherine, V., Prioli Menezes, R., & De Andrade Silva, F. (2023). Effect of polymeric fiber coating on the mechanical performance, water absorption, and interfacial bond with cement-based matrices. Construction and Building Materials, 404, 133222. https://doi.org/10.1016/j.conbuildmat.2023.133222

Deutsches Institut fur Normung (DIN) (1965a). DIN 52361: 1965-04. Testing of wood chipcomposites – Determination of dimensions, raw density and moisture content. DIN.

Deutsches Institut fur Normung (DIN) (1965b). DIN 52364: 1965-04. Testing wood chipcomposite – Determination of moisture-related thickness variation. DIN.

Deutsches Institut fur Normung (DIN) (1965c). DIN 52365: 1965-04. Testing wood chipcomposite – Determination of tensile strength vertical to the chipboard plane. DIN.

Deutsches Institut fur Normung (DIN) (1982). DIN 53291: 1982-02. Testing of core composites – Compression test perpendicular to the surface layer plane.

Ezugwu, E. K., Calabria-Holley, J., & Paine, K. (2023). Physico-mechanical and morphological behavior of hydrothermally treated plant fibers in cementitious composites. Industrial Crops and Products, 200, 116832. https://doi.org/10.1016/j.indcrop.2023.116832

Feng, B., Liu, J., Lu, Z., Zhang, M., & Tan, X. (2023). Study on properties and durability of alkali activated rice straw fibers cement composites. Journal of Building Engineering, 63, 105515. https://doi.org/10.1016/j.jobe.2022.105515

Fernando, S., Gunasekara, C., Shahpasandi, A., Nguyen, K., Sofi, M., Setunge, S., Mendis, P., & Rahman, Md. T. (2023). Sustainable cement composite integrating waste cellulose fibre: A comprehensive review. Polymers, 15(3), 520. https://doi.org/10.3390/polym15030520

Goh, K. J., Wong, C. K., & Ng, P. H. C. (2017). Oil palm. In Elsevier (Eds.) Encyclopedia of Applied Plant Sciences (pp. 382-390). Elsevier. https://doi.org/10.1016/B978-0-12-394807-6.00176-3

Hamada, H. M., Shi, J., Al Jawahery, M. S., Majdi, A., Yousif, S. T., & Kaplan, G. (2023). Application of natural fibres in cement concrete: A critical review. Materials Today Communications, 35, 105833. https://doi.org/10.1016/j.mtcomm.2023.105833

Hasan, K. M. F., Horváth, P. G., & Alpár, T. (2022). Lignocellulosic fiber cement compatibility: A state of the art review. Journal of Natural Fibers, 19(13), 5409-5434. https://doi.org/10.1080/15440478.2021.1875380

Ishak, M. R., Leman, Z., Sapuan, S. M., Rahman, M. Z. A., & Anwar, U. M. K. (2013). Chemical composition and FT-IR spectra of sugar palm (Arenga pinnata) fibers obtained from different heights. Journal of Natural Fibers, 10(2), 83-97. https://doi.org/10.1080/15440478.2012.733517

Jamshaid, H., Mishra, R. K., Raza, A., Hussain, U., Rahman, Md. L., Nazari, S., Chandan, V., Muller, M., & Choteborsky, R. (2022). Natural cellulosic fiber reinforced concrete: Influence of fiber type and loading percentage on mechanical and water absorption performance. Materials, 15(3), 874. https://doi.org/10.3390/ma15030874

Jiang, D., Lv, S., Jiang, D., Xu, H., Kang, H., Song, X., & He, S. (2023). Effect of modification methods on water absorption and strength of wheat straw fiber and its cement-based composites. Journal of Building Engineering, 71, 106466. https://doi.org/10.1016/j.jobe.2023.106466

Junta Nacional de Palma Aceitera (JUNPALMA) (Ed.) (2022). Palma aceitera en el Perú: Reporte estadístico 2021. JUNPALMA. https://junpalmaperu.org/publicaciones/palma-aceitera-en-el-peru-2021/

Kareche, A., Agoudjil, B., Haba, B., & Boudenne, A. (2020). Study on the durability of new construction materials based on mortar reinforced with date palm fibers wastes. Waste and Biomass Valorization, 11(7), 3801-3809. https://doi.org/10.1007/s12649-019-00669-y

Khorami, M., & Ganjian, E. (2011). Comparing flexural behaviour of fibre–cement composites reinforced bagasse: Wheat and eucalyptus. Construction and Building Materials, 25(9), 3661-3667. https://doi.org/10.1016/j.conbuildmat.2011.03.052

Komuraiah, A., Kumar, N. S., & Prasad, B. D. (2014). Chemical composition of natural fibers and its influence on their mechanical properties. Mechanics of Composite Materials, 50(3), 359-376. https://doi.org/10.1007/s11029-014-9422-2

