DOI:

https://doi.org/10.14483/23448393.16926Publicado:

2020-10-02Número:

Vol. 25 Núm. 3 (2020): Septiembre - DiciembreSección:

Sección Especial: Mejores artículos extendidos - WEA 2020The Sustainable Supply Chain: Concepts, Optimization and Simulation Models, and Trends

La cadena de suministro sostenible: conceptos, modelos de optimizaci´on y de simulaci´on y tendencias

Palabras clave:

Desempe˜no sostenible, gesti´on de la cadena de suministro sostenible, gesti´on de la cadena de suministro verde, modelamiento, sostenibilidad triple (es).Palabras clave:

Sustainable Supply Chain Management, Green Supply Chain Management, sustainable performance, Triple Bottom Line, Modeling (en).Descargas

Referencias

B. S. Silvestre, “Sustainable supply chain management in emerging economies: Environmental turbulence, institutional voids and sustainability trajectories”, International Journal of Production Economics, vol. 167, pp. 156-169, 2015. http://dx.doi.org/10.1016/j.ijpe.2015.05.025

A. Diabat, T. Abdallah, A. Al-Refaie, D. Svetinovic, and K. Govindan, “Strategic closed-loop facility location problem with carbon market trading”, IEEE Transactions on Engineering Management, vol. 60, no. 2, pp. 398- 408, 2013. https://doi.org/10.1109/TEM.2012.2211105

S. Luthra, K. Govindan, D. Kannan, S. K. Mangla, and C. P. Garg, “An integrated framework for sustainable supplier selection and evaluation in supply chains”, Journal of Cleaner Production, vol. 140, pp. 1686-1698, 2017. http://dx.doi.org/10.1016/j.jclepro.2016.09.078

T. Rebs, M. Brandenburg, and S. Seuring, “System dynamics modeling for sustainable supply chain management: A literature review and systems thinking approach”, Journal of Cleaner Production, vol. 208, pp. 1265- 1280, 2019. https://doi.org/10.1016/j.jclepro.2018.10.100

J. Sarkis, “Supply Chain Management and Environmentally Conscious Design and Manufacturing”, International Journal of Environmentally Conscious Design and Manufacturing, vol. 4, pp. 43-52, 1995. [Online] Available; https://www.researchgate.net/publication/259261058_Supply_Chain_

Management_and_Environmentally_Conscious_Design_and_Manufacturing

S. Seuring, and M. Müller, “From a literature review to a conceptual framework for sustainable supply chain management”, Journal of Cleaner Production, vol. 16, no. 15, pp. 1699-1710, 2008. https://doi.org/10.1016/j.jclepro.2008.04.020

S. K. Srivastava, “Green supply-chain management: A state-of-the-art literature review”, International Journal of Management Reviews, vol. 9, no. 1, pp. 53-80, 2007. https://doi.org/10.1111/j.1468-2370. 2007.00202.x

J. Sarkis, Q. Zhu, and K. H. Lai, “An organizational theoretic review of green supply chain management literature”, International Journal of Production Economics, vol. 130, no. 1, pp. 1-15, 2011. http://dx.doi.org/10.1016/j.ijpe.2010.11.010

S. Seuring, “A review of modeling approaches for sustainable supply chain management”, Computers and Industrial Engineering, vol. 66, no. 3, pp. 533-540, 2013. https://doi.org/10.1016/j.dss.2012. 05.053

M. Brandenburg, K. Govindan, J. Sarkis, and S. Seuring, “Quantitative models for sustainable supply chain management: Developments and directions”, European Journal of Operational Research, vol. 233, no. 2, pp. 299-312, 2014. http://dx.doi.org/10.1016/j.ejor.2013.09.032

A. Genovese, A. A. Acquaye, A. Figueroa, and S. C. Koh, “Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications”, Omega, vol. 66, pp. 344-357, 2017. http://dx.doi.org/10.1016/j.omega.2015.05.015

D. L. Rincón Ballesteros, J. E. Fonseca Ramírez, and J. A. Orjuela-Castro, “Hacia un Marco Conceptual Común sobre Trazabilidad en la Cadena de Suministro de Alimentos”, Ingeniería, vol. 22, no. 2, pp. 161, 2017. https: //doi.org/10.14483/udistrital.jour.reving.2017.2.a01

J. A. Orjuela, “Incidencia del diseño de la cadena de suministro alimentaria en el equilibrio de flujos logísticos”, Ph.D. thesis, Universidad Nacional de Colombia, Bogotá, D.C., 2018. [Online] Available; http://bdigital.unal.edu.co/69976/

U. Nations., Report of the World Commission on Environment and Development Our Common FutureUnited Nations, 1987. [Online] Available; http://www.ask-force.org/web/Sustainability/ Brundtland-Our-Common-Future-1987-2008.pdf

S. Schrettle, A. Hinz, M. Scherrer-Rathje, and T. Friedli, “Turning sustainability into action: Explaining firms’ sustainability efforts and their impact on firm performance”, International Journal of Production Economics, vol. 147, pp. 73-84, 2014. https://doi.org/10.1016/j.ijpe.2013.02.030

B. S. Silvestre, “A hard nut to crack! Implementing supply chain sustainability in an emerging economy”, Journal of Cleaner Production, vol. 96, pp. 171-181, 2015. http://dx.doi.org/10.1016/j.jclepro.2014.01.009

A. Touboulic, D. Chicksand, and H. Walker, “Managing Imbalanced Supply Chain Relationships for Sustainability: A Power Perspective”, Decision Sciences, vol. 45, no. 4, pp. 577-619, 2014. https://doi.org/10.1111/deci.12087

N. Kafa, Y. Hani, and A. El Mhamedi, “Sustainability performance measurement for green supply chain management”, IFAC Proceedings Volumes, vol. 6, 2013. https://doi.org/10.3182/ 20130911-3-BR-3021.00050

B. Bakshi, Sustainable Engineering: Principles and Practice. Cambridge: Cambridge University Press, 2019. https://doi.org/10.1017/9781108333726

D. J. Closs, C. Speier, and N. Meacham, “Sustainability to support end-to-end value chains: The role of supply chain management”, Journal of the Academy of Marketing Science, vol. 39, no. 1, pp. 101-116, 2011. https://doi.org/10.1007/s11747-010-0207-4

J. R. Chacón, C. E. Moreno, and A. B. L. de Sousa, “Enablers of sustainable supply chain management and its effect on competitive advantage in the Colombian context”, Resources, Conservation and Recycling, vol. 139, pp. 237-250, 2018. https://doi.org/10.1016/j.resconrec.2018.08.018

S. Luthra, D. Garg, and A. Haleem, “An analysis of interactions among critical success factors to implement green supply chain management towards sustainability: An Indian perspective”, Resources Policy, vol. 46, pp. 37-50, 2015. https://doi.org/10.1016/j.resourpol.2014.12.006

P. Ahi, and C. Searcy, “An analysis of metrics used to measure performance in green and sustainable supply chains”, Journal of Cleaner Production, vol. 86, pp. 360-377, 2015. https://doi.org/10.1016/j.jclepro.2013.02.018

F. Caniato, M. Caridi, L. Crippa, and A. Moretto, “Environmental sustainability in fashion supply chains: An exploratory case based research”, International Journal of Production Economics, vol. 135, no. 2, pp. 659-670, 2012. http://dx.doi.org/10.1016/j.ijpe.2011.06.001

I. Erol, S. Sencer, and R. Sari, “A new fuzzy multi-criteria framework for measuring sustainability performance of a supply chain”, Ecological Economics, vol. 70, no. 6, pp. 1088-1100, 2011. https://doi.org/10. 1016/j.ecolecon.2011.01.001

