DOI:

https://doi.org/10.14483/23448350.19816Published:

01/02/2023Issue:

Vol. 46 No. 1 (2023): January-April 2023Section:

Ciencias Básicas y EducaciónSmart Greenhouse and Agriculture 4.0

Invernadero inteligente y agricultura 4.0

Keywords:

controlled agricultural environments, emergent communication technologies, precision agriculture, smart sensors (en).Keywords:

ambientes agrícolas controlados, tecnologías emergentes de comunicación, agricultura de precisión, monitoreo remoto, sensores inteligentes (es).Downloads

References

Achur, Y., Ouammi, A., Zejli, D. (2021). Technological progresses in modern sustainable greenhouses cultivation as the path towards precision agriculture. Renewable and Sustainable Energy Reviews, 147, 111251. https://doi.org/10.1016/j.rser.2021.111251 DOI: https://doi.org/10.1016/j.rser.2021.111251

Agrofercol (2018). Las frutas colombianas se abren paso en el mundo. https://www.agrofercol.com/las-frutas-colombianas-se-abren-paso-en-el-mundo/

Akkaş, M., Sokullu, R. (2017). An IoT-based greenhouse monitoring system with Micaz motes. Procedia Computer Science, 113, 603-608. https://doi.org/10.1016/j.procs.2017.08.300 DOI: https://doi.org/10.1016/j.procs.2017.08.300

Arias, F. (2018). Sector bananero crece en exportaciones, área cultivada y productividad. https://www.elcolombiano.com/negocios/bananeros-presentan-buen-balance-en-2017-FY8463412

Azaza, M., Tanugast, C., Fabrizio, E., Mami , A. (2016). Smart greenhouse fuzzy logic based control system enhanced with wireless data monitoring. ISA Transactions, 61, 297-307. https://doi.org/10.1016/j.isatra.2015.12.006 DOI: https://doi.org/10.1016/j.isatra.2015.12.006

Banco de la República (2012). Agricultura. En P. Bell (Ed.), Colombia: manual comercial e industrial (pp. 207-244). Banco de la República

Barroso, A. (2015). Control y monitorización de un invernadero a través de una aplicación móvil [Tesis de Grado]. Universidad Politécnica de Madrid. https://core.ac.uk/download/pdf/148675384.pdf

Calderón, N. (2017). Las 9 frutas colombianas más apetecidas por los extranjeros. https://www.colombiamegusta.com/las-9-frutas-colombianas-mas-apetecidas-los-extranjeros/

Cobos, C. A., Timaná, J. A., Valencia, R. (2008). Sistema de soporte a la toma de decisiones para procesos de germinación y cultivos en invernaderos. Biotecnología en el Sector Agropecuario y Agroindustrial, 6(1), 22-31

Eberhart, R., Kennedy, J. (1995). A new optimizer using particle swarm theory. Sixth International Symposium on Micro Machine and Human Science, Nagoya, Japan. https://doi.org/10.1109/MHS.1995.494215 DOI: https://doi.org/10.1109/MHS.1995.494215

FAO (2009). La agricultura mundial en la perspectiva del año 2050. Foro de Expertos de Alto Nivel. https://www.fao.org/fileadmin/templates/wsfs/docs/Issues_papers/Issues_papers_SP/La_agricultura_mundial.pdf

FAO (2013). Good agricultural practices for greenhouse vegetable crops. Food and Agriculture Organization of the United Nations. https://www.fao.org/3/i3284e/i3284e.pdf

FAO (2019). El estado mundial de la agricultura y la alimentación. Progresos en la lucha contra la pérdida y el desperdicios de alimentos. Food and Agriculture Organization of the United Nations

Hahn, F. (2011). Fuzzy controller decreases tomato cracking in greenhouses. Computers and Electronics in Agriculture, 77(1), 21-27. https://doi.org/10.1016/j.compag.2011.03.003 DOI: https://doi.org/10.1016/j.compag.2011.03.003

Kaneda, Y., Ibayashi, H., Oishi, N., Mineno, H. (2015). Greenhouse environmental control system based on SW-SVR. Procedia Computer Science, 60, 860-869. https://doi.org/10.1016/j.procs.2015.08.249 DOI: https://doi.org/10.1016/j.procs.2015.08.249

La Opinión (2017). Lluvias afectan cultivos y vías en 10 municipios de Norte de Santander. La Opinión. https://www.laopinion.com.co/region/lluvias-afectan-cultivos-y-vias-en-10-municipios-de-norte-de-santander

Marín, E., Urdinola, Z., Chud, V. (2019). Innovación y desarrollo tecnológico en banco de alimentos para mejorar la seguridad alimentaria de la subregión Norte del Valle del Cauca [Tesis de grado]. Universidad del Valle