Kriker, A., Debicki, G., Bali, A., Khenfer, M. M., & Chabannet, M. (2005). Mechanical properties of date palm fibres and concrete reinforced with date palm fibres in hot-dry climate. Cement and Concrete Composites, 27(5), 554-564. https://doi.org/10.1016/j.cemconcomp.2004.09.015

La Rosa Salazar, M. A. (2021). Preocupaciones y cambios de política: ¿hacia la sostenibilidad de la palma aceitera en la Amazonía? Economía Agraria y Recursos Naturales, 21(1), 59. https://doi.org/10.7201/earn.2021.01.03

Lertwattanaruk, P., & Suntijitto, A. (2015). Properties of natural fiber cement materials containing coconut coir and oil palm fibers for residential building applications. Construction and Building Materials, 94, 664-669. https://doi.org/10.1016/j.conbuildmat.2015.07.154

Liu, K., Wen, Z., Zheng, Y., Xu, Y., Yu, J., Ye, J., Zhang, W., Zhong, W., Gao, X., & Liu, H. (2023). Microstructural feature of cellulose fibre in cement-based composites at different curing temperature. Journal of Building Engineering, 63, 105569. https://doi.org/10.1016/j.jobe.2022.105569

Momoh, E. O., & Osofero, A. I. (2020). Recent developments in the application of oil palm fibers in cement composites. Frontiers of Structural and Civil Engineering, 14(1), 94-108. https://doi.org/10.1007/s11709-019-0576-9

Neyra-Vasquez, J. Y., Panduro-Pisco, G., Díaz-Zúñiga, E. J., & Iannacone, J. (2022). Caracterización física y química: Biomasa residual de la palma (Elaeis guineensis Jacq.) en la Amazonia peruana. Agronomía Mesoamericana, 33(3), 48170. https://doi.org/10.15517/am.v33i3.48170

Pacheco-Torgal, F., & Jalali, S. (2011). Cementitious building materials reinforced with vegetable fibres: A review. Construction and Building Materials, 25(2), 575-581. https://doi.org/10.1016/j.conbuildmat.2010.07.024

Ramírez Contreras, N. E., Arévalo, A., & García Núñez, J. A. (2015). Inventario de la biomasa disponible en plantas de beneficio para aprovechamiento y caracterización fisicoquímica de la tusa en Colombia. Revista Palmas, 36(4), 41-54.

Raut, A. N., & Gomez, C. P. (2016). Thermal and mechanical performance of oil palm fiber reinforced mortar utilizing palm oil fly ash as a complementary binder. Construction and Building Materials, 126, 476-483. https://doi.org/10.1016/j.conbuildmat.2016.09.034

Ritchie, H., & Roser, M. (2021). Palm oil. Our World in Data. https://ourworldindata.org/palm-oil

RStudio Team (2023). RStudio: Integrated Development for R version 4.2.3 [Software]. RStudio Team. http://www.R-project.org

Savastano, H., Agopyan, V., Nolasco, A. M., & Pimentel, L. (1999). Plant fibre reinforced cement components for roofing. Construction and Building Materials, 13(8), 433-438. https://doi.org/10.1016/S0950-0618(99)00046-X

Savastano, H., Warden, P. G., & Coutts, R. S. P. (2005). Microstructure and mechanical properties of waste fibre–cement composites. Cement and Concrete Composites, 27(5), 583-592. https://doi.org/10.1016/j.cemconcomp.2004.09.009

Technical Association of the Pulp and Paper Industry (TAPPI) (1993). T. 211. Om-93. Ash in Wood, pulp, paper and papercomposite: Combustion at 525°C. TAPPI.

Technical Association of the Pulp and Paper Industry (TAPPI) (1997). T. 204. Cm-97. Solvent extractives of wood and pulp. TAPPI.

Technical Association of the Pulp and Paper Industry (TAPPI) (1998). T. 222. Om-98. Acid-insoluble lignin in wood and pulp. TAPPI.

Technical Association of the Pulp and Paper Industry (TAPPI). (1999). T. 207. Cm-99. Water solubility of wood and pulp. TAPPI.

Van Dam, J. (2016). Subproductos de la palma de aceite como materias primas de biomasa. Revista Palmas, 37(Special Issue), 149-156. https://publicaciones.fedepalma.org/index.php/palmas/article/view/11930

Vargas, E., & Zumbado, M. (2003). Composición de los subproductos de la industrialización de la palma africana utilizados en la alimentación animal en Costa Rica. Agronomía Costarricense, 27(1), 7-18.

