DOI:

https://doi.org/10.14483/23448393.22204Published:

2025-12-10Issue:

Vol. 30 No. 3 (2025): September-DecemberSection:

Chemical, Food, and Environmental EngineeringModeling a Fixed-Bed System with Coal Volatiles Post-Combustion for Ceramic Kiln Firing

Modelamiento de un sistema de lecho fijo con poscombustión de volátiles del carbón para hornos de cocción de cerámicos

Keywords:

Secondary air, Ceramic firing, Coal combustion, down-draught kiln, Fixed bed grill, Post-combustion (en).Keywords:

aire secundario, cocción de cerámicos, combustión de carbón, hornos colmena, parrilla de lecho fijo, poscombustión (es).Downloads

Abstract (en)

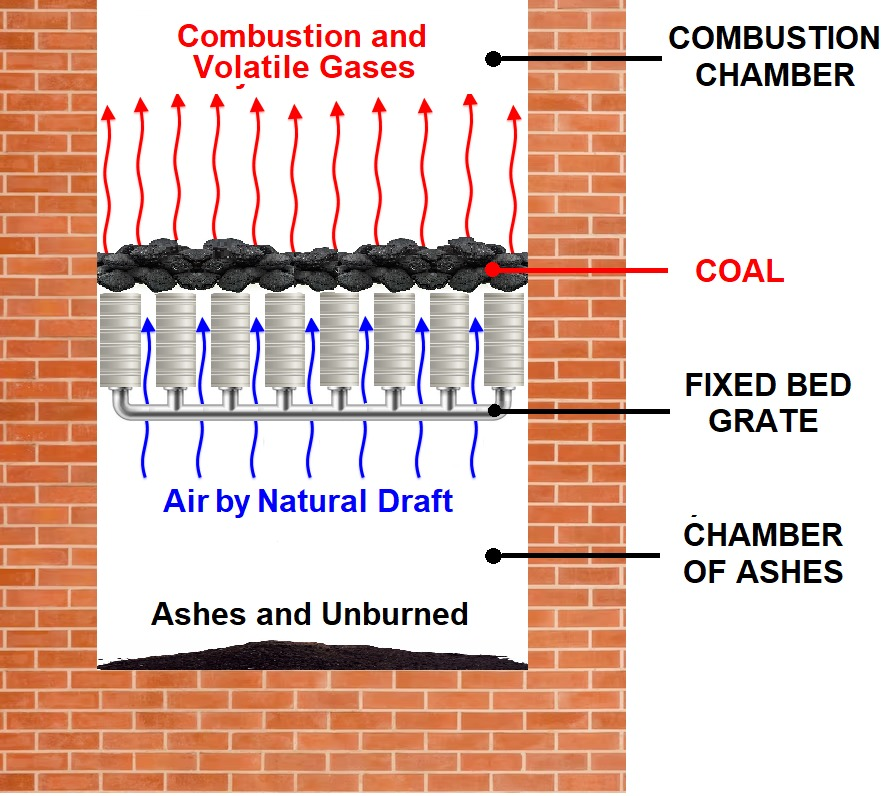

Context: It is estimated that, in Colombia, more than 1300 brick industries consume around 5800 Tcal/year, which are supplied by coal, biomass, wood, and gas combustion. The most commonly used kilns are down-draught, wherein coal combustion is produced on fixed-grate beds, emitting greenhouse gases and other pollutants. As a contribution to solving this problem, this work presents the model of a fixed-bed system with coal volatiles post-combustion.Method: Temperature, time, coal consumption, and combustion products were monitored in a down-draught kiln, in order to determine their mass, energy, and thermal efficiency balances. Coal characterization was performed under ASTM standards, ashes were determined via XRD, XRF, and TGA, and emissions were obtained using a gas analyzer. The thermodynamic model used to design the 3D reactor was based on coal-burning analysis.

Results: The process lasted 3166 min, consuming 2150 kg of coal. The combustion gases exhibited a varying composition of CO2, CO, O2, and hydrocarbons. The temperature on the grate reached 900 °C, and we recorded 1000 °C in the dome and 600 °C at the chimney base. The temperature difference between the dome and the chimney base explains the heat transferred for ceramic baking. The calorific value of the char was 19.52% higher than that of the coal used. The composition of the ash showed silicon oxide, mullite, and goethite. The 3D model consists of a grate with preheater ducts for the secondary air post-combustion of the volatiles.

Conclusions: The outcome of this research was the 3D model of a fixed-bed grate for coal combustion and volatiles post-combustion. With its implementation, we expect to improve air quality and reduce the effects of the process on human health, as well as its operating costs.

Abstract (es)

Contexto: Se estima que, en Colombia, más de 1300 industrias ladrilleras consumen alrededor de 5800 Tcal/año, provenientes de la combustión de carbón, biomasa, leña y gas. Los hornos más comunes son los de tiro descendente, en los cuales la combustión del carbón se realiza sobre parrillas fijas, emitiendo gases de efecto invernadero y otros contaminantes. Como contribución a la solución de este problema, este trabajo presenta el modelo de un sistema de lecho fijo con poscombustión de volátiles del carbón.

