DOI:

https://doi.org/10.14483/23448393.18228Published:

2022-11-20Issue:

Vol. 28 No. 1 (2023): January-AprilSection:

Industrial EngineeringCosts of Timber Houses in Different Standards and Productions in Brazil

Costos de casas en madera en diferentes estándares y producciones de Brasil

Keywords:

construcción, habitación, industria de la madera, estándar de construcción, costo, entrevista (es).Keywords:

construction, building standard, cost, interview, timber industry, housing (en).Downloads

References

V. A. De Araujo et al., “Wooden residential buildings – A sustainable approach,” Bull. Transilv. Univ. Bras. II: For. Wood Ind. Agric. Food Eng., vol. 9, no. 58, pp. 53-62, 2016.

A. Sujová, P. Hlaváčková, and K. Marcineková, “The trade competitiveness of furniture products,” Drewno, vol. 58, pp. 101-115, 2015. https://doi.org/10.12841/wood.1644-3985.104.09

American Institute of Timber Construction, Timber Construction Manual, 6th ed., Hoboken, NJ, USA: Wiley, 2012. DOI: https://doi.org/10.1002/9781118279687

L. V. Buonfiglio, “Housing of social interest,” Mercator, vol. 17, p. 1-16, 2018. https://doi.org/10.4215/rm2018.e17004 DOI: https://doi.org/10.4215/rm2018.e17004

IBGE, Atlas do censo demográfico 2010, Rio de Janeiro, Brazil: IBGE, 2013.

J. Piqué Del Pozo, Manual de diseño para maderas del grupo Andino, 1st ed., Lima, Peru: PADT/REFORT, 1984.

J. Natterer, J. L. Sandoz, and M. Rey, Construction en bois: matériau, technologie et dimensionnement, 1st ed., Lausanne, Switzerland: PPUR, 2004.

R. L. Mello, “Projetar em madeira: uma nova abordagem,” Master’s thesis, Univ. Brasilia, Brazil, 2007. [Online]. Available: https://repositorio.unb.br/handle/10482/3133

Y. Benoit and T. Paradis, Construction de maisons à ossature bois, 4th ed., Saint-Germain, France: Eyrolles, 2008.

F. Ching, Técnicas de construção ilustradas, 4th ed., Porto Alegre, Brazil: Brookman, 2010.

T. Herzog, J. Natterer, R. Schweitzer, M. Volz, and W. Winter, Timber construction manual, 1st ed., Basel, Switzerland: Birkhäuser, 2012.

L. Morgado, M. C. Guedes, J. G. Ferreira, and H. Cruz, “Classificação de sistemas de construção em madeira para habitação,” in IV Cong. Nac. Const., Coimbra, Portugal, 2012, pp. 1-12.

P. Neufert, and L. Neff, Casa • apartamento • jardim: projetar com conhecimento • construir corretamente. 2nd ed., Barcelona, Spain: Gustavo Gili, 2012.

M. Fuchs and J. Mussier, Construire avec le bois, 1st ed., Paris, France: Le Moniteur, 2019.

V. A. De Araujo et al., “Classification of wooden housing building systems,” BioResources, vol. 11, pp. 7889-7901, 2016. https://doi.org/10.15376/biores.11.3.DeAraujo DOI: https://doi.org/10.15376/biores.11.3.DeAraujo

V. A. De Araujo, C. M. Gutiérrez-Aguilar, J. Cortez-Barbosa, M. Gava, and J. N. Garcia, “Disponibilidad de las técnicas constructivas de habitación en madera, en Brasil,” Rev. Arq., vol. 21, pp. 68-75, 2019. https://doi.org/10.14718/RevArq.2019.21.1.2014 DOI: https://doi.org/10.14718/RevArq.2019.21.1.2014

E. A. Kuhn and P. F. Nerbas, “CUB e projetos-padrão pela NBR 12721,” in Avaliação de imóveis e perícias, E. A. Kuhn, L. P. Pereira, and P. F. Nerbas, eds., Curitiba, Brazil: IESDE, 2009, pp. 39-46.

Presidência da República, Decreto lei n. 4591, 1964. [Online]. Available: http://www.planalto.gov.br/ccivil_03/leis/l4591.htm

ABNT NRT, Avaliação de custos unitários de construção para incorporação imobiliária e outras disposições para condomínios edilícios – procedimento, Rio de Janeiro, Brazil: ABNT, 2006.