Wahab, R., Sulaiman, M. S., Ghani, R. S. M., & Mokhtar, N. (2019). Properties of composite boards properties from Elaeis guineensis empty fruit bunch. Borneo Journal of Sciences and Technology, 1(1), 53-61. https://doi.org/10.35370/bjost.2019.1.1-11

Cómo citar

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Descargar cita

Recibido: 2 de noviembre de 2023; Aceptado: 10 de mayo de 2024

Abstract

The construction industry's ongoing pursuit of eco-friendly materials has led to extensive research into fiber cement composites (FCC), particularly those utilizing natural fibers such as oil palm (Elaeis guineensis Jacq.) mesocarp fiber (OPMF) from Peru. This study examined the physical, mechanical, and chemical effects of adding different proportions of OPMF (0, 3, 6, and 9%) in manufacturing FCCs. This addition resulted in reduced values regarding density, porosity, and modulus of rupture, as well as in increased moisture content and thickness reduction. The FCC containing 3% OPMF exhibited the most favorable performance thanks to its higher density and its lower water absorption and porosity when compared to the control board (0%-OPMF). Micro-images revealed minor microcracks and interfacial gaps, indicative of debonding, which compromises the properties of the FCC. Furthermore, an infrared spectrum analysis demonstrated an increase in hydroxyl group vibrations with an increased fiber proportion.

Keywords:

fiber cement composite, lignocellulosic fiber, mesocarp fiber, physical and mechanical properties.Resumen

La constante búsqueda de materiales ecológicos en la industria de la construcción ha llevado a una amplia investigación sobre los compuestos de fibrocemento (FCC), especialmente aquellos que utilizan fibras naturales como la fibra del mesocarpio de la palma de aceite (Elaeis guineensis Jacq.) (OPMF) de Perú. Este estudio examinó los efectos físicos, mecánicos y químicos de añadir diferentes proporciones de OPMF (0, 3, 6 y 9 %) en la fabricación de FCC. Esta adición resultó en valores reducidos en cuanto a densidad, porosidad y módulo de ruptura, así como un aumento en el contenido de humedad y una reducción del espesor. El FCC que contenía 3 % de OPMF mostró el rendimiento más favorable gracias a su mayor densidad y su menor absorción de agua y porosidad en comparación con la placa de control (0 % de OPMF). Las microimágenes obtenidas revelaron microfisuras menores y huecos interfaciales, indicativos de desprendimiento, lo que compromete las propiedades del FCC. Además, un análisis del espectro infrarrojo demostró un aumento en las vibraciones del grupo hidroxilo con el aumento en la proporción de fibra.

Palabras clave:

compuesto de fibrocemento, fibra lignocelulósica, fibra de mesocarpio, propiedades físico-mecánicas.INTRODUCTION

The oil palm (Elaeis guineensis Jacq.) is a highly productive and economically valuable crop, as it produces 10 times more than other oilseed crops. It produces 36% of the world’s oil, and its replantation cycle generally lasts 25-30 years. The oil palm is a tropical and perennial crop from the tropical rainforest regions of West Africa, and it has spread to every tropical region worldwide (Aguilar Gallegos et al., 2013; Goh et al., 2017; Wahab et al., 2019; Ritchie & Roser, 2021). Oil palm is one of the most important commodities in the world. It is a raw material in the food, chemical, and energy industries (Aguilar Gallegos et al., 2013; La Rosa Salazar, 2021). In 2019, the world produced 74.58 million tons of palm oil (Ritchie & Roser, 2021).

Peru has not been the exception to the rapid expansion of the oil palm, especially during the last 20 years (La Rosa Salazar, 2021). In 2022, the national production was 1.40 million tons, and it has shown an upward trend throughout this century (BCRP, 2023). Ucayali leads in oil palm fresh fruit bunch production, accounting for 19.23% of the national annual growth rate during the 2015-2021 period (JUNPALMA, 2022). This crop produces a huge amount of waste, which is not fully utilized and generally left to rot (Wahab et al., 2019; Neyra-Vasquez et al., 2022). However, this waste can be a raw material source, in the form of useful by-products, and its disposal can be economically, socially, and environmentally beneficial (Van Dam, 2016).

In the Peruvian Amazon, the palm oil extraction industry generates byproducts, including oil palm mesocarp fiber (Neyra-Vasquez et al., 2022), a bulky, lignocellulosic, and fibrous biomass that remains after the pressing of oil palm fruits (Van Dam, 2016). The yield of fresh fruit bunches to mesocarp fibers is 12-14% (Vargas & Zumbado, 2003; Ramírez Contreras et al., 2015). Mesocarp fiber is typically burned to produce energy (steam), although it can be alternatively used as soil fertilizer, for briquettes and pellets, as fast pyrolysis oil, as biocrude, in paper pulp, and in fiber composites (Ramírez Contreras et al., 2015; Van Dam, 2016).

The construction industry is responsible for the depletion of a significant number of non-renewable resources, and it emits millions of tons of carbon dioxide into the atmosphere (Pacheco-Torgal & Jalali, 2011). Decarbonizing this industry is an important step towards achieving the net-zero goals of many countries (Awad et al., 2022). In this context, the valorization of oil palm fibers in reinforcement cement composites could provide low-cost, sustainable construction and building materials from an underutilized resource (Awad et al., 2022). Furthermore, this approach could contribute to mitigating the environmental issues associated with waste disposal (Ali-Boucetta et al., 2021).