Método: Se monitorearon la temperatura, el tiempo, el consumo de carbón y los productos de combustión en un horno de tiro descendente, a fin de determinar los balances de masa, energía y eficiencia térmica. La caracterización del carbón se realizó bajo las normas ASTM, las cenizas se analizaron mediante XRD, XRF y TGA, y las emisiones se determinaron utilizando un analizador de gases. El modelo termodinámico empleado para el diseño del reactor 3D se basó en el análisis de la combustión del carbón.

Resultados: El proceso tuvo una duración de 3166 minutos, con un consumo de 2150 kg de carbón. Los gases de combustión presentaron una composición variable de CO₂, CO, O₂ e hidrocarburos. La temperatura en la parrilla alcanzó los 900 °C, y se registraron 1000 °C en la cúpula y 600 °C en la base de la chimenea. La diferencia de temperatura entre la cúpula y la base de la chimenea explica el calor transferido para la cocción de la cerámica. El poder calorífico del char fue 19.52 % superior al del carbón utilizado. La composición de las cenizas mostró la presencia de óxido de silicio, mullita y goethita. El modelo 3D consiste en una parrilla con conductos precalentadores para el aire secundario destinado a la poscombustión de los volátiles.

Conclusiones: El resultado de esta investigación fue el modelo 3D de una parrilla de lecho fijo para la combustión de carbón y la poscombustión de volátiles. Con su implementación, se espera mejorar la calidad del aire y reducir los efectos del proceso sobre la salud humana, así como sus costos operativos.

References

1] S. Jain, “Development of UNfiRED BRICKS USING INDUSTRIAL WASTE,” 2016. [Online]. Available: https://doi.org/10.13140/RG.2.2.23905.51047

[2] A. Eser, “Essential brick industry statistics in 2023,” ZipDo, 2023. [Online]. Available: https://zipdo.co/statistics/brick-industry/

[3] Dirección de Asuntos Ambientales Sectorial y Urbana., L. F. González Herrera, J. I. Pedraza Vega, M. Gaitán Varón, and Corporación Ambiental Empresarial (CAEM), Portafolio de mejores técnicas disponibles y mejores prácticas ambientales para el sector alfarero y de producción de ladrillo en Colombia. Bogotá DC, Colombia: Ministerio de Ambiente y Desarrollo Sostenible, 2021.

[4] C. David and M. Cabeza, “Panorama sobre modelado de eficiencia energética en hornos ladrilleros colombianos”, 2023. [Online]. Available: https://www.cdtdegas.com/images/Descargas/Nuestra_revista/MetFlu16/1_Modelado_eficiencia_hornos.pdf

[5] I. M. Guerrero, E. A. Goldstein, J. H. Stein, H. Acquay, and M. Sarraf, “Introducing energy-efficient clean technologies in the brick sector of Bangladesh,” World Bank, 2011. [Online]. Available: https://documents.worldbank.org/en/publication/documents-reports/documentdetail/770271468212375012

[6] C. W. Schmidt, “Modernizing artisanal brick kilns: A global need,” Environ. Health Perspect., vol. 121, no. 8, pp. A244–A 246, Aug. 2013, https://doi.org/10.1289/ehp.121-A242

[7] M. Zavala et al., “Black carbon, organic carbon, and co-pollutant emissions and energy efficiency from artisanal brick production in Mexico,” Atmos. Chem. Phys., vol. 18, no. 8, pp. 6023–6037, Apr. 2018. https://doi.org/10.5194/acp-18-6023-2018

[8] K. M. ud Darain et al., “Energy efficient brick kilns for sustainable environment,” Desalin. Water Treat., vol. 57, no. 1, pp. 105–114, Jan. 2016. https://doi.org/10.1080/19443994.2015.1012335

[9] M. R. Riazi and R. Gupta, Coal Production and Processing Technology. Boca Ratón, Florida, USA: CRC Press, 2016.

[10] C. Weyant et al., “Brick kiln measurement guidelines: Emissions and energy performance,” Aug. 2016. [Online]. Available: https://www.ccacoalition.org/sites/default/files/resources/BC_BrickKilns_GuidanceDocument_Final.pdf

[11] I. Blasco, J. Ferrero, C. García, and R. González, “Análisis y descripción gráfica del funcionamiento de los hornos cerámicos,” 2015. [Online]. Available: https://ceramica.name/img/descargas/Hornos%20ceramicos.pdf

[12] A. W. Date, Analytic combustion: With thermodynamics, chemical kinetics, and mass transfer. Bombay, India: Cambridge University Press, 2011.

[13] J. M. Samet, “Introduction,” in Air pollution and cancer, K. Straif, A. Cohen, and J. Samet, Eds. Lyon, France: International Agency for Research on Cancer (IARC), World Health Organization, 2013.

[14] N. Cross, Métodos de diseño: estrategias para el diseño de productos, F. R. Pérez Vázquez, Trad. México DF, Mexico: Limusa Wiley, Grupo Noriega Editores, 2002.