Nawandar, N., Satpute, V. (2019). IoT based low cost and intelligent module for smart irrigation system. Computers and Electronics in Agriculture, 162, 979-990. https://doi.org/10.1016/j.compag.2019.05.027 DOI: https://doi.org/10.1016/j.compag.2019.05.027

OECD (2018). Revisión de políticas agrícolas de la OCDE: Colombia 2015. OECD. https://doi.org/10.1787/9789264307063-es DOI: https://doi.org/10.1787/9789264307063-es

Orsolin, C., Valle, J., Müller, G. (2022). Impacts of digitalization on value creation and capture: Evidence from the agricultural value chain. Agricultural Systems, 201, e103468. https://doi.org/10.1016/j.agsy.2022.103468 DOI: https://doi.org/10.1016/j.agsy.2022.103468

Rejeb, A., Rejeb, K., Abdollahi, A., Al-Turjman, F., Treiblmaier, H. (2022). The interplay between the Internet of Things and agriculture: A bibliometric analysis and research agenda. Internet of Things, 19, e100580. https://doi.org/10.1016/j.iot.2022.100580 DOI: https://doi.org/10.1016/j.iot.2022.100580

Revathi, S., Sivakumaran, N. (2016). Fuzzy based temperature control of greenhouse. IFAC-PapersOnLine, 49(1), 549-554. https://doi.org/10.1016/j.ifacol.2016.03.112 DOI: https://doi.org/10.1016/j.ifacol.2016.03.112

Rodríguez, J., Montoya, A., Rodriguez, C., Hoyos, J., Corrales, J. (2021). IoT-Agro: A smart farming system to Colombian coffee farms. Computers and Electronics in Agriculture, 190, e106442. https://doi.org/10.1016/j.compag.2021.106442 DOI: https://doi.org/10.1016/j.compag.2021.106442

Saud, G., Foteini, B., Esmail, E., Seifelislam, G., Rashwan, M., Abdelhalim, A., Ismail, S. (2019). Design challenges of agricultural greenhouses in hot and arid environments – A review. Engineering in Agriculture, Environment and Food, 12(1), 48-70. https://doi.org/10.1016/j.eaef.2018.09.004 DOI: https://doi.org/10.1016/j.eaef.2018.09.004

Sierra, J. F. (2017). Uso TIC agrícola aún tiene ajustes en la cosecha. El Colombiano. https://www.elcolombiano.com/negocios/uso-tic-agricola-aun-tiene-ajustes-en-la-cosecha-FX7752304

Sri Jahnavi, V., Ahamed, S. (2015). Smart wireless sensor network for automated greenhouse. IETE Journal of Research, 61(2), 180-185. https://doi.org/10.1080/03772063.2014.999834 DOI: https://doi.org/10.1080/03772063.2014.999834

Tao, W., Zhao, L., Wang, G., Liang, R. (2021). Review of the internet of things communication technologies in smart agriculture and challenges. Computers and Electronics in Agriculture, 189, e106352. https://doi.org/10.1016/j.compag.2021.106352 DOI: https://doi.org/10.1016/j.compag.2021.106352

Tzounis, A., Katsoulas, N., Bartzanas, T. (2017). Internet of Things in agriculture, recent advances and future challenges. Biosystems Engineering, 164, 31-48. https://doi.org/10.1016/j.biosystemseng.2017.09.007 DOI: https://doi.org/10.1016/j.biosystemseng.2017.09.007

Zeed, A. T. A., Ali, A., Al-Baghdadi, M. A. R. S. (2019). Cost-effective IoT-based control system for smart greenhouses powered by solar energy. International Energy and Environment Foundation (IEEF), 10(3), 103-109

How to Cite

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Download Citation

Recibido: de julio de 2022; Aceptado: de octubre de 2022

Abstract

In Colombia, agricultural exports have become notoriously prevalent in recent years, causing the creation of new methods capable of increasing production in order to meet the global demands. A very efficient option is the use of greenhouses, given their low building cost, ease of construction, ability to protect crops from natural phenomena and plagues, and the possibility to keep the internal temperature steady during day and night, thus allowing crops to grow fast and healthy. Nowadays, advancements in electronics have allowed boosting the positive effects of these environments, which is why this document introduces a procedure for the implementation of an automated pyramid-type greenhouse, utilizing techniques related to Precision Agriculture (PA) and based on concepts related to the Internet of Things (IoT) for remote monitoring through emerging communication technologies such as the NFRL2401 cards and the Arduino Nano and Mega boards. Inside the greenhouse, variables such as temperature and ambient humidity are measured and controlled via the PCE-P30U Universal Input Signal Converter Data Logger, while ground humidity is monitored by ZD510 capacitive sensors. Outside, variables such as temperature, ambient humidity, negative and positive pressure, and wind speed are measured. Data obtained is taken wirelessly to the server using Windows Server 2019 Datacenter, with Broker MQTT EMQ-X services and MYSQL databases, providing a suitable and efficient environment for agricultural research processes. With the procedure developed in this document, a baseline is proposed for the implementation of a smart greenhouse that can be replicated and used as a test system for smart sowing processes, adapting to the different climate and production conditions of the country.