Plant fibers are collectively termed as lignocellulosic fibers due to their three major organic constituents (hemicellulose, cellulose, and lignin), and they provide a good mechanical performance of cement composites (Kriker et al., 2005; Abdelmajeed Labib, 2019; Momoh & Osofero, 2020; Hasan et al., 2022). In addition, natural fibers exhibit excellent thermal, acoustic, and electrical insulation properties. They are also biodegradable and can be burned and disposed of easily (Komuraiah et al., 2014). The key mechanical aspects for selecting suitable reinforcing fibers in cement composites are tensile strength and flexural properties. Oil palm fibers exhibit superior properties that enhance their potential for utilization as reinforcement in cement composites (Kriker et al., 2005; Abdelmajeed Labib, 2019). This research aimed to assess the physical and mechanical properties of fiber cement composites (FCC) with different proportions (0, 3, 6, and 9%) of oil palm mesocarp fibers (OPMF).

OBJECTIVES

The objectives of this study were to manufacture fiber cement composite materials with varying proportions of oil palm (Elaeis guineensis Jacq.) mesocarp fibers and to evaluate their physical and mechanical properties.

MATERIALS AND METHODS

Fiber characterization

Oil palm mesocarp residues, which contain fibers, were collected from a palm oil factory in Ucayali, Peru. The sieve size used to select the fibrous material with ambient moisture was N°8 (2830 µm). The selected material was immersed in water for 24 h to facilitate a mechanical pulping process at 10% consistency, using the 30 HP Bauer Disc Refiner with a disc diameter and a gap of 305 and 0.30 mm, respectively. The resulting fiber bundles are hereafter denoted as oil palm mesocarp fibers (OPMF).

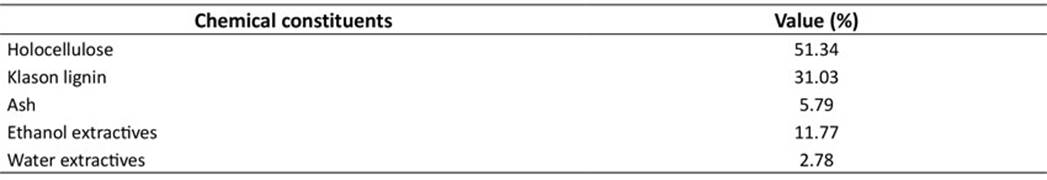

The chemical composition of the OPMF is shown in Table 1. The following parameters were determined: holocellulose (Jayme-Wise’s method), Klason lignin (T 222 om-98; TAPPI, 1998), ash (T 211 om-93; TAPPI, 1993), ethanol extractives (T 204 cm-97; TAPPI, 1997), and water extractives (T 207 cm-99; TAPPI, 1999). The values of chemical constituents were found to be consistent with those reported by Momoh and Osofero (2020) .

Table 1: Chemical composition of the OPMF

Furthermore, the physical dimensions of the OPMF were obtained using a digital USB microscope (model XA24) (Table 2). In comparison with the values reported by Asyraf et al. (2022) for oil palm empty fruit bunch, the diameter of the OPMF was similar, but they were shorter. Consequently, the aspect ratio was notably lower.

Table 2: Physical dimensions of the OPMF

Fiber cement composite manufacturing

Prior to FCC production, the OPMF were mineralized in a calcium chloride (Cl2Ca) solution at a concentration of 4% for a period of 15 min. Type I Portland cement paste (with a water/cement ratio of 0.4 w/w) was mixed with the OPMF at 0, 3, 6, and 9% by weight to produce the FCC. The resulting composite had a size of 350 x 350 x 10 mm and a final moisture content of 8.5% after three days of

Physical and mechanical characterization of the fiber cement composite

The following tests were conducted: moisture content (gravimetric method), density (DIN 52361; DIN, 1965a), water absorption (DIN 52364; DIN, 1965c), and porosity and volumetric swelling after 24 h of water immersion. Furthermore, the reduction in thickness was determined, following the application of a 39.23 MPa (400 Kg.cm-2) load (DIN 53291; DIN, 1982), as well as the modulus of rupture (MOR), at a speed of 6.35 mm/min (0.25 inch/min) (DIN 52362; DIN, 1965b).

Scanning electron microscopy (SEM)

The interplay between cement and fibers was examined, as well as the internal structure of the FCC, using a scanning electron microscope (SEM; Thermo Scientific, Quantum 250, USA) with 12.5 and 15 kV acceleration voltages and 34X and 140X magnification. The samples were previously prepared and coated with a diluted gold solution.