D. R. Maditati, Z. H. Munim, H. J. Schramm, and S. Kummer, “A review of green supply chain management: From bibliometric analysis to a conceptual framework and future research directions”, Resources, Conservation and Recycling, vol. 139, pp. 150-162, 2018. https://doi.org/10.1016/j.resconrec.2018.08. 004

M. Mahdiloo, R. F. Saen, and K. H. Lee, “Technical, environmental and eco-efficiency measurement for supplier selection: An extension and application of data envelopment analysis”, International Journal of Production Economics, vol. 168, pp. 279-289, 2015. http://dx.doi.org/10.1016/j.ijpe.2015.07.010

C. R. Carter, and D. S. Rogers, “A framework of sustainable supply chain management: Moving toward new theory”, International Journal of Physical Distribution and Logistics Management, vol. 38, no. 5, pp. 360-387, 2008. https://doi.org/10.1108/09600030810882816

A. Ashby, M. Leat, and M. Hudson-Smith, “Making connections: a review of supply chain management and sustainability literature”, Supply Chain Management: An International Journal, vol. 17, no. 5, pp. 497-516, 2012. https://doi.org/10.1108/13598541211258573

S. Liu, D. Kasturiratne, and J. Moizer, “A hub-and-spoke model for multi-dimensional integration of green marketing and sustainable supply chain management”, Industrial Marketing Management, vol. 41, no. 4, pp. 581-588, 2012. http://dx.doi.org/10.1016/j.indmarman.2012.04.005

P. Ahi, and C. Searcy, “A comparative literature analysis of definitions for green and sustainable supply chain management”, Journal of Cleaner Production, vol. 52, pp. 329-341, 2013. http://dx.doi.org/10.1016/j.jclepro.2013.02.018

M. Farooque, A. Zhang, M. Thürer, T. Qu, and D. Huisingh, “Circular supply chain management: A definition and structured literature review”, Journal of Cleaner Production, vol. 228, pp. 882-900, 2019. https:// doi.org/10.1016/j.jclepro.2019.04.303

K.W. Green, P. J. Zelbst, J. Meacham, and V. S. Bhadauria, “Green supply chain management practices: Impact on performance”, Supply Chain Management, vol. 17, no. 3, pp. 290-305, 2012. https://doi.org/10.1108/13598541211227126

Q. Zhu, and J. Sarkis, “Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises”, Journal of Operations Management, vol. 22, no. 3, pp. 265-289, 2004. https://doi.org/10.1016/j.jom.2004.01.005

Q. Zhu, and J. Sarkis, “The moderating effects of institutional pressures on emergent green supply chain practices and performance”, International Journal of Production Research, vol. 45, no. 18-19, pp. 4333-4355, 2007. https://doi.org/10.1080/00207540701440345

M. Zhang, Y. K. Tse, B. Doherty, S. Li, and P. Akhtar, “Sustainable supply chain management: Confirmation of a higher-order model”, Resources, Conservation and Recycling, vol. 128, pp. 206-221, 2018. https://doi. org/10.1016/j.resconrec.2016.06.015

M. L. Tseng, A. S. F. Chiu, R. R. Tan, and A. B. Siriban-Manalang, “Sustainable consumption and production for Asia: Sustainability through green design and practice”, Journal of Cleaner Production, vol. 40, pp. 1-5, 2013. http://dx.doi.org/10.1016/j.jclepro.2012.07.015

T. K. Eltayeb, S. Zailani, and T. Ramayah, “Green supply chain initiatives among certified companies in Malaysia and environmental sustainability: Investigating the outcomes”, Resources, Conservation and Recycling, vol. 55, no. 5, pp. 495-506, 2011. http://dx.doi.org/10.1016/j.resconrec.2010.09. 003

G. Kannan, S. Azevedo, H. Carvalho, and V. Cruz-Machado, “Impact of supply chain management practices on sustainability”, Journal of Cleaner Production, vol. 85, pp. 212-225, 2014. http://dx.doi.org/10.1016/j.jclepro.2014.05.068

S. G. Azevedo, H. Carvalho, S. Duarte, and V. Cruz-Machado, “Influence of Green and Lean Upstream Supply Chain Management Practices on Business Sustainability”, IEEE Transactions on Engineering Management, vol. 59, no. 4, pp. 753-765, 2012. http://ieeexplore.ieee.org/document/6179327/

P. Y. Foo, V. H. Lee, G. W. H. Tan, and K. B. Ooi, “A gateway to realising sustainability performance via green supply chain management practices: A PLS-ANN approach”, Expert Systems with Applications, vol. 107, pp. 1-14, 2018. https://doi.org/10.1016/j.eswa.2018.04.013

N. Darnall, G. J. Jolley, and R. Handfield, “Environmental management systems and green supply chain management: Complements for sustainability?”, Business Strategy and the Environment, vol. 17, no. 1, pp. 30-45, 2008. https://doi.org/10.1002/bse.557

S. Vachon, and R. D. Klassen, “Extending green practices across the supply chain: The impact of upstream and downstream integration”, International Journal of Operations and Production Management, vol. 26, no. 7, pp. 795-821, 2006. https://doi.org/10.1108/01443570610672248

M. A. Rehman, D. Seth, and R. Shrivastava, “Impact of green manufacturing practices on organisational performance in Indian context: An empirical study”, Journal of Cleaner Production, vol. 137, pp. 427-448, 2016. https://doi.org/10.1016/j.jclepro.2016.07.106

C. Blome, A. Paulraj, and K. Schuetz, “Supply chain collaboration and sustainability: A profile deviation analysis”, International Journal of Operations and Production Management, vol. 34, no. 5, pp. 639-663, 2014. https://doi.org/10.1108/IJOPM-11-2012-0515

V. Mani, R. Agarwal, A. Gunasekaran, T. Papadopoulos, R. Dubey, and S. J. Childe, “Social sustainability in the supply chain: Construct development and measurement validation”, Ecological Indicators, vol. 71, pp. 270-279, 2016. http://dx.doi.org/10.1016/j.ecolind.2016.07.007

V. Mani, A. Gunasekaran, and C. Delgado, “Enhancing supply chain performance through supplier social sustainability: An emerging economy perspective”, International Journal of Production Economics, vol. 195, pp. 259-272, 2018. https://doi.org/10.1016/j.ijpe.2017.10.025

C. Leire, and O. Mont, “The implementation of socially responsible purchasing”, Corporate Social Responsibil ity and Environmental Management, vol. 17, no. 1, pp. 27-39, 2010. https://doi.org/10.1002/csr.198

P. Ahi, C. Searcy, and M. Y. Jaber, “Energy-related performance measures employed in sustainable supply chains: A bibliometric analysis”, Sustainable Production and Consumption, vol. 7, pp. 1-15, 2016. http: //dx.doi.org/10.1016/j.spc.2016.02.001

F. T. Chan, and A. Prakash, “Inventory management in a lateral collaborative manufacturing supply chain: A simulation study”, International Journal of Production Research, vol. 50, no. 16, pp. 4670-4685, 2012. https://doi.org/10.1080/00207543.2011.628709

H. Allaoui, Y. Guo, and J. Sarkis, “Decision support for collaboration planning in sustainable supply chains”, Journal of Cleaner Production, vol. 229, pp. 761-774, 2019. https://doi.org/10.1016/j.jclepro.2019.04.367

J. A. Orjuela-Castro, A. L. Caicedo-Otavo, A. F. Ruiz-Moreno, and W. Adarme-Jaimes, “External integration mechanisms effect on the logistics performance of fruit supply chains. A dynamic system approach”, Revista Colombiana de Ciencias Hortícolas, vol. 10, no. 2, pp. 311-322, 2016. https://doi.org/10.17584/rcch.2016v10i2.5073