Palabras clave:

controlled agricultural environments, emerging communication technologies, precision agriculture, remote monitoring, smart sensors.Resumen

En Colombia, la exportación agrícola ha crecido en los últimos años, motivando la creación de nuevos métodos que incrementen la producción para satisfacer la demanda mundial. El uso de invernaderos es una opción bastante eficiente, dados sus bajos costos de construcción, su habilidad para proteger cultivos de fenómenos naturales y plagas, y la posibilidad de mantener la temperatura interna estable durante el día y la noche, lo cual hace que el fruto crezca rápido y saludable. En la actualidad, los avances en electrónica han permitido potencializar los efectos positivos de estos espacios, por lo cual en este texto se presenta un procedimiento para la implementación de un invernadero automatizado de tipo piramidal, utilizando técnicas relacionadas con la Agricultura de Precisión (AP) y partiendo de conceptos relacionados con el internet de las cosas (IoT) para el monitoreo remoto a través de tecnologías emergentes de comunicación como las tarjetas NFRL2401 y placas Arduino Nano y Mega. Al interior del invernadero se miden y controlan variables como la temperatura y humedad del ambiente por medio de la PCE-P30U Universal Input Signal Converter Data Logger, mientras que la humedad del suelo es monitoreada por medio de sensores capacitivos ZD510. En el exterior, se miden variables como la temperatura, la humedad del ambiente, presión positiva y negativa y la velocidad del viento. Los datos obtenidos son llevados inalámbricamente a un servidor que utiliza el Windows Server 2019 Datacenter, con servicios Broker MQTT EMQ-X y bases de datos MYSQL, propiciando un ambiente apto y eficiente para la realización de procesos en investigación agrícola. Con el procedimiento desarrollado en este documento, se propone una línea de base para la implementación de un invernadero inteligente que pueda ser replicado y sirva como sistema de prueba en procesos inteligentes de siembra, adaptándose a la diferentes condiciones climáticas y productivas del país.

Keywords:

agricultura de precisión, ambientes agrícolas controlados, monitoreo remoto, sensores inteligentes, tecnologías emergentes de comunicación..Resumo

Na Colômbia, as exportações agrícolas cresceram nos últimos anos, motivando a criação de novos métodos que aumentam a produção para atender a demanda global. O uso de estufas é uma opção bastante eficiente, dado o baixo custo de construção, a capacidade de proteger as lavouras de fenômenos naturais e pragas e a possibilidade de manter uma temperatura interna estável durante o dia e a noite, o que faz com que a fruta cresça rápido e saudável. Na atualidade, os avanços da eletrônica têm possibilitado potencializar os efeitos positivos desses espaços, razão pela qual este texto apresenta um procedimento para a implantação de uma estufa automatizada do tipo pirâmide, utilizando técnicas relacionadas à Agricultura de Precisão (AP) e a partir de conceitos relacionados à Internet das Coisas (IoT) para monitoramento remoto por meio de tecnologias de comunicação emergentes, como placas NFRL2401 e placas Arduino Nano e Mega. Dentro da estufa, variáveis como temperatura ambiente e umidade são medidas e controladas por meio do Data Logger Conversor de Sinal de Entrada Universal PCE-P30U, enquanto a umidade do solo é monitorada por meio de sensores capacitivos ZD510. No exterior, são medidas variáveis como temperatura, humidade ambiente, pressão positiva e negativa e velocidade do vento. Os dados obtidos são levados sem fio para um servidor que utiliza o Windows Server 2019 Datacenter, com serviços Broker MQTT EMQ-X e bancos de dados MYSQL, proporcionando um ambiente adequado e eficiente para a realização de processos de pesquisa agropecuária. Com o procedimento desenvolvido neste documento, propõe-se uma linha de base para a implantação de uma estufa inteligente que pode ser replicada e servir como sistema de teste em processos de plantio inteligentes, adaptando-se às diferentes condições climáticas e produtivas do país.