S. Sakuragawa, “Change in the impression of rooms with interior wood finishes arranged differently: questionnaire survey with the use of photographs for the analysis of impressions of rooms concerning living activities,” J. Wood Sci., vol. 52, pp. 290-294, 2006. https://doi.org/10.1007/s10086-005-0764-1 DOI: https://doi.org/10.1007/s10086-005-0764-1

W. Fujisaki, M. Tokita, and K. Kariya, “Perception of the material properties of wood based on vision, audition and touch,” Vision Res., vol. 109, pp. 185-200, 2015. https://doi.org/10.1016/j.visres.2014.11.020 DOI: https://doi.org/10.1016/j.visres.2014.11.020

G. Janin, J. Goncalez, R. Ananías, B. Charrier, G. F. Silva, and A. Dilem, A. “Aesthetics appreciation of wood colour and patterns by col-orymetry. Part 1. Colorimetry theory for the Cielab system,” Maderas-Cienc. Tecnol., vol. 3, pp. 3-13, 2001. https://doi.org/10.4067/S0718-221X2001000100001 DOI: https://doi.org/10.4067/S0718-221X2001000100001

J. Rice, R. A. Kozak, M. J. Meitner, and D. H. Cohen, “Appearance wood products and psychological well-being,” Wood Fiber Sci., vol. 38, pp. 644-659, 2006.

A. Manuel, R. Leonhart, O. Broman, and G. Becker, “Consumers’ perceptions and preference profiles for wood surfaces tested with pairwise comparison in Germany,” Ann. For. Sci., vol. 72, pp. 741-751, 2015. https://doi.org/10.1007/s13595-014-0452-7 DOI: https://doi.org/10.1007/s13595-014-0452-7

C. P. Szücs, “Sistema Stella-UFSC: avaliação e desenvolvimento de sistema construtivo em madeira de reflorestamento voltado para programas de habitação social,” in Coletânea Habitare, 1st ed, L. C. Bonin and S. R. Amorim, eds., 1st ed., Porto Alegre, Brazil: Antac, 2006, pp. 66-115.

L. Lung and M. Shaurette, “Working collaboratively in design and construction to encourage green building construction for Peru,” Rev. Ing. Const., vol. 33, pp. 183-192, 2018. https://doi.org/10.4067/S0718-50732018000200183 DOI: https://doi.org/10.4067/S0718-50732018000200183

A. Friedman, “Prefabrication versus conventional construction in single‐family wood‐frame housing,” Build. Res. Inf., vol. 20, pp. 226-228, 1992. https://doi.org/10.1080/09613219208727210 DOI: https://doi.org/10.1080/09613219208727210

A. M. Hualpa and C. A. López, “Algoritmo de dimensionamiento de almacenes para empresas de edificación en el sector de la construc-ción,” Ing., vol. 20, pp. 189-208, 2015. https://doi.org/10.14483/udistrital.jour.reving.2015.2.a02 DOI: https://doi.org/10.14483/23448393.8381

J. P. Frigo and D. S. Silveira, “Educação ambiental e construção civil: práticas de gestão de resíduos em Foz do Iguaçu-PR,” REMOA, vol. 9, pp. 1938-1952, 2012. https://doi.org/10.5902/223613085678 DOI: https://doi.org/10.5902/223613085678

F. H. Sabbatini, Alvenaria estrutural: materiais, execução da estrutura e controle tecnológico, Brasília, Brazil: Caixa Econômica Federal, 2003.

V. A. De Araujo, J. C. Biazzon, J. Cortez-Barbosa, E. A. M. Morales, M. Gava, and J. N. Garcia, “Timber housing production systems in Brazil,” Bull. Transilv. Univ. Bras. II: For. Wood Ind. Agric. Food Eng., vol. 13, no. 62, pp. 69-80, 2020. https://doi.org/10.31926/but.fwiafe.2020.13.62.1.6 DOI: https://doi.org/10.31926/but.fwiafe.2020.13.62.1.6

G. Pardalis, K. Mahapatra, and B. Mainali, “Swedish construction MSEs: simply renovators or renovation service innovators?,” Build. Res. Inf., vol. 48, pp. 67-83, 2020. https://doi.org/10.1080/09613218.2019.1662713 DOI: https://doi.org/10.1080/09613218.2019.1662713

Sinduscon-MG, Saiba mais: custo unitário básico (CUB/m2), 1st ed., Belo Horizonte, Brazil: Sinduscon-MG, 2013.