M. Hudnurkar, and U. Rathod, “Collaborative supply chain: Insights from simulation”, International Journal of Systems Assurance Engineering and Management, vol. 3, no. 2, pp. 122-144, 2012. https://doi.org/10.1007/s13198-012-0114-9

M. Cao, M. A. Vonderembse, Q. Zhang, and T. Ragu-Nathan, “Supply chain collaboration: conceptualisation and instrument development”, International Journal of Production Research, vol. 48, no. 22, pp. 6613-6635, 2010. https://www.tandfonline.com/doi/full/10.1080/00207540903349039

L. Chen, X. Zhao, O. Tang, L. Price, S. Zhang, and W. Zhu, “Supply chain collaboration for sustainability: A literature review and future research agenda”, International Journal of Production Economics, vol. 194, pp. 73-87, 2017. https://doi.org/10.1016/j.ijpe.2017.04.005

S. Laari, J. Töyli, and L. Ojala, “Supply chain perspective on competitive strategies and green supply chain management strategies”, Journal of Cleaner Production, vol. 141, pp. 1303-1315, 2017. https://doi.org/10.1016/j.jclepro.2016.09.114

Z. N. Ansari, and R. Kant, “A state-of-art literature review reflecting 15 years of focus on sustainable supply chain management”, Journal of Cleaner Production, vol. 142, pp. 2524-2543, 2017. https://doi.org/10.1016/j.jclepro.2016.11.023

M. Brandenburg, and T. Rebs, “Sustainable supply chain management: A modelling perspective”, Annals of Operations Research, vol. 229, no. 1, pp. 213-252, 2015. http://dx.doi.org/10.1007/s10479-015-1853-1

K. Vasileiou, and J. Morris, “The sustainability of the supply chain for fresh potatoes in Britain”, Supply Chain Management, vol. 11, no. 4, pp. 317-327, 2006. https://doi.org/10.1108/13598540610671761

S. Sim, M. Barry, R. Clift, and S. J. Cowell, “The relative importance of transport in determining an appropriate sustainability strategy for food sourcing. A case study of fresh produce supply chains”, International Journal of Life Cycle Assessment, vol. 12, no. 6, pp. 422-431, 2007. https://doi.org/10.1065/lca2006.07.259

J. Hamprecht, D. Corsten, M. Noll, and E. Meier, “Controlling the sustainability of food supply chains”, Supply Chain Management, vol. 10, no. 1, pp. 7-10, 2005. https://doi.org/10.1108/ 13598540510578315

R. K. Apaiah, A. R. Linnemann, and H. J. Van Der Kooi, “Exergy analysis: A tool to study the sustainability of food supply chains”, Food Research International, vol. 39, no. 1, pp. 1-11, 2006. https://doi.org/10.1016/j.foodres.2005.04.006

P. Newton, A. Agrawal, and L. Wollenberg, “Enhancing the sustainability of commodity supply chains in tropical forest and agricultural landscapes”, Global Environmental Change, vol. 23, no. 6, pp. 1761-1772, 2013. http://dx.doi.org/10.1016/j.gloenvcha.2013.08.004

A. Del Borghi, M. Gallo, C. Strazza, and M. Del Borghi, “An evaluation of environmental sustainability in the food industry through Life Cycle Assessment: The case study of tomato products supply chain”, Journal of Cleaner Production, vol. 78, pp. 121-130, 2014. http://dx.doi.org/10.1016/j.jclepro.2014.04.083

G. Egilmez, M. Kucukvar, O. Tatari, and M. K. S. Bhutta, “Supply chain sustainability assessment of the U.S. food manufacturing sectors: A life cycle-based frontier approach”, Resources, Conservation and Recycling, vol. 82, pp. 8-20, 2014. http://dx.doi.org/10.1016/j.resconrec.2013.10.008

J. G. Van Der Vorst, S. O. Tromp, and D. J. Van Der Zee, “Simulation modelling for food supply chain redesign; Integrated decision making on product quality, sustainability and logistics”, International Journal of Production Research, vol. 47, no. 23, pp. 6611-6631, 2009. https://doi.org/10.1080/00207540802356747

J. A. Orjuela, I. Huertas, J. Figueroa, D. Kalenatic, and K. Kadena, “Potential production bioethanol from the Panela Cane: dynamics between pollution, food safety and land use”, Ingeniería, , no. 1, pp. 6-26. https://doi.org/10.14483/23448393.3689

I. Awudu, and J. Zhang, “Uncertainties and sustainability concepts in biofuel supply chain management: A review”, Renewable and Sustainable Energy Reviews, vol. 16, no. 2, pp. 1359-1368, 2012. http://dx.doi.org/10.1016/j.rser.2011.10.016

J. A. Aranda, M. J. Barón, I. Huertas, and J. A. Orjuela, “Mathematical Programming Model of Biodiesel Supply Chain in Colombia”, Ingeniería, vol. 19, no. 1, pp. 19-49, 2014. https://doi.org/10.14483/udistrital.jour.reving.2014.1.a02

J. A. Aranda, and J. A. Orjuela, “Multiobjective optimization in biofuel supply chain management. A review of the literature”, Ingeniería, vol. 20, no. 1, pp. 2-3, 2015. https://doi.org/10.14483/udistrital.jour.reving.2015.1.a03

T. M. Mata, A. A. Martins, S. K. Sikdar, and C. A. Costa, “Sustainability considerations of biodiesel based on supply chain analysis”, Clean Technologies and Environmental Policy, vol. 13, no. 5, pp. 655-671, 2011. https://doi.org/10.1007/s10098-010-0346-9

R. Mahmoudi, and M. Rasti-Barzoki, “Sustainable supply chains under government intervention with a realworld case study: An evolutionary game theoretic approach”, Computers and Industrial Engineering, vol. 116, pp. 130-143, 2018. https://doi.org/10.1016/j.cie.2017.12.028

P. Georgiadis, and M. Besiou, “Sustainability in electrical and electronic equipment closed-loop supply chains: A System Dynamics approach”, Journal of Cleaner Production, vol. 16, no. 15, pp. 1665-1678, 2008. https://doi.org/10.1016/j.jclepro.2008.04.019

P. Georgiadis, and M. Besiou, “Environmental and economical sustainability of WEEE closed-loop supply chains with recycling: A system dynamics analysis”, International Journal of Advanced Manufacturing Technology, vol. 47, pp. 475-493, 2010. https://doi.org/10.1007/s00170-009-2362-7

K. Govindan, A. Jafarian, and V. Nourbakhsh, “Bi-objective integrating sustainable order allocation and sustainable supply chain network strategic design with stochastic demand using a novel robust hybrid multi-objective metaheuristic”, Computers and Operations Research, vol. 62, pp. 112-130, 2015. http://dx.doi.org/10.1016/j.cor.2014.12.014

S. Validi, A. Bhattacharya, and P. J. Byrne, “A solution method for a two-layer sustainable supply chain distribution model”, Computers and Operations Research, vol. 54, pp. 204-217, 2015. http://dx.doi.org/10.1016/j.cor.2014.06.015

S. Validi, A. Bhattacharya, and P. J. Byrne, “A case analysis of a sustainable food supply chain distribution system - A multi-objective approach”, International Journal of Production Economics, vol. 152, pp. 71-87, 2014. http://dx.doi.org/10.1016/j.ijpe.2014.02.003

F. You, L. Tao, D. J. Graziano, and S.W. Snyder, “Optimal design of sustainable cellulosic biofuel supply chains: Multiobjective optimization coupled with life cycle assessment and input-output analysis”, AIChE Journal, vol. 58, no. 4, pp. 1157-1180, 2012. https://doi.org/10.1002/aic.12637