Palavras-chaves:

agricultura de precisão, ambientes agrícolas controlados, monitoramento remoto, sensores inteligentes, tecnologias de comunicação emergentes..Introduction

Colombia is a country whose global-scale fruit exportation has grown in recent years, as evidenced by the fruit and vegetable fair (MacFruit) of the year 2018 (Agrofercol, 2018). Banana crops generate the most profits, as proven by their yearly performance of well over 811 million dollars, followed by cape gooseberry, gulupa, honey glow pineapple, and the Tahiti Lemon (Calderón, 2017; Arias, 2018). This varied crop production is made possible thanks to the geography and topography of the country, which implies the existence of different soils and climates (thermal floors), making the country a great place for the production of a variety of fruits. Valle del Cauca is a department with great richness in agricultural production, as evidenced by a study conducted by an interdisciplinary group of teachers from Universidad del Valle and Universidad Tecnológica de Pereira within the framework of the macro-project Innovación y desarrollo tecnológico en banco de alimentos [Food bank innovation and technological development] (Marín et al., 2019), which yielded very encouraging figures regarding the diversity and amount of agricultural products that the north subregion of Valle del Cauca has to offer. Products such as papaya, orange, guava, banana, lemon, tangerine, cantaloupe, pumpkin, yucca, tomato, onion, and cabbage are all part of the 8200 monthly tons of fruit production and the 296 monthly tons of vegetables (Marín et al., 2019), showing very diverse and rich prospects for agricultural production in the department.

Nevertheless, with the aforementioned figures, and in light of the fact that Colombia is a developing country with great agricultural potential, it is important to mention that population growth and climate change imply the need to gradually redirect the current agricultural practices. The Food and Agriculture Organization of the United Nations (FAO), in a document titled The state of food and agriculture in the world (FAO, 2009), predicts that the global population will reach 8 billion in 2025 and 9.6 billion in 2050. This means that the agricultural production must increase by 70% worldwide by 2050 (FAO, 2019). Overpopulation and the growing demand for high quality products create the need to modernize and intensify the already existing agricultural practices, as well as the need to make more efficient use of water and other related resources (Tzounis et al., 2017).

In addition, Colombia faces three problems regarding its agricultural production. The first is related to its unrelenting weather, which causes rains throughout a big portion of the year, severely affecting crops due to the excess of water, altering their quality, and even destroying the crop altogether, which makes harvesting difficult in the best of cases (La Opinión, 2017). The second problem is caused by the country’s mountainous topography, as flat areas to harvest are rare. This reduces production, makes mobility between crops difficult, and increases the risk of landslides during periods of rain, damaging many hectares of crops (Banco de la República, 2012). The third problem is associated to how several farmers all over the nation continue to employ outdated harvesting techniques and are not familiar with or reject the use of more modern methods of agriculture (due to a lack of interest or financial resources) such as the use of technology and other advancements (Sierra, 2017), which losses and slows down progress in this sector (Cobos et al., 2008; Orsolin et al., 2022).

With this in mind, and remembering that Colombia is a country rich in agricultural production, as well as the fact that it is currently necessary to make advancements in the field of agricultural technologies, the use of greenhouses has become a popular method that allows upgrading production, as it allows harvesting throughout year, as crops are placed in an enclosed space that generates a controlled microclimate, thus enabling the sprouting of crops even when the season is unfavorable or they not in their thermal floor (Achur et al., 2021). Additionally, this type of system protects vegetation from the plagues and diseases that spread in the environment (Barroso, 2015). It is also worth noting that the cost of construction of a greenhouse is not high, which may encourage farmers to invest in them.

One of the most promising, recent concepts related to the sustainable production of food is Precision Agriculture (PA) (Tzounis et al., 2017; Rodríguez et al., 2021). PA implies innovation, technological advancement, and research, and its purpose is to optimize and enhance agricultural processes in order to guarantee maximum productivity, establishing strategies to use the necessary supplies in the required amount, at the adequate place and at the opportune moment, adapting to the crops and the soil’s needs. The characteristics of this approach include optimal energy consumption (renewable energies), the rational use of water and chemical products (sustainability), and real-time measurements via IoT Systems (Internet of Things), among others. This allows large-, medium-, and small-scale producers to make use of technology in order to perfect their agricultural processes (Rejeb et al., 2022; Tao et al., 2021).