A. Fadul, PIB do setor de construção civil caiu 2,7% no 1º trimestre do ano, mostra estudo da FIESP, São Paulo: FIESP, 2015. [Online]. Available: http://www.fiesp.com.br/noticias/pib-do-setor-de-construcao-civil-caiu-27-no-1o-trimestre-do-ano-mostra-estudo-da-fiesp/

D. Forrest, “An analysis of house price differentials between English regions,” Reg. Stud., vol. 25, pp. 231-238, 1991. https://doi.org/10.1080/00343409112331346447 DOI: https://doi.org/10.1080/00343409112331346447

B. Reilly and R. Witt, “Regional house prices and possessions in England and Wales: An empirical analysis,” Reg. Stud., vol. 28, pp. 475-482, 1994. https://doi.org/10.1080/00343409412331348406 DOI: https://doi.org/10.1080/00343409412331348406

R. K. Bissoondeeal, “The links between regional house prices and share prices in the UK,” Reg. Stud., vol. 55, pp. 256-268, 2020. https://doi.org/10.1080/00343404.2020.1795108 DOI: https://doi.org/10.1080/00343404.2020.1795108

IBGE, Sistema nacional de pesquisa de custos e índices da construção civil – SINAPI, Rio de Janeiro, Brazil: IBGE, 2017. [Online]. Availa-ble: https://sidra.ibge.gov.br/pesquisa/sinapi/tabelas

V. A. De Araujo et al., “Difficulties of wooden housing production sector in Brazil,” Wood Mater. Sci. Eng., vol. 15, pp. 87-96, 2018. https://doi.org/10.1080/17480272.2018.1484513 DOI: https://doi.org/10.1080/17480272.2018.1484513

Raosoft, “Raosoft Sample Size Calculator,” 2004. [Online]. Available: http://www.raosoft.com/samplesize.html

R. M. Pinheiro, G. C. Castro, H. H. Silva, and J. M. G. Nunes, Pesquisa de mercado, 1st ed., Rio de Janeiro, Brazil: FGV, 2011.

J. D. Wagner, Ultimate guide to house framing: Plan, design, build, 3rd ed., Upper Saddle River, NJ, USA: Creative Homeowner, 2009.

V. A. De Araujo, J. Cortez-Barbosa, J. N. Garcia, M. Gava, C. Laroca, and S. F. César, “Woodframe: Light framing houses for developing countries,” Rev. Const., vol. 15, pp. 78-87, 2016. https://doi.org/10.4067/S0718-915X2016000200008 DOI: https://doi.org/10.4067/S0718-915X2016000200008

G.J. Zenid, Madeira: uso sustentável na construção civil, 2nd. ed., São Paulo, Brazil: IPT, 2009.

S. C. Bauch, G. S. Amacher, and F. D. Merry, “Costs of harvesting, transportation and milling in the Brazilian Amazon: Estimation and policy implications,” Forest Policy Econ., vol. 9, p. 903-915, 2007. https://doi.org/10.1016/j.forpol.2006.07.004 DOI: https://doi.org/10.1016/j.forpol.2006.07.004

S. F. César, “Chapas de madeira para vedação vertical de edificações produzidas industrialmente: projeto conceitual,” Doctoral disserta-tion, Fed. Univ. Santa Catarina, Brazil, 2002. [Online]. Available: https://repositorio.ufsc.br/handle/123456789/83182

K. Imaguire Junior, and M. R. G. Imaguire, A casa de araucária, Volume 1, 1st ed., Curitiba, Brazil: Arquibrasil, 2011.

C. A. Szücs, and F. D. Batista, “A arquitetura de madeira na região de Curitiba: estudo comparativo entre a casa tradicional e contempo-rânea,” in II Enc. Lat.-Amer. Edif. Comun. Sust., Campo Grande, Brazil, 1997, pp. 798-807.

A. C. Hoffmann, and S. C. A. Pelegrini, “A técnica de se construir em madeira: um legado do patrimônio cultural para a cidade de Marin-gá,” in IV Cong. Int. Hist., Maringá, Brazil, 2009, pp. 1-9. DOI: https://doi.org/10.4025/4cih.pphuem.732

J. E. P. Sánchez, F. A. Martitegui, C. A. Martitegui, M. A. G. Álvarez, F. P. Sánchez, and M. A. R. Nevado, Casas de madera, Madrid, Spain: AITIM, 1995.

M. Sacco and G. C. Stamato, “Light wood frame – construções com estrutura leve de madeira,” Téchne, no. 140, pp. 1-9, 2008.

J. C. Molina and C. Calil Junior, “Sistema construtivo em wood frame para casas de madeira,” Semin., Ciênc. Exatas Tecnol., vol. 31, pp. 143-156, 2010. https://doi.org/10.5433/1679-0375.2010v31n2p143 DOI: https://doi.org/10.5433/1679-0375.2010v31n2p143

Tecverde, Como projetar em wood frame: principais características do sistema construtivo wood frame e diretrizes para desenvolvimen-to de projetos arquitetônicos, 1st ed., Curitiba, Brazil: Tecverde, 2011.