G. Guillén-Gosálbez, and I. E. Grossmann, “Optimal design and planning of sustainable chemical supply chains under uncertainty”, AIChE Journal, vol. 55, no. 1, pp. 99-121, 2009. https://doi.org/10.1002/aic.11662

D. Yue, M. Kim, and F. You, “Design of Sustainable Product Systems and Supply Chains with Life Cycle Optimization based on Functional Unit: General Modeling Framework, MINLP Algorithms”, ACS Sustainable Chemistry and Engineering, vol. 1, pp. 1003-1014, 2013. https://doi.org/10.1021/sc400080x

K. Govindan, A. Jafarian, R. Khodaverdi, and K. Devika, “Two-echelon multiple-vehicle location-routing problem with time windows for optimization of sustainable supply chain network of perishable food”, International Journal of Production Economics, vol. 152, pp. 9-28, 2014. http://dx.doi.org/10.1016/j.ijpe.2013.12.028

S. K. Jakhar, “Performance evaluation and a flow allocation decision model for a sustainable supply chain of an apparel industry”, Journal of Cleaner Production, vol. 87, no. 1, pp. 391-413, 2015. http://dx.doi.org/10.1016/j.jclepro.2014.09.089

H. Soleimani, K. Govindan, H. Saghafi, and H. Jafari, “Fuzzy multi-objective sustainable and green closed-loop supply chain network design”, Computers and Industrial Engineering, vol. 109, pp. 191-203, 2017. http://dx.doi.org/10.1016/j.cie.2017.04.038

G. Corsano, A. R. Vecchietti, and J. M. Montagna, “Optimal design for sustainable bioethanol supply chain considering detailed plant performance model”, Computers and Chemical Engineering, vol. 35, no. 8, pp. 1384-1398, 2011. http://dx.doi.org/10.1016/j.compchemeng.2011.01.008

M. Azadi, M. Jafarian, R. F. Saen, and S. M. Mirhedayatian, “A new fuzzy DEA model for evaluation of efficiency and effectiveness of suppliers in sustainable supply chain management context”, Computers and Operations Research, vol. 54, pp. 274-285, 2015. http://dx.doi.org/10.1016/j.cor.2014.03. 002

J. A. Orjuela-Castro, J. A. Aranda-Pinilla, and C. E. Moreno-Mantilla, “Identifying trade-offs between sustainability dimensions in the supply chain of biodiesel in Colombia”, Computers and Electronics in Agriculture, vol. 161, pp. 162-169, 2019. https://doi.org/10.1016/j.compag.2018.03.009

G. Büyüközkan, and Ç. Berkol, “Designing a sustainable supply chain using an integrated analytic network process and goal programming approach in quality function deployment”, Expert Systems with Applications, vol. 38, no. 11, pp. 13731-13748, 2011. https://doi.org/10.1016/j.eswa.2011.04.171

N. Sahay, and M. Ierapetritou, “Supply chain management using an optimization driven simulation approach”, AIChE Journal, vol. 59, no. 12, pp. 4612-4626, 2013. http://doi.wiley.com/10.1002/aic.14226

Z. Tao, and M. Li, “What is the limit of Chinese coal supplies-A STELLA model of Hubbert Peak”, Energy Policy, vol. 35, no. 6, pp. 3145-3154, 2007. https://doi.org/10.1016/j.enpol.2006.11.011

X. Y. Huang, N. N. Yan, and R. Z. Qiu, “Dynamic models of closed-loop supply chain and robust H1 control strategies”, International Journal of Production Research, vol. 47, no. 9, pp. 2279-2300, 2009. https://doi.org/10.1080/00207540701636355

I. J. Orji, and S. Wei, “An innovative integration of fuzzy-logic and systems dynamics in sustainable supplier selection: A case on manufacturing industry”, Computers and Industrial Engineering, vol. 88, pp. 1-12, 2015. http://dx.doi.org/10.1016/j.cie.2015.06.019

S. R. Golroudbary, and S. M. Zahraee, “System dynamics model for optimizing the recycling and collection of waste material in a closed-loop supply chain”, Simulation Modelling Practice and Theory, vol. 53, pp. 88-102, 2015. http://dx.doi.org/10.1016/j.simpat.2015.02.001

J. W. Eising, T. van Onna, and F. Alkemade, “Towards smart grids: Identifying the risks that arise from the integration of energy and transport supply chains”, Applied Energy, vol. 123, no. 2014, pp. 448-455, 2014. http://dx.doi.org/10.1016/j.apenergy.2013.12.017

A. Kumar, and S. Rahman, “RFID-enabled process reengineering of closed-loop supply chains in the healthcare industry of Singapore”, Journal of Cleaner Production, vol. 85, pp. 382-394, 2014. http://dx.doi.org/10.1016/j.jclepro.2014.04.037

S. K. Mangla, P. Kumar, and M. K. Barua, “Monte Carlo simulation based approach to manage risks in operational networks in green supply chain”, Procedia Engineering, vol. 97, pp. 2186-2194, 2014. http://dx.doi.org/10.1016/j.proeng.2014.12.462

F. Longo, “Sustainable supply chain design: An application example in local business retail”, Simulation, vol. 88, no. 12, pp. 1484-1498, 2012. https://doi.org/10.1177/0037549712458983

M. Eskandarpour, P. Dejax, J. Miemczyk, and O. Péton, “Sustainable supply chain network design: An optimization-oriented review”, Omega, vol. 54, pp. 11-32, 2015. http://dx.doi.org/10.1016/j.omega.2015.01.006

V. Mani, and A. Gunasekaran, “Four forces of supply chain social sustainability adoption in emerging economies”, International Journal of Production Economics, vol. 199, pp. 150-161, 2018. https://doi.org/10.1016/j.ijpe.2018.02.015

Y. Kalmykova, M. Sadagopan, and L. Rosado, “Circular economy - From review of theories and practices to development of implementation tools”, Resources, Conservation and Recycling, vol. 135, pp. 190-201, 2018. https://doi.org/10.1016/j.resconrec.2017.10.034

M. A. Moktadir, T. Rahman, M. H. Rahman, S. M. Ali, and S. K. Paul, “Drivers to sustainable manufacturing practices and circular economy: A perspective of leather industries in Bangladesh”, Journal of Cleaner Production, vol. 174, pp. 1366-1380, 2018. https://doi.org/10.1016/j.jclepro.2017.11.063

M. H. A. Nasir, A. Genovese, A. A. Acquaye, S. C. Koh, and F. Yamoah, “Comparing linear and circular supply chains: A case study from the construction industry”, International Journal of Production Economics, vol. 183, pp. 443-457, 2017. http://dx.doi.org/10.1016/j.ijpe.2016.06.008

R. Sharma, C. J. C. Jabbour, and A. B. Lopes de Sousa Jabbour, “Sustainable manufacturing and industry 4.0: what we know and what we don’t”, Journal of Enterprise Information Management. https://doi.org/10.1108/JEIM-01-2020-0024

M. S. Pishvaee, J. Razmi, and S. A. Torabi, “An accelerated Benders decomposition algorithm for sustainable supply chain network design under uncertainty: A case study of medical needle and syringe supply chain”, Transportation Research, vol. 67, pp. 14-38, 2014. http://dx.doi.org/10.1016/j.tre.2014.04.001

S. J. Childe, S. F. Wamba, A. Gunasekaran, R. Dubey, K. Shibin, and T. Papadopoulos, “Sustainable supply chain management: framework and further research directions”, Journal of Cleaner Production, vol. 142, pp. 1119-1130, 2016. http://dx.doi.org/10.1016/j.jclepro.2016.03.117

Cómo citar

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Descargar cita

Recibido: 1 de junio de 2020; Revisión recibida: 31 de agosto de 2020; Aceptado: 15 de septiembre de 2020

Abstract

Context:

The environmental and social dimensions of performance are of great importance, given that they must be incorporated into strategic, tactical, and operational objectives in companies and supply chains to minimize negative impacts on the environment and society.