Nowadays, many applications are in need of technological development to make the sector competitive. This is where advances in technology play an important role. Currently, in the agricultural sector, important advancements have been made which are based on innovation and emerging technologies, as is the case of the work by Zeed et al. (2019), who integrate sensors through a wireless network while working under the concept of PA. The authors present the way in which through an Arduino Uno handles information processing and internet connectivity. The system was programmed in such a way that the data gathered from sensors is transmitted to a database server while handling the measurement and continuous control of variables that are incidental in the process. In a similar fashion, in India, Nawandar and Satpute (2019) developed an intelligent watering system based on IoT advancements. They state that their system can interact with the user, is configured once for the estimation of the watering program, and uses neural networks for data processing. The system uses MQTT and HTTP to keep the user informed about the current situation of the crops, even at great distances. Azaza et al. (2016) propose an intelligent variable control system for greenhouses which uses fuzzy logic and includes wireless information monitoring, thus providing access to data in real time. The proposed control system was validated experimentally and showed to be efficient at saving water and power. Likewise, Revathi and Sivakumaran (2016) propose controlling the internal temperature of a greenhouse by using fuzzy logic. In order to increase the degree of automation of the fuzzy control system, they developed an “almost optimal” controller synthesis strategy via the particle swarm optimization (PSO) technique (Eberhart and Kennedy, 1995). In Universidad Autónoma de Chapingo, Mexico, a project related to the automation of a greenhouse for harvesting tomatoes was developed (Hahn, 2011). This project involves controlling a motor for the opening and closing a polyshade window through PWM modulation, in accordance with the incident characteristics of sunrays. Furthermore, watering control is performed through fuzzy logic. The central control system is based on a ATM89C51 microcontroller (Hahn, 2011). In Japan, Kaneda et al. (2015) proposed an environmental control system for an intelligent greenhouse that is based on sliding windows vector support machines (SW-SVR). The proposed system handles the aforementioned control with accurate predictions in real time. SW-SVR is a new automatic learning algorithm for predicting temporary series of data. This model automatically and periodically adjusts to its surroundings and predicts time-series data with high accuracy and low computing complexity. Additionally, in Turkey, Akkaş and Sokullu (2017) presented a WSN prototype consisting of MicaZ nodes, which is used to measure temperature, light, pressure, and humidity in greenhouses. The measurement data are shared with the help of the IoT. With this system, farmers can control variables from their mobile phones or computers if they have Internet. Other advancements include the one shown by Sri Jahnavy and Ahamed (2015), which involves the design of a wireless sensor network that provides real-time monitoring of the temperature, humidity, and soil humidity of a greenhouse while using a central micro-controlled system and communication between sensors via Zigbee. Data records can be created and uploaded to the Internet to be reviewed from any location.

The Latin American countries with the highest technological advancement in the agricultural sector are Argentina and Brazil. At a global scale, there are Holland and the United States, whose advancements are framed within the so-called Industry 4.0 and include Big Data initiatives, systems based on the Internet of Things (IoT), and artificial intelligence (AI) applications. Colombia, despite its agricultural nature, has very low levels of crop productivity regarding Information and Communications Technologies (ICTs), as there are no official indicators of penetration and production efficiency (Sierra, 2017). It is also important to mention that research and agricultural development (R&D) and the transfer of agricultural knowledge have not been successfully exploited, which is reflected on the low competitiveness and productivity of the agricultural sector of the country (OECD, 2018).

Considering the current needs of the Colombian agricultural sector, as described in previous paragraphs, this work propones the development of a space for agricultural research based on the implementation of an automated greenhouse by making use of PA, with developments based on the Internet of Things (IoT) for remote monitoring through intelligent sensors connected to an Internet network.

This technological development makes the following contributions:

-

It presents a space for agricultural research with controlled environments (intelligent pyramid-type greenhouse) 10 m in length and 4.2 m in width, with four planting beds 3 m in length and 2 m in width.

-

Inside the greenhouse, the measurement of variables such as temperature and ambient and soil humidity is available through low-cost sensors that are wirelessly connected to a network.

-

Outside the greenhouse, it is possible to measure temperature, ultraviolet radiation (UV), rain, and wind via a meteorological station.

-

The information obtained is concentrated and sent to the cloud, allowing for real-time data recording and visualization. Furthermore, a locally configured server is used for data storage.

-

The watering and aspersion system is manually controlled on-site or programmed remotely through the Web or a mobile app, providing a suitable and efficient environment for agricultural research.

This document is firstly structured with an introduction that explains the context of the problem addressed for the case of agriculture in controlled environments, the state-of-the-art identifying works with significant developments based on innovation and emerging communication technologies in applications in the agricultural sector around the world. With the above, the focus and the contributions generated are defined taking into account the actual needs of the Colombian agricultural industry and the problems. Following, the methods used for the realization of the proposed activities are structurally defined as follows: Survey of the physical structure of the greenhouse, installation of the sensors used and metrological station, establishment of the controlled environment, and adequacy and installation of the web server. In addition, the considerations said before and the test scenes are presented. Then, the results obtained in the Technological Development based on the description of the hardware and software implemented, in addition to the physical space obtained. Finally, the work's most important discussions and conclusions are presented, complemented with future works analyzed from the research context.

Methodology

This section outlines the different stages of the project.