Fourier transform infrared spectroscopic analysis

A Bruker Alpha II (Germany) Fourier transform infrared (FTIR) spectrometer was employed to examine the molecular vibrations of samples while applying the attenuated total reflection (ATR) method. The spectra were recorded via successive scans in the wavenumber range between 400 and 4000 cm-1, with a resolution of 4 cm-1. The analyzed samples were the control board (0% OPMF), the FCC containing 3, 6, and 9% OPMF, and the OPMF.

Data analysis

An analysis of variance (ANOVA) was performed to identify disparities between the mean values of the FFCs’ physical and mechanical properties. Afterwards, the Tukey test was conducted to determine the significance in the mean values, as indicated by different letters in each of the presented graph. The R programming language version 4.2.3 (RStudio Team, 2023) was used for data analysis.

RESULTS

Physical properties

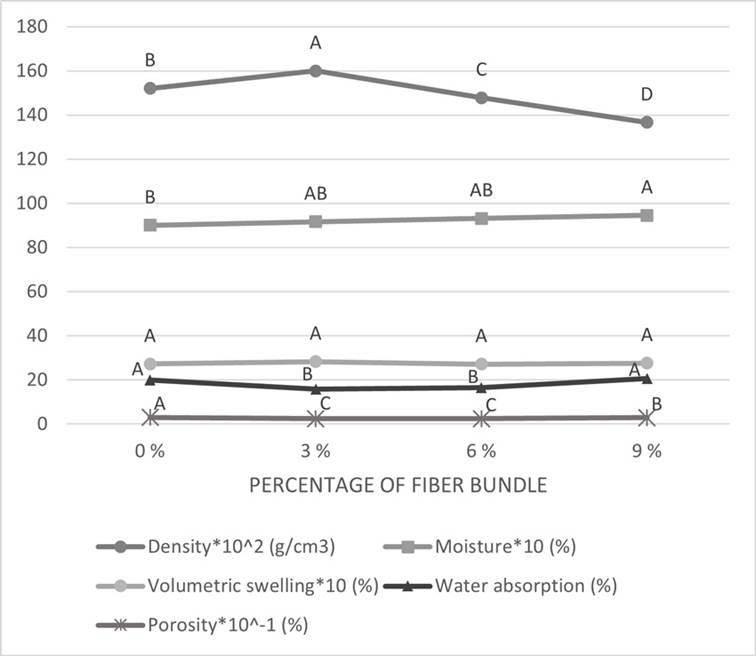

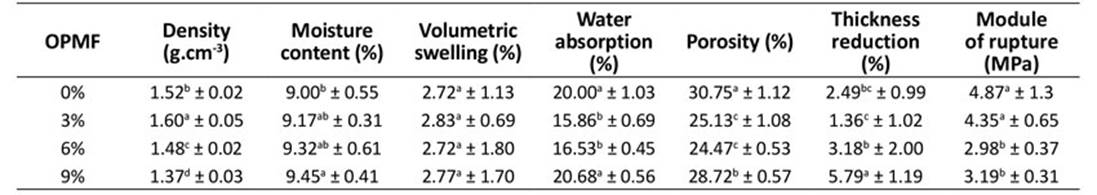

The physical properties tested were density, moisture content, volumetric swelling, water absorption, and porosity. The results are shown in Figure 1. The highest density was found in the FCC with 3% OPMF (1.60 ± 0.05 g.cm-3). The moisture content was not significantly different between FCCs, and the addition of 9% OPMF did not affect volumetric swelling or water absorption. The lowest porosity was found in the FCCs with 3% OPMF (25.13 ± 1.08%) and 6% OPMF (24.47 ± 0.52%).

Figure 1: Physical properties of FCCs with different OPMF proportions

Mechanical properties

The mechanical properties tested were thickness reduction and modulus of rupture (MOR). The results are shown in Figure 2.

Figure 2: Mechanical properties of FCCs with different OPMF proportions

The highest thickness reduction was found in the FCC with 9% OPMF (5.79 ± 1.18%). The MOR of the FCC with 3% OPMF (4.35 ± 0.65 MPa) was greater than those of the FCCs with 6% OPMF (2.98 ± 0.37 MPa) and 9% OPMF (3.19 ± 0.31 MPa), as well as similar to that of the control board (4.87 ± 1.30 MPa).