Method:

After reviewing the Scopus, Web of Science, and ScienceDirect databases for the topics of sustainability and supply chain management, a state of the art of green and sustainable supply chain management is presented, aiming to guide readers towards a synthesis of related concepts and future lines of research.

Results:

The reader is introduced to concepts and trends around the field of green and sustainable supply chain management to raise interest in new research and practices to guide the implementation of sustainability in organizations and their supply chains.

Conclusions:

Sustainable supply chain management still faces several academic and practical challenges in terms of implementation, performance measurement, and how models can capture a dynamic and uncertain social and environmental context. There are latent research issues such as management of the circular supply chain, applications in emerging economies, or the application of 4.0 technologies.

Keywords:

Green supply chain management, modeling, sustainable performance, sustainable supply chain management, triple bottom line.Resumen

Contexto:

Las dimensiones ambiental y social del desempeño son de gran importancia, puesto que deben ser incorporadas a los objetivos estratégicos, tácticos y operativos de las empresas y cadenas de suministro para minimizar los impactos negativos sobre el medio ambiente y la sociedad.

Método:

Tras haber consultado los temas de sostenibilidad y gestión de la cadena de suministro en las bases de datos Scopus, Web of Science y ScienceDirect, se presenta el estado del arte en gestión de la cadena de suministro verde y sostenible, esperando guiar a los lectores hacia una síntesis de conceptos relacionados y futuras líneas de investigación.

Resultados:

Se introduce al lector a conceptos y tendencias en el campo de gestión de la cadena de suministro verde y sostenible para despertar el interés en nuevas investigaciones y prácticas para guiar la implementación de la sostenibilidad en organizaciones y sus cadenas de suministro.

Conclusiones:

La gestión sostenible de la cadena de suministro aún enfrenta varios retos académicos y prácticos, desafíos en términos de implementación, medición del desempeño y la manera en que los modelos pueden capturar un contexto social y ambiental dinámico e incierto. Hay cuestiones de investigación latentes como la gestión de la cadena de suministro circular, las aplicaciones en economías emergentes o la aplicación de tecnologías 4.0.

Palabras clave:

Desempeño sostenible, gestión de la cadena de suministro sostenible, gestión de la cadena de suministro verde, modelamiento, sostenibilidad triple..Introduction

Supply chain management (SCM) has acquired relevance in a global corporate and competitive environment [1]. Academia, industry, and government have looked for ways of jointly improving economic performance and systems sustainability [2]. One way of seeing this is that environmental and social issues are linked to industrial processes carried out in supply chains (SC). The challenge is to implement alternatives to the activities in SC, fostering significant changes in the economic, environmental, and social dimensions, thus allowing success in long-term development of SCs [3]. Hence, SCs are perceived as elements of economic systems embedded in social systems, which in turn, depend on ecological systems [4]. Consequently, it is necessary to make decisions considering sustainability as an important factor.

This article aims to guide readers through topics and current perspectives on Green Supply Chain Management (GSCM) and Sustainable Supply Chain Management (SSCM), given the emerging importance of these fields, with the purpose of motivating future research and applications on SC. We intend to achieve these objectives by addressing the following research questions: How is sustainability understood in supply chains? What concepts are related to it? What factors or motivations lead to opting for a sustainable supply chain (SSC)? Which optimization and simulation models have been used to model SSCs? What are the current trends that guide research in SSCM? We expect to contribute to the SSCM field by bringing a conceptual basis for researchers who wish to embrace sustainability in SCs.

This article is supported by previous reviews and arguments in the literature. [5] was one of the first to tackle SCM from an ecological perspective, based on customer-supplier relationships and links to the internal dimensions of the organization. Later, [6] presented a conceptual SSCM framework focused on supplier management and SCM for sustainable products, highlighting the ecological and environmental issues as dominant within literature. As for the GSC, [7] made a review on the state of art, providing an integrative view on GSCM as a field of research. [8] reviewed the literature under several organizational theories with emphasis on GSCM practices. Similarly, [9] addressed more than 300 articles from 15 previous years about GSC and SSC, finding that 36 of them applied quantitative models, thus presenting research opportunities in 2013. In the same way, a year later, [10] presented a research on the application of formal models with social or environmental factors in SCs, including analytic models and lifecycle assessment. In the same field, circular economy started to gain relevance; [11] emphasized that not only should there be viable relationships between ecological systems and economic growth, but self-sustaining systems should also be created, comparing traditional systems with circular systems. In parallel, [4] presented, at the beginning of 2019, a review on modeling systems dynamics, where the quantitative model in the SSCM was highlighted and proposed a systemic approach to analyze complex and dynamic SCs.

To achieve the objective of the research, this article is organized as follows: the concepts found in the literature on supply chains and sustainability, GSCM, and SSCM are presented first; the article continues with the results found from applications via optimization modeling and simulation, followed by trends for future research; and it ends with a synthesis of the results and the conclusions of this review.

Materials and methods

To guide the literature review, this article is based on the methodology proposed by [12]. Such methodology consists of the following phases:

Fig 1: Methodology for literature reviews by Rincón-Ballesteros [12]

In the data sources and search strategy stage, two search formulas were used. Firstly, using “green”, “social”, “sustainability” AND “supply chain” on Scopus and ScienceDirect, 731 articles were found. This search was filtered according to the title, abstract, and keywords of papers within a timeframe from 2000 to 2020. It is worth noting that 22% of the articles were published in 2019.

The research journals with highest frequency of publication were: Journal of Cleaner Production, International Journal of Production Economics, Resources, Conservation and Recycling, and Computers & Industrial Engineering. The authors with more publications were Joseph Sarkis, Kannan Govindan, Behnam Fahimnia, K.W. Green, and Sachin K. Mangla.

Secondly, a search was queried on the Web of Science database with the equation “sustainable supply chain” AND “model” OR “simulation” for the title, abstract, and keywords, where 443 documents were found within a timeframe from 1997 to 2020. The research journals with more publication frequency were: Environmental Sciences, Green Sustainable Science Technology, Operations Research Management Science, Environmental Engineering, and Industrial Engineering.

During the review and criteria selection, the articles with the highest number of citations and relevance from each database were picked and analyzed first, so duplicates could be discarded. Finally, a review was made in terms of keywords, and the articles were classified into four categories: conceptual, review, mathematical model, or simulation. Around 120 articles were reviewed, and 89 were chosen for this article.

For the data extraction stage, the conceptual articles were analyzed considering their contributions, keywords, definitions, and conclusions. On the other hand, those articles related to modeling approaches were classified according to the information they presented: model type, objective, solution method, simulation paradigm, variables, parameters, links in the chain considered, and approach based on the pillars of sustainability. The tables containing these taxonomies can be reviewed in the appendixes.

The section pertaining to the last stage of this research, data synthesis and report, presents a synthesis of the results and an analysis of the SSC and GSC modeling articles. It also shows a synthesis graph that presents concepts and trends related to SCCM.

Results

From the literature review, a conceptualization was then derived to understand and encompass sustainability and supply chain issues.