C. L. Eisfeld and R. Berger, “Análise das estruturas de mercado das indústrias de painéis de madeira (compensado, MDF e OSB) no Estado do Paraná,” Floresta, vol. 42, pp. 21-34, 2012. https://doi.org/10.5380/rf.v42i1.26289 DOI: https://doi.org/10.5380/rf.v42i1.26289

D. López and T. M. Froese, “Analysis of costs and benefits of panelized and modular prefabricated homes,” Procedia Eng., vol. 145, pp. 1291-1297, 2016. https://doi.org/10.1016/j.proeng.2016.04.166 DOI: https://doi.org/10.1016/j.proeng.2016.04.166

K. Orlowski, “Assessment of manufacturing processes for automated timber-based panelised prefabrication,” Buildings, vol. 9, art. 125, 2019. https://doi.org/10.3390/buildings9050125 DOI: https://doi.org/10.3390/buildings9050125

C. D. Loss, A. P. Gomes, A. G. Goldoni, L. D. Tagliari, and L. S. Maculan, “Valor imobiliário de habitações populares de acordo com pa-drões de acabamento”, in XVI Enc. Nac. Tecnol. Amb. Const., São Paulo, 2016, pp. 5557-5571.

Y. Wang, X. Xue, T. Yu, and Y. Wang, “Mapping the dynamics of China’s prefabricated building policies from 1956 to 2019: A bibliometric analysis,” Build. Res. Inf., vol. 49, pp. 216-233, 2021. https://doi.org/10.1080/09613218.2020.1789444 DOI: https://doi.org/10.1080/09613218.2020.1789444

E. Wiegand, and M. Ramage, “The impact of policy instruments on the first generation of tall wood buildings,” Build. Res. Inf., vol. 50, no. 3, pp. 255-275, 2021. https://doi.org/10.1080/09613218.2021.1905501 DOI: https://doi.org/10.1080/09613218.2021.1905501

J. Carro, F. Flores, I. Flores, and R. Hernández. “Industria 4.0 y manufactura digital: un método de diseño aplicando ingeniería inversa,” Ing., vol. 24, no. 1, pp. 6-28, 2019. https://doi.org/10.14483/23448393.13821 DOI: https://doi.org/10.14483/23448393.13821

P. Miraj, M. A. Berawi, and S. R. Utami, “Economic feasibility of green office building: Combining life cycle cost analysis and cost-benefit evaluation,” Build. Res. Inf., vol. 49, no. 6, pp. 624-638, 2021. https://doi.org/10.1080/09613218.2021.1896354 DOI: https://doi.org/10.1080/09613218.2021.1896354

FIESP, “Levantamento inédito mostra déficit de 6,2 milhões de moradias no Brasil,” 2016. [Online]. Available: http://www.fiesp.com.br/noticias/levantamento-inedito-mostra-deficit-de-62-milhoes-de-moradias-no-brasil/

How to Cite

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Download Citation

Recibido: 2 de julio de 2021; Revisión recibida: 2 de mayo de 2022; Aceptado: 22 de junio de 2022

Abstract

Context:

Timber construction is not among the most popular options due to cultural issues in Brazil. Timber housing standards and costs remain uncertain subjects, and this study seeks to investigate these secular gaps.

Method:

Basic unitary costs for different finishing standards and production types were measured through face-to-face interviews led by a semi-structured questionnaire. A margin of error was used to validate all results. Entrepreneurs from six Brazilian states were randomly interviewed to obtain a representative sample.

Results:

The sampling exceeded 50% of the sector population and provided significant outcomes. More than 40% of timber housing techniques showed competitive costs in comparison with masonry. There are feasible alternatives of timber housing for the different scenarios analyzed.

Conclusions:

Timber houses are economically viable in Brazil, even compared to traditional examples built via masonry. Attractive costs for all social classes symbolize a strong factor in conquering housing markets.

Keywords:

construction, housing, timber industry, building standard, cost, interview..Resumen

Contexto:

La construcción en madera no está entre las opciones más populares debido a problemas culturales en Brasil. Los estándares y costos de la habitación en madera siguen siendo temas inciertos, y este estudio busca investigar estas brechas seculares.