Building the Greenhouse

The first stage involved building the physical structure of the greenhouse, which has a surface and a pyramidal roof, whose use is very common, as it provides uniform radiation incidence throughout a big portion of the year. The greenhouse also has a 6-caliber plastic layering used to protect crops from the outside and solar rays. This guarantees heat and distant infrared radiation (FAO, 2013), factors that positively affect photosynthesis and evapotranspiration in crops (Saud et al., 2019). Additionally, the greenhouse has an antitrips net enclosure that provides protection against insects and animals. Regarding the location of the greenhouse, it was kept in mind that it needed to receive sunlight for most of the day. Figure 1 shows the geospatial location of the greenhouse in Universidad del Valle (Cartago, Colombia).

Figure 1: Geospatial location of the greenhouse.

Installing the Sensors and the Weather Station

Inside the greenhouse, temperature and ambient humidity are measured through the PCE Instruments Tactile Visualization Console, and soil humidity is measured using three ZD510 capacitive sensors for each planting bed, each one connected in a tree topology, and NFRL2401 transceiver modules. Additionally, a NRF24L01 concentrator card with a transceiver module, which records the measurements in the MQTT EMQX server via a network with a LAN W5100 card that sends the information wirelessly to the cloud, allowing connectivity through the IoT. Outside, through a PCE-FWS 20N weather station with transmission speeds of , , and , the following variables are measured and recorded in the cloud: temperature, humidity, absolute and relative pressure, wind speed, and wind direction. The visualization console and the station are shown in Figure 2.

Figure 2: Visualization console and metereological station.

Establishing the Controlled Environment

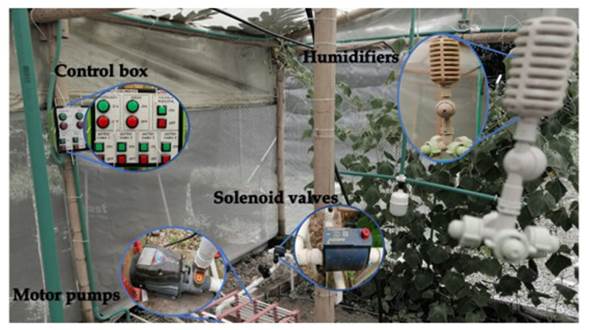

An environment with controlled temperature and soil and ambient humidity was installed, combining cooling technologies such as humidifiers and drip irrigation systems in each of the planting beds. These are manipulated independently through solenoid valves with the ACUANETplus reference at 24 V AC. The supply of water and organic fertilizer is controlled by two PEARL motor pumps of and . Figure 3 shows the humidifiers and the drip irrigation system, including the solenoid valves and motor pumps. Additionally, the on-site manual control box, with Internet connectivity, records activation or deactivation in the MQTT EMQx server and the database, thus providing a controlled environment.

Figure 3: Controlled environment system.

Adjusting and Installing the Web Server

In this stage the installation and configuration of the server team was performed, which involved the Windows Server 2019 Datacenter operating system, MQTT EMQ-X Broker services, and a MYSQL database, in charge of addressing requests made from mobile devices, web services, sensors within the greenhouse, and the meteorological station. These devices, all configured with the MQTT protocol of the IoT, record data in real time, as long as there is Internet connectivity. This connectivity is ensured by TL-WA5210G CPE TP-LINK wireless high-power access points at for exteriors, connection between the greenhouse, and the remote monitoring station where the server is located.

Given the scale of the implemented greenhouse and the amount of the measured variables, a MySQL database was used. However, it is important to note that, when the number of sensed variables or greenhouses increase, it is appropriate to apply NoSQL database.

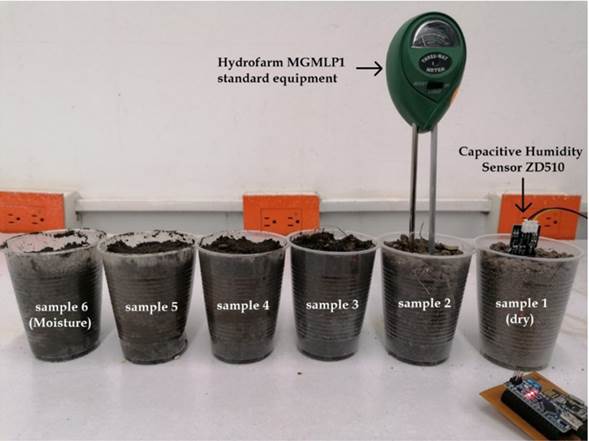

Test Scenarios and Considerations

With the proposed methodology, the measurements acquired during the calibration of the ZD510 capacitive soil humidity sensors were validated through a process of characterization that involves an MGMLP1 Hydrofarm as a pattern, whose humidity readings are recorded in a scale of 0 (dry) to 10 (humid). Three experiments were performed with six soil samples, with an average mass of each. Each sample was humidified with of water in a cumulative fashion, starting from a dry state and transitioning to a humid one. Figure 4 shows the characterization conditions.