Towards a conceptual construction

J. A. Orjuela stated in his PhD thesis [ [13], p. 28] that a SC:

is composed by a series of suppliers, producers, manufacturers, traders and consumers, as well as by the integration of its provisioning, manufacturing, storing and distribution processes, and it involves abilities management for the on-time delivery of the products to the customers and consumers and also the usage of the technology needed to accomplish a continuous information exchange. The SC challenge is to deliver the right product to the right customer at the right time. Competitive pressure and global markets forced the companies to develop SC and thus, to give an answer to the client needs quickly, which creates more complexity.

The most widely used definition of ‘sustainability’ is the one given in 1987 by the World Commission on Environment and Development [14] as meeting the needs of the present generation without compromising the ability of future generations to meet theirs. In 1994, Elkington proposed the Triple Bottom Line (TBL), where he refers to organizational performance as the management of not only the economic capital, but also of the environmental and social capitals [1], [15] - [17]. [18] describe the three dimensions:

Environmental dimension: it has evolved from concerns about emissions from the source, dumping, and environmental waste, to later focus on the local environment considering the entire life cycle of the product. It currently focuses on the capacity of ecosystems to continue providing goods and services [19]

Social dimension: it includes corporate social responsibility, which involves ethical decision making in fields such as relationships with employees, community participation, and business management practices through education and talent development [20]. Other authors include practices such as health and security management systems, as well as the design of products and processes which positively impact the consumers and workers’ well-being. This also includes actions that contribute to the welfare of the community in which the SC operates [21].

Economic dimension: it consists of the total value improvement and cost reduction of the SC from a business management perspective, as well as of strategic and sustainable initiatives that push the company’s finances and marketing forward.

[1] states that SCs must adopt and prioritize sustainability while describing how sustainable supply chains can be implemented and managed. Furthermore, [17] argue that organizational sustainability initiatives are related to the evolution of business strategies in order to address social impacts.

The most cited definition for GSCM is given by[17],p. 54, who denotes it as “integrating environmental thinking into supply-chain management (SCM),including product design, material sourcing and selection, manufacturing processes, delivery of the final product to the consumers as well as end-of-life management of the product after its useful life”. This definition was mentioned in [22] - [24].

For [ [6], p. 1700], SSCM is defined it as “the management of material, information and capital flows as well as cooperation among companies along the SC while taking goals from all three dimensions of sustainable development, i.e., economic, environmental and social, into account which are derived from customer and stakeholder requirements”. This definition was retrieved from [23], [25] - [27].

For [ [28], p. 368], SSCM is “the strategic, transparent integration and achievement of an organization’s social, environmental, and economic goals in the systemic coordination of key interorganizational business processes for improving the long-term economic performance of the individual company and its SCs”. This definition was mentioned in [17], [29], [30].

[ [31], p. 339] used a total of 22 definitions for GSCM and 12 definitions for SSCM. It was defined as follows:

“The creation of coordinated supply chains through the voluntary integration of economic, environmental, and social considerations with key inter-organizational business systems designed to efficiently and effectively manage the material, information, and capital flows associated with the procurement, production, and distribution of products or services in order to meet stakeholder requirements and improve the profitability, competitiveness, and resilience of the organization over the short and long-term.”

Circular economy has become of great importance and has incorporated the concept of circular supply chain (CSC). [ [32] p. 884] defines CSCM as:

“the integration of circular thinking into the management of the supply chain and its surrounding industrial and natural ecosystems. It systematically restores technical materials and regenerates biological materials toward a zero-waste vision through systemwide innovation in business models and supply chain functions from product/service design to end-of-life and waste management, involving all stakeholders in a product/service.”

Management practices related to GSCM and SSCM

There are social and environmental practices of GSCM and SSCM. The former can be divided into two organizational categories: intra-organizational, which includes green manufacturing, green design, and internal environmental management; and inter-organizational, which includes green purchasing, collaboration with customers, inverse logistics, and investment recovery [33] - [36]. Each of these practices is described below:

-

Green design/ eco-design: it is the implementation of prevention strategies and source-oriented approaches on the product. It includes a reduction in the use of materials, more durability, combinations between production services, software updates, and manufacturing abilities [37], as well as minimizing the environmental footprint of several products in their lifecycle [38].

-

Green purchasing: it is the conscious purchasing activity of materials and supplies that ensure the achievement of any established environmental goals [18].

-

Reverse logistics: they are the process of planification, implementation, efficient flow control, use of affordable raw materials, in-process inventory, finished products, and information from the consumption point down to the origin point, aiming to regain the product’s value at the end of its lifecycle for [39] its proper disposal or reuse, recycling, and remanufacturing [18], [40]. A topic related with the concept of reverse logistics is Investment Recovery. It implies to recover, display, and resell of surplus products, different materials (including scrap), and capital equipment when they are inactive and redundant [41].

-

ISO 14000/environmental management: this label indicates that the company has implemented a management system that documents the aspects and effects of contamination resulting from the company’s activities, as well as identifying a process to prevent contamination and continuously improving with time [42].

-

Collaboration with customers and suppliers: [41] stated that having a proximity with partners from the upstream and downstream SC, such as suppliers or customers, will facilitate an improvement in environmental performance. Several authors have researched the selection of ‘green’ suppliers. Their integration with the main suppliers and customers has been positively related to environmental collaboration [43].

-

Green manufacturing: it can be defined as manufacturing practices which do not damage the environment during any of their stages [7]. It implies applying ‘green’ or ecological product design, the use of raw materials and their containers, and the distribution and reuse of the product at the end of its lifecycle. It diminishes the depletion of natural resources and reduces waste [44], [45].

When it comes to the social dimension, the difficulties in evaluating and defining it are recognized in literature [9], since it depends on the context and tends to change, in addition to the complexity of its measurement and quantification. [21] suggest the following concepts to cover this dimension of SCs:

-

Labour practices: it includes equity, philanthropy, security, health and well-being, ethics, and human rights [46].

-

Product responsibility: in 2000, the Global Reporting Initiative (GRI) defined practices such as health and security of customers, labeling of products and services, marketing communications, customer privacy, and regulatory compliance (21).

-

Community relationships: it includes local actions such as purchasing from and developing local suppliers; helping with the construction of schools, educative centers for young people in order to generate employment, community centers, and drinking water facilities for the communities [47].

-

Socially responsible purchasing: it is considering the positive consequences of organizational purchases or generating a positive social change through purchasing behavior [48].

SC performance measures

The metric and environmental indicators for sustainable development in SCs are focused on the measurement of recycled materials, product waste, water contamination, CO2 emissions, chemical substances, water and energy consumption, renewable energy, and environmental certifications [24]. [23] identified the most frequent indicators for GSCM and SSCM present in the literature: product characteristics, quality, recycling, solid waste, flexibility, environmental management systems, customers satisfaction, carbon footprint, lifecycle assessment, profitability, cost, consumption and use of energy, energetic efficiency, environmental costs, share of the market, reduction of air emissions, and greenhouse gas [18], [49].

The following indicators related to the economic and environmental dimensions have been defined: 1) atmospheric emissions; 2) solid waste; 3) consumption of dangerous and toxic materials; 4) inventory levels; 5) product quality; 6) capacity use; 7) operational costs; and 8) training costs [40]. From the social perspective: employee motivation, level of effort to raise the consumer’s awareness about sustainability, customer and employee satisfaction, and number of conferences or exhibitions about sustainable development [18].

SC collaboration

[ [50], p. 4673] define collaboration as “a relational system in which two or more interested parties group the resources to accomplish objectives that none of them could accomplish individually”. The Handbook on the Sustainable Supply Chain (2019), chapter 6 presents the importance of collaboration and coordination between SC stakeholders, in order to achieve the objectives in terms of sustainability and accomplish effective product recycling policies.