Método:

Los costos unitarios básicos para diferentes estándares de acabado y tipos de producción se midieron a través de entrevistas cara a cara dirigidas por un cuestionario semiestructurado. Se utilizó un margen de error para validar todos los resultados. Se entrevistó aleatoriamente a empresarios de seis estados brasileños para obtener una muestra representativa.

Resultados:

El muestreo superó el 50% de la población del sector y proporcionó resultados significativos. Más del 40% de las técnicas de construcción en madera mostraron costos competitivos en comparación con la albañilería. Existen alternativas viables de vivienda en madera en los diferentes escenarios analizados.

Conclusiones:

Las casas de madera son económicamente viables en Brasil, incluso en comparación con los ejemplos tradicionales construidos en albañilería. Los costos atractivos para todas las clases sociales simbolizan un factor fuerte en la conquista de los mercados inmobiliarios.

Palabras clave:

construcción, habitación, industria de la madera, estándar de construcción, costo, entrevista..Introduction

Timber houses are mainly durable goods, as construction and furniture have value-added production in the wood industry chain 1), (2. Timber framing construction can be custom-fabricated to provide an infinite variety of unique but cost-effective architectural forms and arrangements 3.

In Brazil, timber housing remains an unknown topic, especially for academics focused on distant fields of forestry and wood science and technology. For example, in a relevant and recent social housing study of the Brazilian context, 4 does not clearly define and exemplify timber housing techniques with a possible distinction between permanent wood-based houses and provisional households, which leads her readers to misunderstand such relevant sound and robust applications.

This misconception is due to a misinformation of local people and a lack of consideration and standardization of each existing timber housing technique by the Brazilian Institute of Geography and Statistics (IBGE) in its current local demographic census, which is described by 5. Fortunately, the right designation about the available timber construction and its characteristics has already been minutely approached around the world, chronologically, by 1), (3), (6)-(13 and 14, and its identification was richly specified according to construction technique for housing by 15 and 16.

Ignorance about timber houses still prevails worldwide, especially regarding their features by construction technique. This deficiency justifies the development of more timber housing approaches.

For example, the construction industry has only prioritized masonry- and steel-based techniques in the national market tables about sale costs of buildings. In Brazil, timber houses have been manufactured to supply national and international markets 1, 15. However, the lack of sale costs per technique has contributed to the low popularity and complete ignorance regarding timber housing construction.

Despite the perceptible presence of this sector, Brazil does not have market data on the sale costs of available timber-based buildings. It is likely that the existence of multiple timber housing techniques and production systems can be a limiting factor in obtaining a national sale costs tables. Economic data are a central issue for the construction sector and its customers. Thereupon, this study aims to evaluate the basic unitary costs of timber housing techniques in Brazil through economic specifications by different building production methods and finishing standards. This initiative will solve this sectoral demand and allow comparing the available techniques in economic terms.

Workmanship standards for construction

The identification of differences among workmanship standards is a crucial topic in construction, given that the Brazilian real estate market was looked upon with suspicion until the 1960s. This, due to the absence of numerical standards regarding cost composition 17. According to Decree 4591 of December 1964 18, the standard of a construction is defined as “low, average or high, taking into account the following applied aspects: finishing condition, raw material quality, comfort innovation, equipment, and number of lifts”. In short, a construction standard involves the average evaluation of a complete residence, according to its general particularities, which include its finishing and built spaces.

The Brazilian standard document titled NBR 12721 19 prescribes three examples of standards for a single-family residence, which are identified according to its area and basic features (Table I).

Source: adapted from ABNT NBR 12721 (19).

Table I: Housing standards and characteristics according to size and layout

Residence standard

Equivalent area (m2)

Real area (m2)

Composition

Low

51,94

58,64

Two bedrooms, living room, bathroom, kitchen, and area for washing tank

Average

99,47

106,44

Three bedrooms (a suite with bathroom), lavatory, living room, circulation, kitchen, service room with bathroom, and porch (car open space)

High

210,44

224,82

Four bedrooms (a suite with bathroom and closet and a suite with bathroom), lavatory, three rooms (living, dinner and extra room), complete service area, kitchen, and porch (car open space)

As for the finishing of single-family housing, 19 regulates basic specifications in order to delimit budget estimation. The popular standard is usually classified into the lower level because of the large production of compact single-story houses without any relevant aesthetic and technological demand, although two-bedroom buildings can be produced in this category.

Table II outlines some specifications and examples of raw materials according to the expected workmanship standards for residences.

Source: adapted from ABNT NBR 12721 (19).