Scanning electron microscopy

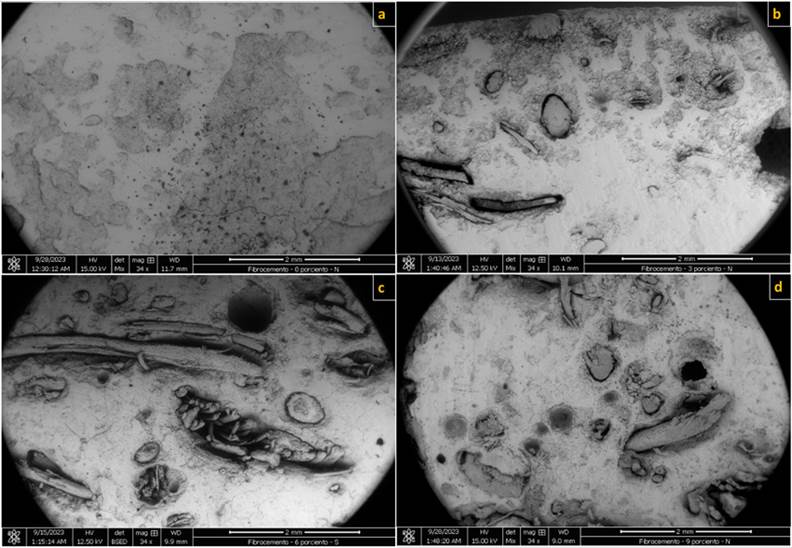

The OPMFs’ random distribution in the cementitious matrix is shown in Figure 3.

Figure 3: SEM images: a) control board (0% OPMF); b) FCC containing 3% OPMF; c) FCC containing 6% OPMF; d) FCC containing 9% OPMF

Individual fibers and bundles of fibers are easily distinguishable in Figures 3b, 3c, and 3d in comparison with the control board (Figure 3a).

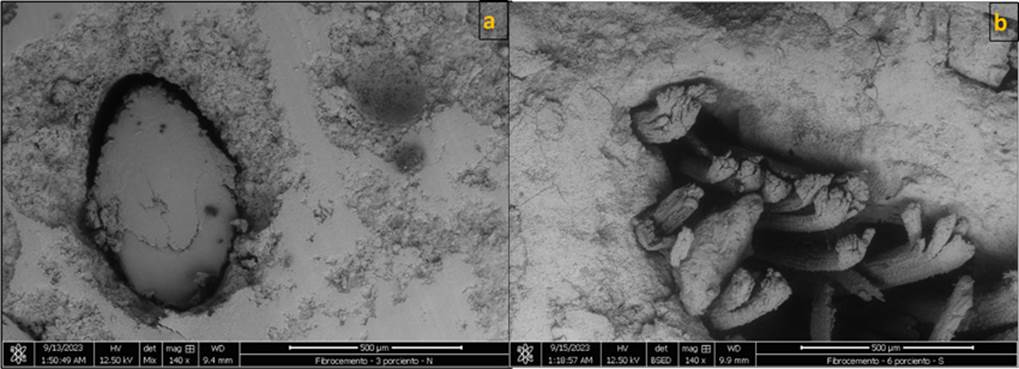

Figure 4: Internal structure of the FCC: a) an individual fiber and b) a bundle of fibers within the cementitious matrix

Figure 4 shows the internal structure of the FCC. A void distribution difference between an individual fiber (Figure 4a) and a bundle of fibers (Figure 4b) is observed.

Fourier-transform infrared spectroscopy

Figure 5 presents the FTIR spectra of the control board (0% OPMF), the FCCs containing 3, 6, and 9% OPMF, and the OPMF.

The FTIR graph shows vibrations in different band regions and similar patterns in the FTIR spectra.

Figure 5: FTIR spectra of the control board (0% OPMF), the FCCs containing 3, 6, and 9% OPMF, and the OPMF

DISCUSSION

Physical properties

The FCCs densities are reduced when the fiber proportion is increased. This indicates that adding higher OPMF contents tends to reduce the board density (Lertwattanaruk & Suntijitto, 2015; Adamu et al., 2022). The density of the composites is determined by the density and quantity of their components and their degree of compactness (voids/porosity) (Adamu et al., 2022). In this work, the control board (1.52 ± 0.02 g.cm-3) exhibited a lower density than the FCC with 3% OPMF (1.60 ± 0.05 g.cm-3). This is due to the presence of cavities, which is a characteristic of cementitious materials (Alencar et al., 2023), and to the increased number of voids resulting from the addition of fiber (Bellel & Bellel, 2023).

The similarity of the moisture contents in the FCCs can be explained by the fact that the fiber content was not enough to increase the samples’ moisture due to the hydrophobic nature of lignin (31.03%), which was not removed during the mechanical pulping process. The lowest moisture content corresponded to the control board (9.00 ± 0.55%), indicating that the addition of fibers increased the permeability of concrete materials, mainly due to their relatively high moisture absorption and hydrophilic behavior, which is attributed to the presence of hemicellulose and the porous nature of the materials (Komuraiah et al., 2014; Choi, 2022; Hamada et al., 2023).

The comparability of the volumetric swellings of FCC is contrary to that expected (the addition of OPMF should increase the swelling of the composite) (Adamu et al., 2022). This indicates that the FCC were not negatively affected by fiber with regard to swelling. The OPMFs’ 15.8 mm length could reduce heterogeneity in the samples and prevent surface cracking, which can lead to excessive water absorption and, subsequently, volumetric swelling (Cárdenas-Oscanoa et al., 2020; Córdova Contreras et al., 2020; Momoh & Osofero, 2020).