[51] states that the most frequently used forms of collaboration contracts, information exchange, information technologies, and simultaneous decision-making. [52] evaluate logistic performance with the dynamic approach of systems when analyzing external integration mechanisms: contracts, vendor manage inventory (VMI), collaborative planning, collaborative planning forecasting and replenishment (CPFR), and information exchange.

Collaboration involves a joint and interactive process that results in activities and decisions emphasized the formalization of relationships [53]. In this way, companies aim to a competitive advantage through SC collaboration, and make the best from of the suppliers and customers resources and knowledge. This coordinates and integrates SC products and information flow [54]. [55] conclude that there is a growing group of researchers that is investigating the relationships between collaboration and sustainability, as well as the performance of the company in terms of economic, environmental, and social indicators.

GSCM and SSCM drivers

Due to the strategic pressures and motivations from various interested parties, companies are adopting GSCM in order to extend the environmental sustainability objectives to their suppliers [56], as well as to every person involved in the SC. The proper functioning of an SSC requires collaboration between its members [16], [26]. Applying sustainable business strategies worldwide can increase benefits through important gains in operational efficiency by reducing waste and global costs. This improves communities through an agreement on acceptable work conditions and compliance with regulations. It minimizes dependence on scarce environmental resources (water and raw materials) by guaranteeing long-term viability [20]. [56] claim that environmental sustainability can be used to differentiate the product and thus increase the value of the product.

[15] define exogenous and endogenous motivators for the SSCs. Among the former, we find environmental regulation, values and social norms, and market drivers. Strategy, culture, and resource base are, in turn, defined as endogenous motivators. Three topics were identified within the manufacturing firms which sum up the sustainability efforts: new manufacturing technology and more sustainable processes; the development of ecological products; and the integration of best green practices. For their part, (30) mention the following as internal motivators: improving the capacities of the company’s SSC to match with green clients; managing expectations and demand to achieve best business performance; and engaging green customers over competitors. As external motivators, government regulations, green clients demand, and community expectations are defined.

[22] identified the three main critical factors in the analysis for the implementation of GSCM: improved brand image, competitiveness of the company and economic benefits.

GSC and SSC modeling

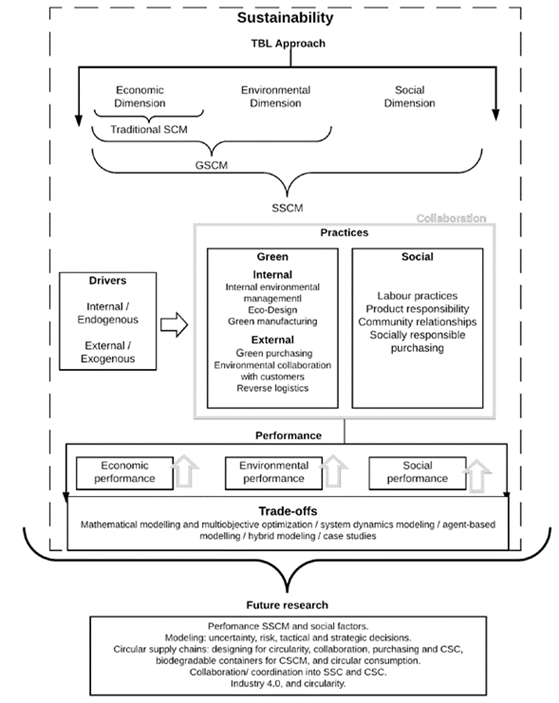

[10] carry out a review on the GSSC quantitative model and classify them into 5 types: mathematical programming methods, simulation methods, heuristic methods, hybrid methods, and analytic models. In this article, an analysis is carried out on mathematical programming models and simulations.

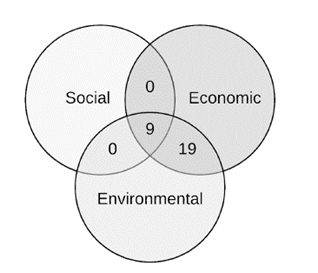

[57] found that the main areas of publication are manufacturing, food, and electronics industry. Similarly, [58] reviewed the literature related to modeling and found that energy, electronics, and agriculture are the most referenced fields. Applications are found in different sectors: food SC [59] - [66] biofuel SC [67] - [71], fashion SC [24], [72], waste electrical and electronic equipment CS [73], [74].

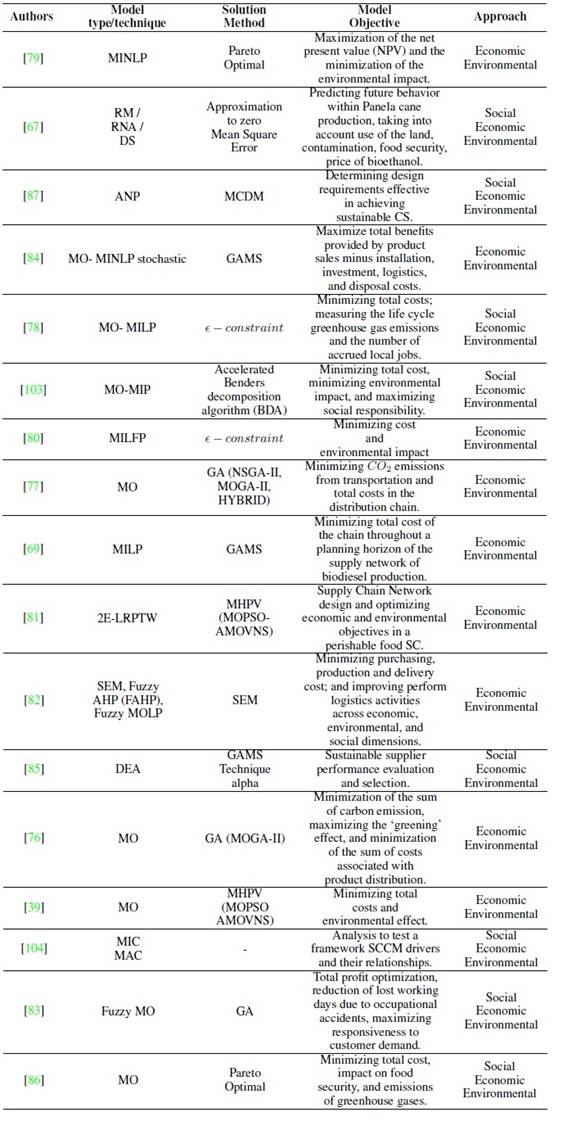

In the field of mathematical programming, mathematical multi-objective programming models stand out by aiming to minimize the total costs and carbon emission [75] - [77], linear models [69], [78], non-linear [79], fractional [80], routing [81].To have a better approach to reality, modeling a series of fuzzy [82], [83], and stochastic variables have been included [84]. Related to their functions and objectives with social factors, we found models that maximize the number of employees [78], evaluate suppliers [85], reduce workdays lost due to work accidents [83], and maximize food safety [86]. Similarly, [87] proposed multicriteria decision methods and structural equations modeling (SEM), aiming to maximize the total value of sustainable purchase performance and partial least squares SEM (PLS-SEM), which facilitate the development of sustainable SC practices and have an effect in competitive advantage [21]. Some solution methods used " constraints to solve multi-objective models [78], [80] , as well as using Pareto optimality [79], [86], GAMS software [85], [84], hybrid multi-objective approaches [81], and genetic algorithms [83], [77].

Regarding simulation models, [66] evaluate two scenarios where logistic costs, product quality, energy use, and CO2 emissions are compared. [88] also used simulation based on agents, seeking to minimize logistic costs along with the minimization of total costs and total carbon emissions. In system dynamics, [89] simulates Hubbert’s peak, which considers the lifespan of coal deposits and evaluates their long-term sustainability. [90] analyze the robust closed loop SC operations and present relative strategies with robust H1 controlling methods. Through system dynamics, [91] evaluates the selection of sustainable suppliers and aims to ensure that suppliers maintain their status for a long period of time.