Table II: Housing standards and characteristics according finishing and material

Residence standard

Specification type

Example of construction material

Low

Flooring (room, bedroom, etc.) Internal/external doors Hydraulic parts

Enamelled ceramics (20 x 20 cm) Waxed solid timber Simple metal for cold water

Average

Flooring (room, bedroom, etc.) Internal/external doors Hydraulic parts

Enamelled ceramics (40 x 40 cm) Satin enamel plywood Simple metal for cold and hot water

High

Flooring (room, bedroom, etc.) Internal/external doors Hydraulic parts

Scraped and resin-coated board (lumber) Semi-hollow wood without painting Luxury metal for cold water

From a structural perspective, any masonry building following the simple and popular standard and placed in a low-income community and/or region requires and uses the same inputs (bricks, cement, sand, etc.) as a high standard edification in a high-income zone or gated community.

Regardless of the construction standard (i.e., from popular to high), all masonry houses are conceptually based on the same low-technology construction practices. Only in specific options, due to factors related to greater thermal and/or acoustic insulation, a greater robustness of the walls of these houses results in greater wall thickness and represents a differential possibility. However, this strategy is based on the same technology as conventional masonry building. In short, double wall layers or larger bricks can solve this demand. Therefore, only three basic factors are more perceptible in the differentiation of masonry housing examples: volumetry, size, and finishing standard. These attributes accentuate a greater visual and economic distinction, which makes them differ- ential aspects in identifying houses with different standards.

In contrast, a timber housing example may be structurally identified in at least 15 distinct construction techniques with singular features and many particularities, as defined by 15), (16. For example, timber-based construction techniques such as half-timbered frame, post-and-beam, and stick houses have robust framing made of lumber (hand-hewn or sawn wood), which is exposed and freestanding, as well as sealed with non-essential structural materials. Meanwhile, log-homes and horizontal clapboards between studs have solid walls based on wooden logs with a double function: freestanding and sealing roles. Similarly, a modular construction with crosslaminated timber (CLT) is produced with three dimensional rigid panels, therefore classified as engineered wood products, whose walls serve for both sealing and structural support.

In contrast, different woodframe variations are known by lightweight compact framing, with varied prefabricated features, whose wall structure is formed by lumber studs and covered by structural panels applied in order to brace and seal the whole set, forming a ‘sandwiched’ wall. Another type is formed by two construction techniques based on industrialized lumber. Clapboard-and-wainscot and nailed clapboard (vertically and horizontally oriented) houses are prefabricated solutions formed by compact framing sealed by lumber from native or planted forests. In both examples, walls are integrally made from industrialized lumber of the same or multiple wood species, sizes and geometries. Lumber clapboards, wainscots (to seal wall spaces), and thin studs are used to form the structure and seal it. These elements are fixed by metallic nails. Wall constitution and finishing are two attributes that distinguish each example, since nailed clapboard houses are focused on noble markets and clapboard and wainscot buildings are oriented towards popular and rural demands. Thus, the structural concept of different timber buildings represents the main typical feature that contrasts each construction technique.

Unlike masonry houses, wood acts as a structural and sealing element 15), and it is a suitable material for the composition of living spaces 20. In addition, 21 stated that wood has elements of robustness, pleasure, singularity, rarity, and sophistication. Furthermore, wood surfaces are aesthetically pleasing 22)-(24, which are associated with sustainable architectural materials 25. Also, lower lifecycle costs compensate the higher costs of green buildings 26. In fact, building costs should be considered as an important factor in timber construction, even though there are multiple alternatives to supply different markets. However, few studies have estimated the costs of different timber techniques as the comparison of prefabrication and conventional systems led by 27.

Construction cost and its perspective in Brazil

Informality has been a sectoral problem that interferes with different stages of construction, such as provision and storage, delivery times, and costs 28.

In Brazil, the construction sector concentrates a disqualified technical workforce, since it is focused on artisanal production of many construction techniques 29. After years of adaptation and development in the Brazilian territory, structural masonry was widely consolidated in the 1980s, becoming the most traditional method 30.

Timber houses are produced both in more rudimentary artisanal styles and modern modalities stemming from semi-industrialization and industrialization, which are based on partial and complete production of prefabricated wooden parts and elements, respectively. These elements are semi-finished and finished (off-site) in plants to be assembled at the construction site, as theoretically described by 15 and scientifically confirmed by 31.

In contrast to masonry markets, whose technique is supported only by a single typology with different finishing examples, wood-based houses should be singularly analyzed regarding their market costs, due to the attractive and technical attributes ensured by many structural concepts and standards of workmanship. According to 3, the best economy in timber construction is generally achieved when standard-size members can be utilized in a repetitive arrangement with simple connections. This is very important, as 32 verified that entrepreneurs should ensure the quality of the final product to be delivered on promised time intervals and with agreed-upon cost.