Figure 4: Soil humidity sensor calibration.

Results and Discussion

Following the proposed methodology, the general objective of the project is to implement a smart, automated greenhouse based on IoT systems, with the characteristics described below.

The physical structure of a greenhouse was built with a pyramidal roof made out of guadua, with four planting beds, electrical energy, access to an aqueduct for the storage of water in a reserve tank, individual illumination for each bed ( LED lightbulbs), and Internet access, as shown in Figure 5.

Figure 5: Physical internal and external structure of the greenhouse.

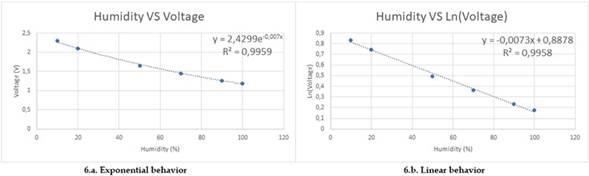

To calibrate the ZD510 soil humidity sensor, the graph shown in Figure 6a was initially obtained. This Figure depicts an exponential behavior according to the equation , as well as a Pearson ratio coefficient of . After performing the linearization process, the graph shown in Figure 6b was obtained, as given by the equation , with a correlation of 0.9959.

Figure 6: Soil humidity sensor calibration.

Three ZD510 capacitive humidity sensors were installed in each planting bed, each one connected independently to an Arduino Nano board and an NFRL2401 communication board, which allows sending information wirelessly to a central processing unit based on Arduino Mega with a server connection. The central part of the developed code that allows the floor humidity sensor to receive, process, and send the obtained information is shown below.

void loop() {

network.update();

unsigned long now = millis();

if (now - last_sent >= interval)

{

last_sent = now;

unsigned long potValue = analogRead(A0);

unsigned long Volt = potValue/1023*5.0;

unsigned long Hume dad = (0.8878-(log(volt)))/0.0073; //Equation characteristic

RF24NetworkHeader header(master00); // (Address where the data is going)

bool ok = network.write(header, &Humedad, sizeof(Humedad)); // Send the data

}

}

By means of the PCE Instruments visualization console, it was possible to record and store the measurements of temperature and ambient humidity inside the greenhouse. The data obtained were sent to the cloud via communication between the PCE visualitzation console and a Raspberry PI4 that transmits to the server databases through the Internet. The operating system can be found in the following web address:

https://cumuluswiki.org/a/Raspberry_Pi_Image #Installing_the_Image

The connectivity of the meteorological station was configured in such a way that it would allow recording data in the EMQx server every 2 min. The central part of the developed code for this stage is shown below.

client.on('message', (topic, message, packet) =>{console.log('Mensaje recibido: ' + message.toString() + '\nEn tópico: ' + topic)

// Position of external variables

posWthrOut = parseInt(message.toString().search('temp'));

posHumOut = parseInt(message.toString().search('humidity'));

posWgust = parseInt(message.toString().search('wgust'));

posPress = parseInt(message.toString().search('pressure'));

lastPosStr = parseInt(message.toString().search('}'));

console.log('Pos WthrOut:' + posWthrOut + " " + 'Pos HumOut:' + posHumOut + " " + 'Pos WthrOut:' + posPress);

// Extraction of variables

wthrOut =parseFloat(message.toString().substring(posWthrOut+6,posHumOut-2));

humOut = parseFloat(message.toString().substring(posHumOut+10, posWgust-2));

wgust = parseFloat(message.toString().substring(posWgust+7,posPress-2));

Atmpress = parseFloat(message.toString().substring(posPress+10,lastPosStr));

console.log("WthrOut: " + wthrOut + ", humOut: " + humOut + ", Wgust: " + wgust + ", Press: " + Atmpress);

// Updating the variables on the page

console.log('Pos:' + lastPosStr + " " + humIn);

document.getElementById("WtrOutNum").innerHTML = wthrOut;

document.getElementById("Pressure").innerHTML = Atmpress;

document.getElementById("HumOutNum").innerHTML = humOut;

// Position of Internal Variables

posWthrIn = message.toString().search('inTemp');

posHumIn = message.toString().search('inHum');

lastPosStr = message.toString().search('}');

// Extraction of variables

wthrIn = message.toString().substring(posWthrIn+8,posHumIn-3);

humIn = message.toString().substring(posHumIn+8, lastPosStr);

// Updating the variables on the page

console.log('Pos:' + lastPosStr + " " + humIn);

document.getElementById("WtrNum").innerHTML= wthrIn;

document.getElementById("WiNum").innerHTML= humIn;

})

Figure 7 shows the measurements taken from January 14th to February 11th, 2022, with a periodicity of 10 min.