[52] simulate and study the use of multimodal transportation on the performance of the food supply logistics of uchuva SCs through the system dynamics approach. They consider transportation costs, total transportation time, food loss due to transportation and inventory, and CO2 emissions caused by mode of transportation. [92] simulate and evaluate sustainability in a closed supply chain, considering customer satisfaction and impact and the green image factor as an environmental factor. [93]use simulation based on GIS (Geographic Information Systems) to evaluate electric demand and supply at the neighborhood level through discrete simulation, seeking to reduce the negative impact on customers satisfaction levels, as well as the way to optimize routes and compare sevarl solutions in terms of truck fleets to reduce CO2 emissions. [94] explore the possibilities of applying the reengineering process available with RFID in closed cycle SCs, and [95], also using discrete simulation, analyze the consequences of risk in terms delay/disturbance using the Monte Carlo Simulation.

Among the environments, we can highlight well-known software such as STELLA [89], VENSIM [92], [91], iThink [52], and ARENA [94]. There are also specialized environments like ALADIN [66] y PROSIM [96].

We found 19 articles about modeling with environmental and economic actors, 9 of which include the three pillars: social, environmental and, economic. However, none of them had a solely socioeconomic or social-environmental focus. [97] did not find either any model that considered only the social environmental aspect; but they found 3 articles that considered the socio-economic aspect. Similarly, [10] found 28 articles with the three pillars, 61 with environmental-economic, 2 with social-economic, and 1 with social-environmental approaches.

Fig 2: Sustainability approaches in modeling according to the reviewed articles

Trends and future investigations

There is a bias in terms of the number of articles dealing exclusively with research on the environmental impact of SCs. Thus, there is a need to evaluate the three sustainability pillars to understand the interrelationship between the social, economic, and environmental dimensions [9]. Moreover, the analysis should be expanded beyond greenhouse gas emissions to encompass lifecycle approaches that include new social measures [81];, [86].

A series of important contributions to the analysis of SC performance in terms of sustainability and the importance of its three pillars in decision-making strategies using quantitative models have been observed [87]. In the same way, the need to carry out theoretical and empirical research about the way forward to fulfill the SCS has been stated [97].

Furthermore, it is important to develop models that consider uncertainty and risk [81], since most models are deterministic, and complexity has not yet been modeled by including environmental and social factors [86]. Also, it is recommended to integrate tactical and strategic decisions into the models [97]. Moreover, it is required to analyze SC design with different structures and configurations to evaluate the pillars of sustainability [75], [97].

Additionally, the potential for collaboration is seen as a competitive advantage [55]. In this sense, there is growing number of research groups investigating the relationships between collaboration in terms of sustainability and company performance based on economic, environmental, and social indicators [55], with quantitative methods being an opportunity for research on the relationship between sustainability and collaboration.

There is increasing interest in emerging economies [1], [98], [47], circular economy [99], [100], along with circular supply chains [32], [11], [101] and the use of 4.0 technologies in this context [102]. Therefore, future research should be oriented towards topics such as designing for circularity, collaboration, and coordination into CSCM (Circular Supply Chain Management), purchasing and CSC, biodegradable containers for CSCM, and circular consumption.

In Fig. 3, there is a synthesis of the findings of the literature review. Firstly, we found, from the sustainability perspective, how the TBL offers an approach from the 3 dimensions or pillars which has been covered in by literature in traditional SCM, GSCM, and SSCM, with external and internal motivators that drive the manufacturing structure and include sustainable objectives. In the same way, these motivators drive the deployment of social and green SC practices, where it is important to highlight collaboration to involve the parties and to have an impact in SC development. In addition, trade-off are found in the decision-making process within the context of SCs and sustainability, an approach that has raised interest among researchers.

Fig 3: Synthesis of results

Conclusions

From the literature review, we can highlight the fact that the concept of sustainability has gained great relevance in all directions, incorporating itself into the supply chain with its three dimensions, which, beyond economic benefits, are oriented toward the importance of SC actors to contribute positively to the environment and society.

There has been a growing interest in SC research during the last 19 years, particularly in 2019, which witnessed a great interest from scholars in Green and Sustainable Supply Chain Management. It should be noted that SSCM is an extension of GSCM [31], and it includes the 3 dimensions of sustainability, which comes from a bigger understanding of social and environmental aspects.

The relevance of GSCM and SSCM is based upon both internal and external supply chain drivers, which are generated due to pressure from stakeholders and motivated from the benefits that could be gained when sustainable requirements are accomplished. Likewise, these motivators drive the deployment of operational practices containing a series of social and environmental factors that influence the performance of SCs. Therefore, it is possible to find different indicators in the literature to measure environmental impact. However, several authors mention the need for improving the quantifying of social impacts.

Additionally, the literature review shows that collaboration within the SC is a primary factor, as it has positive impacts in sustainable objectives, thus contributing to achieve the aforementioned practices mentioned and improving performance. It is worth delving into the current characteristics required by SC actors, defining indicators to monitor compliance with the principles of sustainability, as well as achieving economic, environmental and social development, the latter being the least referenced in SCM.

When it comes to the modeling and simulation of GSC and SSC, we observed that, in the last decade, scholars have increasingly participated in the modeling of environmental and social factors, which are still a challenge in terms of definition and measurement. In the same way, some authors conclude that there is a need to incorporate risk management and uncertainty into the formal modeling of strategic and tactical decisions, as well as implementing mixed models that allow approaching to the current SC issues.

Thereupon, we can observe that quantitative methods and their distinct applications in different industrial areas are a current research topic. Additionally, circular economy recently merged with this field, given its perceived importance as an alternative to transform productive systems with defined principles and strategies with the objective of being environmentally viable, valuing waste, and optimizing the use of raw materials. Moreover, its implementation requires the participation of all the actors in supply chain and beyond, which is something that we have previously learned about the operation of green and sustainable supply chains. Finally, the incorporation of technology and Industry 4.0 into the fields of sustainable supply chains and circular economy brings research opportunities that open up one of the most promising lines of development for the literature and applied work in the coming years.

References

Appendix

A review of SSCM optimization models in the literature

Table I: A review of SSCM optimization models in the extant literature Multi Objective Particle Swarm Optimization (MOPSO), Multi-objective Hybrid Approach, Multiple Criteria Decision Making (MCDM), Adapted multi-objective variable neighborhood search (AMOVNS), Structural equation modeling (SEM)

Second appendix

Selected articles dealing with simulation in GSCM and SSCM studies

Table II: Selected articles dealing with simulation in GSCM and SSCM studies

Licencia

Derechos de autor 2020 Janna Paola Gamboa Bernal, Carlos Eduardo Moreno Mantilla , Javier Arturo Orjuela Castro

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-CompartirIgual 4.0.

A partir de la edición del V23N3 del año 2018 hacia adelante, se cambia la Licencia Creative Commons “Atribución—No Comercial – Sin Obra Derivada” a la siguiente:

Atribución - No Comercial – Compartir igual: esta licencia permite a otros distribuir, remezclar, retocar, y crear a partir de tu obra de modo no comercial, siempre y cuando te den crédito y licencien sus nuevas creaciones bajo las mismas condiciones.

![Methodology for literature reviews by Rincón-Ballesteros [12]](https://revistas.udistrital.edu.co/index.php/reving/article/download/16926/version/12688/17275/105153/0121-750X-inge-25-03-355-gf1.png)

2.jpg)