The overall construction cost corresponds to the minimum value attributed to a house, calculated from the basic unitary cost, which considers the full cost per square meter of a standard project 19.

In 1964, Decree 4591 established a unitary cost of construction to measure property costs 18, which became an indicator of sectoral cost over the years 33. These basic unitary costs do not consider the following: groundwater retraction, projects (structural and architectural), ovens and stoves, lifts, electronic devices (ventilation, exhaustion, heating, etc.), urbanization and recreation, landscaping, taxes, ground, among others 19. The estimation of basic unitary costs of timber-based houses becomes important, as this activity could be exploited and absorbed by the construction sector (regardless of the forest-timber industry), which was about 10% of the Brazilian Gross Domestic Product in 2015 34.

From this domestic scenario, this study aimed to evaluate the basic unitary costs of timber houses produced in Brazil for each housing technique while considering three main finishing standards and three types of production. This is justified by the pricing omission of timber-based techniques in different regional studies such as 35)-(37, among others. Thus, the following hypothesis is suggested: contrary to the impressions of Brazilians, timber houses may be economically competitive and, in some cases, cheaper than masonry buildings in the Brazilian market.

Methodology

To facilitate data collection, this study obtained, by means of a survey, an average sale value per timber housing technique, considering an average standard built area for the finishing standards described in Table I (low, average, and high).

A 100 m2 built-area, single-story house was set as a referential criterion. The average value of the built area was established by the admission of a medial and integer value.

This admitted built area of 100 m2 complied with the gradient indicated in 19, which prescribes that the average area of housing with the average finishing standard is 99,47 m2 in equivalent area, or 106,44 m2 in real area (Table I). Thereby, the sampled companies declared an average basic unitary cost for the house under consideration with regard to each available wood-based construction technique according to their finishing standards (low, average, and high) and their production processes (artisanal, semi-industrial, and industrial). The values obtained were compared to the basic unitary cost

of masonry houses using Brazilian Institute of Geography and Statistics data on finishing standards, as given by 38. This referential value details only artisanal masonry houses, which predominate locally. Data collection was carried out together with entrepreneurs from Brazilian timber house companies by means of a survey based on face-to-face interviews, following the methodology of 39. Using the Brazilian regulations, semi-structured questions were designed by the managing group and refined by academic and sectoral actors, which were then applied to each studied producer 39.

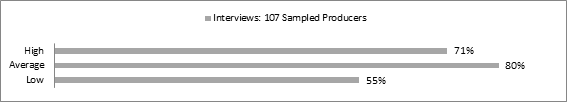

Two queries were analyzed in this paper. Of a quantitative nature and with open response, first question was “What is the cost range in US$/m2 for each timber house produced by your company?”. This query aimed to obtain basic unitary costs (minimum, average, and maximum), expressed in dollars per square meter of built area (US$/m2) and arranged according to production (artisanal, semi-industrial, and industrial) and finishing standards (popular, average, and high). The last evaluation was based on the second question: “What is(are) the type(s) of finishing standard(s) for timber houses offered by your company?”. This question was of qualitative and trichotomic nature and included three closed responses in order to verify the available finishing standards for timber houses (low, average, and high). Following the suggestion of 39, the qualitative responses of the second question were converted to percentages.

The number of timber housing producers located in Brazil was estimated by means of their official websites, since there was no official list. Survey sampling was performed from this population. This process was carried out in six states (São Paulo, Minas Gerais, Paraná, Rio Grande do Sul, Santa Catarina, and Distrito Federal), where most Brazilian timber housing producers are concentrated (specifically, 92% of the sector) 39.

All entrepreneurs from this wide regional population were contacted via phone calls, and they freely decided about their participation, evincing a random process as reported by 39.

Statistical analysis

In order to validate the representativeness of this sectoral survey, the margin of error was measured and compared to literature values. The Raosoft Sample Size Calculator software 40 was used, which prescribed values of 95% for the confidence level and 50% for the response distribution.

Results and discussion

Statistical analysis of the surveyed sample

While this study integrated a series of different approaches developed to characterize the timber housing production sector in Brazil, 16), (31), (39, and dozens of other approaches ascertained a domestic sectoral population of 210 producers, out of which 107 companies were randomly evaluated with a representative sampling rate of 51% and a margin of error of 6,65 %. This value is close to the ideal level of 5%prescribed by 41. Therefore, the costs presented in the next section may vary slightly by ±3,325% with respect to the margin of error for this sample.