Water absorption is a physical property that is related to porosity; a lower water absorption increases the durability and stability of concrete (Jamshaid et al., 2022). The addition of 3% OPMF to cementitious composites has been generally found to reduce the water absorption of FCC (Jamshaid et al., 2022). However, other studies have yielded contradictory results (Kareche et al., 2020; Adamu et al., 2022).

The porosity at the interface increased as the fiber loading increased (Jamshaid et al., 2022; Bellel & Bellel, 2023). A possible explanation is that the interfacial transition zone (ITZ) of the FCC matrix, which is characterized by a high porosity, formed a gap (debonding) around the lignocellulosic fiber (Savastano et al., 1999; Ali et al., 2022). Furthermore, a higher porosity and a larger number of voids could influence strength properties, resulting in increased water absorption and reduced density (Cipra-Rodriguez et al., 2022; Fernando et al., 2023).

Mechanical properties

The increase in OPMF content tends to reduce the compressive strength of the materials, or to augment the thickness reduction (Lertwattanaruk & Suntijitto, 2015), as fibers typically exhibit a lower density than the matrix. The lowest value was achieved by the FCC with 3% OPMF, which agrees with other studies (Raut & Gómez, 2016; Alatshan et al., 2017; Adamu et al., 2022). The addition of 1 and 3% (by volume) of natural fibers in cement composites has been demonstrated to enhance the properties of cement mortars and concrete (Momoh & Osofero, 2020). Furthermore, an increased fiber loading fraction can deteriorate mechanical properties (Jamshaid et al., 2022).

The flexural behavior of the FCC depends on the type, length, diameter, aspect ratio, and texture of the fibers (Khorami & Ganjian, 2011). Nevertheless, the failure of a FCC is highly influenced by size and the cross-section of the lignocellulosic fiber, which is not uniform (Ishak et al., 2013). The length-to-diameter ratio (i.e., aspect ratio) of a fiber has significant effects on the properties of composites (Altez Basaldúa et al., 2020). Short oil palm fibers can be used as additive fillers in polymer composites to enhance mechanical properties (Arao et al., 2015). However, the aspect ratio of the fibers used in this study (48) was less than that observed in Asyraf et al. (2022) (155.5). Moreover, the addition of oil palm fiber has no effect on the chemical composition of the matrix, thus preventing any interference with the curing of the material (Bellel & Bellel, 2023).

Cement concrete without fiber is brittle and exhibits lower tensile strength, limited ductile properties, and limited resistance to cracking. The addition of fiber in concrete can arrest the propagation of microcracks while increasing its strength (Jamshaid et al., 2022). However, our results regarding mechanical properties showed equal or lower strength values when adding OPMF to FCC. The inferior performance of the FCCs containing 6 and 9% OPMF with respect to the control board may be attributed to the decomposition of the fibers’ lignin within the alkaline matrix (Savastano et al., 2005), promoting the presence of voids. It is worth highlighting that the hydroxyl groups available on the surface of the cellulose serve as the primary means through which fibers and cement bond together (Coutts, 2005). In addition, the homogeneous dispersion of fibers in the matrix is a crucial factor to develop FCC with well-balanced mechanical properties while incorporating plant fibers. Hence, the dispersion of fibers can be improved by increasing the water quantity to the optimal value (Fernando et al., 2023).

The physical and mechanical properties and the chemical components of OPMF may vary depending on factors such as the weather, soil conditions, fertilization, plant age, etc. (Bajuri et al., 2017). In this vein, the findings of each research study may be unique and therefore cannot be extrapolated to other work (Khorami & Ganjian, 2011). FCC can be employed in roofing, internal or external walls, façades, internal or external pavements, and flooring slabs as a sustainable construction material for the future (Khorami & Ganjian, 2011; Jamshaid et al., 2022). In this study, the optimal performance was achieved by FCC with 3% OPMF, which aligns with the findings of Abdalla et al. (2023) and Khorami & Ganjian (2011), who found a maximum of 4% to be the optimal replacement of natural fibers to enhance the properties of FCC in laboratory settings.

Scanning electron microscopy

The fibers and fiber bundles in the FCCs (Figures 3b to 3d) are readily discernible in the analyzed micro-images, unlike the case of the control board (Figure 3a). The presence of fibers and fiber bundles increases FCC porosity (Bellel & Bellel, 2023). Conversely, the observed cavities are characteristic of porous materials such as cement. However, the presence of gaps in the transition zone or in fiber tunnels could potentially render some points fragile or negatively alter the structure of the FCC (Alencar et al., 2023), which justifies the lower strength of the samples with 6 and 9% OPMF.