[15] K.-C. Xie, Structure and reactivity of coal. A survey of selected Chinese coals, Beijing, China: SpringerLink, 2015. https://doi.org/10.1007-978-3-662-47337-5

[16] V. Raghavan, Combustion technology: Essentials of flames and burners. London, UK: John Wiley & Sons Ltd, 2016.

[17] D. A. Bell, B. F. Towler, and M. Fan, Coal gasification and its applications. Oxford, UK: Elsevier, 2011. https://doi.org/10.1016/b978-0-8155-2049-8.10015-4

[18] Y. Cengel, Transferencia de calor y masa: un enfoque práctico, 3rd ed. México DF, Mexico: McGraw-Hill Interamericana, 2007.

[19] Servicio Geológico Colombiano, El carbón colombiano. Recursos, reservas y calidad, 2nd ed., vol. 32. Bogotá DC, Colombia: Libros del Servicio Geológico Colombiano, 2012.

[20] Y. Han et al., “Different formation mechanisms of PAH during wood and coal combustion under different temperatures,” Atmos. Environ., vol. 222, art. 117084, 2020. https://doi.org/10.1016/j.atmosenv.2019.117084

[21] T. G. Bridgeman, J. M. Jones, and A. Williams, “Overview of solid fuels, characteristics and origin,” in Handbook of Combustion, Vol. 4: Solid Fuels, M. Lackner, F. Winter, and A. K. Agarwal, Eds. Weinheim, Germany: Wiley-VCH, 2010, ch. 1, pp. 1-30. https://doi.org/10.1002/9783527628148.hoc055

[22] L. F. Velásquez Vallejo, J. F. D. L. C. Morales, J. F. Sánchez Morales, and M. A. Marín Laverde, “Remoción de carbón inquemado de las cenizas volantes producidas en el proceso de combustión de carbón,” Rev. Energ., vol. 38, pp. 107–112, Dec. 2007.

[23] J.-J. Weng, Z.-Y. Tian, Y.-X. Liu, Y. Pan, and Y.-N. Zhu, “Investigation on the co-combustion mechanism of coal and biomass on a fixed-bed reactor with advanced mass spectrometry,” Renew. Energy, vol. 149, pp. 1068–1076, 2020. https://doi.org/10.1016/j.renene.2019.10.110

[24] C. Chen, Q. Yang, R. Zhang, and D. Liu, “Assessment on combustion chemistry of coal volatiles for various pyrolysis temperatures,” J. Energy Inst., vol. 104, pp. 22–34, Oct. 2022. https://doi.org/10.1016/j.joei.2022.07.001

[25] A. Abbas et al., “Assessment of long-term energy and environmental impacts of the cleaner technologies for brick production,” Energy Rep., vol. 7, pp. 7157–7169, Nov. 2021. https://doi.org/10.1016/j.egyr.2021.10.072

[26] J. G. Speight, The chemistry and technology of coal, 3rd ed. Abingdon, Oxfordshire, UK: Taylor & Francis Group, 2013.

[26] L. Bartoňová, “Unburned carbon from coal combustion ash: An overview,” Fuel Proc. Tech., vol. 134, pp. 136–158, Feb. 2015. https://doi.org/10.1016/J.FUPROC.2015.01.028

[27] S. V. Vassilev, C. G. Vassileva, and N. L. Petrova, “Thermal behaviour of biomass ashes in air and inert atmosphere with respect to their decarbonation,” Fuel, vol. 314, art. 122766, Apr. 2022. https://doi.org/10.1016/J.FUEL.2021.122766

[28] P. Kumar and B. K. Nandi, “Assessment of combustion characteristics of high ash Indian coal, petroleum coke and their blends for cement industry using TGA,” Cleaner Chem. Eng., vol. 5, art. 100091, 2023. https:/doi.org/10.1016/j.clce.2022.100091

[29] H. Valdes, J. Vilches, G. Felmer, M. Hurtado, and J. Figueroa, “Artisan brick kilns: State-of-the-art and future trends,” Sustainabilty, vol. 12, no. 18, art. 7724, 2020. https://doi.org/10.3390/su12187724

[30] S. M. K. S. Rahman, “Assessment of brick kiln technologies of Bangladesh,” MS thesis, Inst. Approp. Tech. (IAT), Bangladesh Univ. Eng. Tech. (BUET), Dhaka, Bangladesh, 2019.

[31] K. W. Ragland and K. M. Bryden, Combustion engineering, 2nd ed. Boca Raton, FL, USA: CRC Press, 2010.

How to Cite

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Download Citation

License

Copyright (c) 2025 Marco Antonio Ardila Barragán , Maria del Pilar Triviño Restrepo, Luis Fernando Lozano Gómez, Naren Natalia Ardila Otálora, Brigith Daniela Cruz Molina, Fabián Rolando Jiménez López, Alfonso López-Díaz, Jaime Alberto Riaño Villamizar

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

From the edition of the V23N3 of year 2018 forward, the Creative Commons License "Attribution-Non-Commercial - No Derivative Works " is changed to the following:

Attribution - Non-Commercial - Share the same: this license allows others to distribute, remix, retouch, and create from your work in a non-commercial way, as long as they give you credit and license their new creations under the same conditions.

2.jpg)