Figure 7: Dashboard: temperature and humidity of the internal environment.

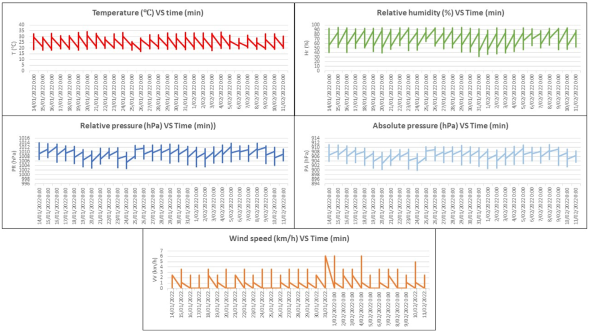

Likewise, through the PCE-FWS 20N meteorology station, the measurement, recording, and storage of the following variables was performed: temperature , ambient humidity , relative and absolute pressure , wind speed , and wind direction. Figure 8 presents the dashboard of the measurements taken.

Figure 8: Dashboard: micro-climatic variables of the PCE-FWS 20N station.

The greenhouse can be controlled in two ways: manually and on-site, using the command control box that allows to enable/disable the motor pumps or the drip irrigation solenoid valves; or through a web application that allows for the automatic control of the aforementioned devices. Manually, two motor pumps and four solenoid valves are controlled independently, thus allowing the on-site intervention of the operator. Activation/deactivation data are stored in the MySQL server database with the MQTT protocol of the IoT. Additionally, the irrigation system is controlled wirelessly through a web app developed in the HTML5 language, with instructions in PHP. This app interacts bidirectionally with the activation hardware of the motor pumps and solenoid valves.

Likewise, the server continuously records the data supplied by the greenhouse’s sensors, presenting, in the form of a dashboard, real-time information of the internal and external variables measured by the meteorological station. Figure 9 presents the interactive user interface of the web app, which can be operated from any mobile device with an Internet browser. The web address where the app is hosted is: http://www.invernaderouv.decartago.com/index.html

Figure 9: Web app for the measurement and control of the greenhouse.

Conclusions

The completion of this project entails the availability of environments protected with adaptable micro-climates for optimally growing some crops through the use of technology, leveraged according to the concept of the Industry 4.0 (IoT, Big Data), making use of low-cost devices that impact agricultural research in the region and the country. Now, there is an automated greenhouse that allows processing data in real time, with greater management of the internal temperature, which is also operated via wireless temperature and humidity sensors with a visualization console. This system includes three ZD510 capacitive humidity sensors for each planting bed, each one independently connected to an Arduino Nano board and an NFRL2401 communication board. This is complemented by the possibility of recording and storing the data resulting from the measurement processes, which can be accessed from any platform via a web app.

Thanks to IoT systems, it is now possible to store, process, and present the data obtained over time, which contributes to the advancement of the country’s the agricultural sector. Furthermore, both control modes (manual and automatic control via the web app) are reliable, which is evidenced by precision values of for temperature and for humidity, with an in the process of linearization.

Having an automated greenhouse with IoT technology framed within Agriculture 4.0 as an environment for agricultural research, as well as engaging academia, the productive agricultural sectors, the government, and other interested parties in the subject, will generate new ideas with the aim to advance and strengthen the agriculture of the region and the country by making it more competitive.

As for future projects, it worth mentioning that having an intelligent greenhouse that allows data storage is among the conditions necessary to develop predictive methods regarding harvests, i.e., through the use of Machine Learning algorithms that will allow enhancing agricultural practices and will strengthen Colombian agriculture.

In a future study, we aim to calculate the crop’s evapotranspiration and thus determine how much water the earth needs. Currently, the greenhouse has the right conditions to estimate those parameters.

Acknowledgements

Funding and Acknowledgements

This project was funded Universidad del Valle (Colombia). Special thanks to the teachers Andrés Felipe Serna Ruiz and Johana Medina for their support in the achieved technological development.

References

License

Copyright (c) 2023 Edward Marín-Garcia, José-Neftalí Torres-Marín, Alexandra Chaverra-Lasso

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

When submitting their article to the Scientific Journal, the author(s) certifies that their manuscript has not been, nor will it be, presented or published in any other scientific journal.

Within the editorial policies established for the Scientific Journal, costs are not established at any stage of the editorial process, the submission of articles, the editing, publication and subsequent downloading of the contents is free of charge, since the journal is a non-profit academic publication. profit.