Figure 3 shows some fiber tunnels, which are the result of a rupture mechanism known as fiber pulling. Additionally, fiber breaking was observed in the majority of fibers (Khorami & Ganjian, 2011).

An adequate curing of the FCCs was observed, as indicated by the minimal number of microcracks in the internal structure (Figure 4). Furthermore, there were voids in the ITZ, which can be attributed to inadequate interfacial bonds, likely because of the heterogeneous fiber surface resulting from the mechanical pulping process (Feng et al., 2023). Fiber swelling tendencies and non-alkaline pre-treatments of OPMF have been found to attenuate interface efficiency in FCCs (De Souza Castoldi et al., 2023). The dissimilar void distribution between an individual fiber (Figure 4a) and a bundle of them (Figure 4b) is due to the fibers’ different diameters (Alatshan et al., 2017). A homogeneous dispersion of fiber is required to manufacture FCC with well-balanced mechanical properties (Fernando et al., 2023).

Fourier transform infrared spectroscopy

The FTIR graph illustrates the spectra of the FCCs and the OPMF, which was reported in a study on bamboo fiber-reinforced cement composite (Alencar et al., 2023). The differing vibration intensities (peaks) observed between spectra are dependent on the fiber content (Feng et al., 2023).

The 3708-3782 cm-1 band is a result of the stretching vibration of OH groups, which originate from the hydroxyls present in the cellulose molecules, the primary means by which fibers and cement bond together, and the vibration of the hydrogen bridge, characteristic of intermolecular bonds between cellulose chains (Coutts, 2005; Feng et al., 2023; Jiang et al., 2023; Liu et al., 2023; Arango-Pérez et al., 2024). This band also reveals the presence of functional groups such as phenols, alcohols, and water in hemicellulose polymers, lignin, and polyphenols (Alencar et al., 2023).

The vibration in the 2357-2360 cm-1 band is related to the presence of CO2, which can easily adhere to the surface of lignocellulosic materials through the adsorption phenomenon (Arango-Perez et al., 2024).

The peaks in the 1594-1596 cm-1 band are associated with the vibration of the acetyl and uronic ester bonds of hemicellulose and with ester linkage in carboxylic groups of lignin and/or hemicellulose. Furthermore, these peaks indicate the C-H deformation of lignin and the C=C bonds originating from its aromatic rings (Alencar et al., 2023; Ezugwu et al., 2023; Jiang et al., 2023; Arango-Pérez et al., 2024). The 1450 cm-1 band indicates C-H deformation in cellulose/hemicellulose (Alencar et al., 2023).

The 1000 cm-1 band can be attributed to deformations in the C-H and C-O couplings present in cellulose (Alencar et al., 2023; Ezugwu et al., 2023). The 865-867 cm-1 region is associated with the stretching vibration of the Si-O bonds of the SiO4-4 tetrahedron of the C-S-H present in cementitious matrices (Alencar et al., 2023). Conversely, the peaks observed in the 800-900 cm-1 band are attributed to C-OH deformation of the β-glucosidic bonds present in the hemicellulose of plant fibers (Alencar et al., 2023).

CONCLUSIONS

Fiber cement composites containing 3, 6, and 9% of oil palm mesocarp fiber were produced. The addition of up to 9% OPMF reduced density by 10.17%, porosity by 6.60%, and the modulus of rupture by 34.62%. There was an increase in the short-term water uptake (3.41%), as well as in thickness reduction (132.53%). This was due to lower fiber density and moisture absorption capacity. In addition, there were no significant differences between the FCCs with regard to volumetric swelling and water absorption. The FCC containing 3% OPMF achieved the optimal physical and mechanical performance due to its higher density and its lower water absorption and porosity in comparison with the control board (0% OPMF).

Acknowledgements

ACKNOWLEDGEMENTS

The authors acknowledge the support provided by Mg. Sc. Deysi Guzmán, Eng. Sergio Arango, the Forest Chemistry Laboratory, the Pulp and Paper Laboratory, and the Language Center of Universidad Agraria La Molina.

REFERENCES

Appendix 1.

An * within a column with different letters means that there is a significant difference at p < 0.05 (Tukey test). The standard deviation is also shown

Appendix 1. : Physical and mechanical properties of FCC with different OPMF proportions

Licencia

Derechos de autor 2024 Colombia forestal

Esta obra está bajo una licencia internacional Creative Commons Atribución-CompartirIgual 4.0.

Colombia Forestal conserva los derechos patrimoniales (copyright) de las obras publicadas, y favorece y permite la reutilización de las mismas bajo la licencia Creative Commons Atribución-CompartirIgual 4.0 Internacional por lo cual se pueden copiar, usar, difundir, transmitir y exponer públicamente, siempre que:

Se reconozcan los créditos de la obra de la manera especificada por el autor o el licenciante (pero no de una manera que sugiera que tiene su apoyo o que apoyan el uso que hace de su obra).