Basic unitary costs of timber houses produced in Brazil

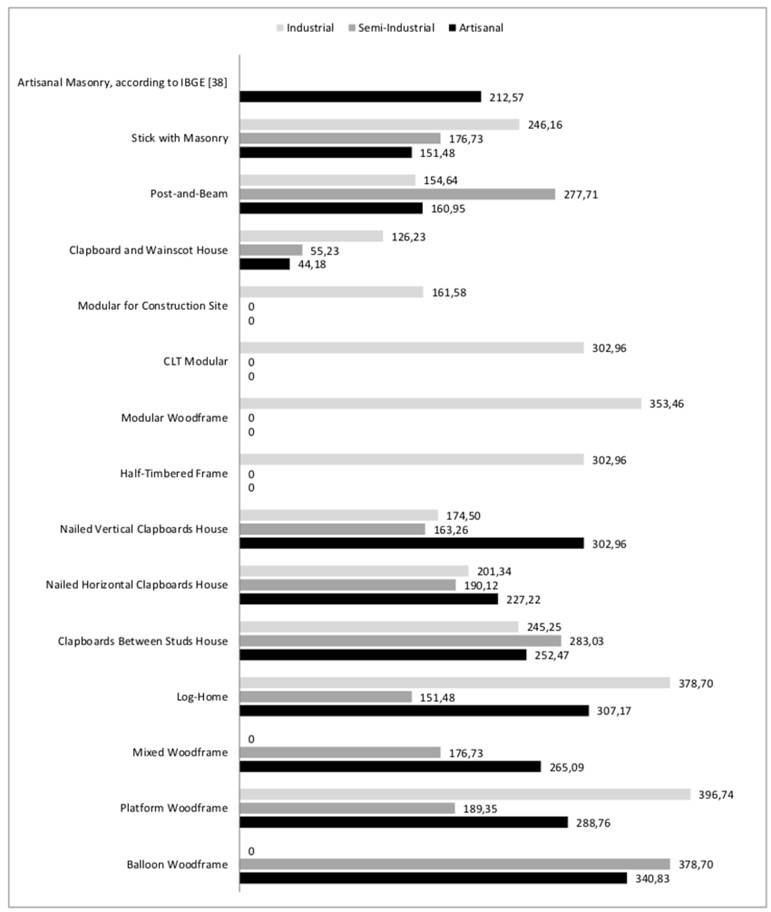

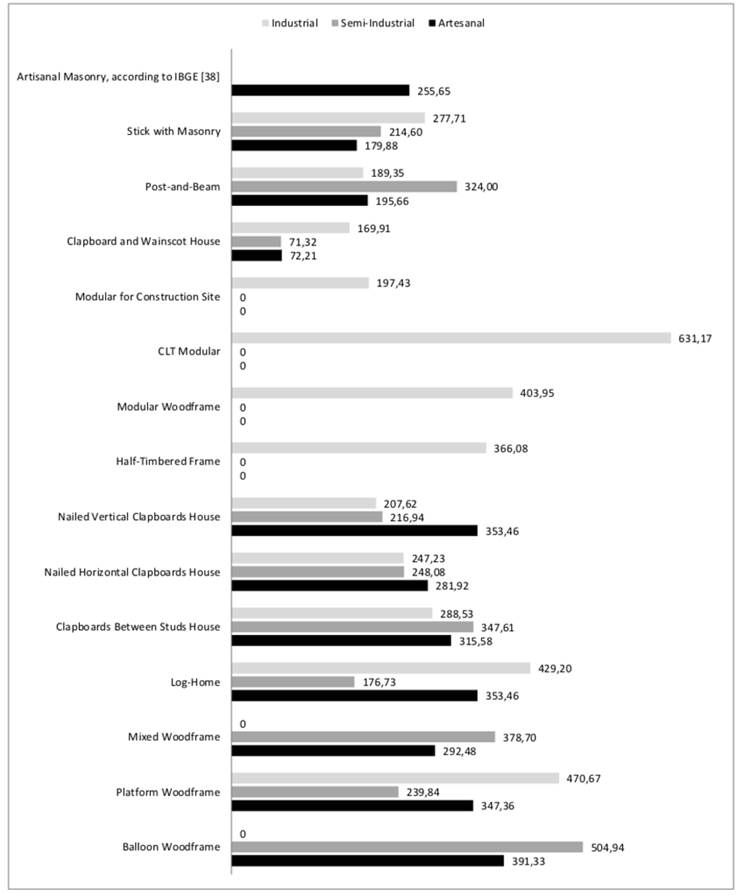

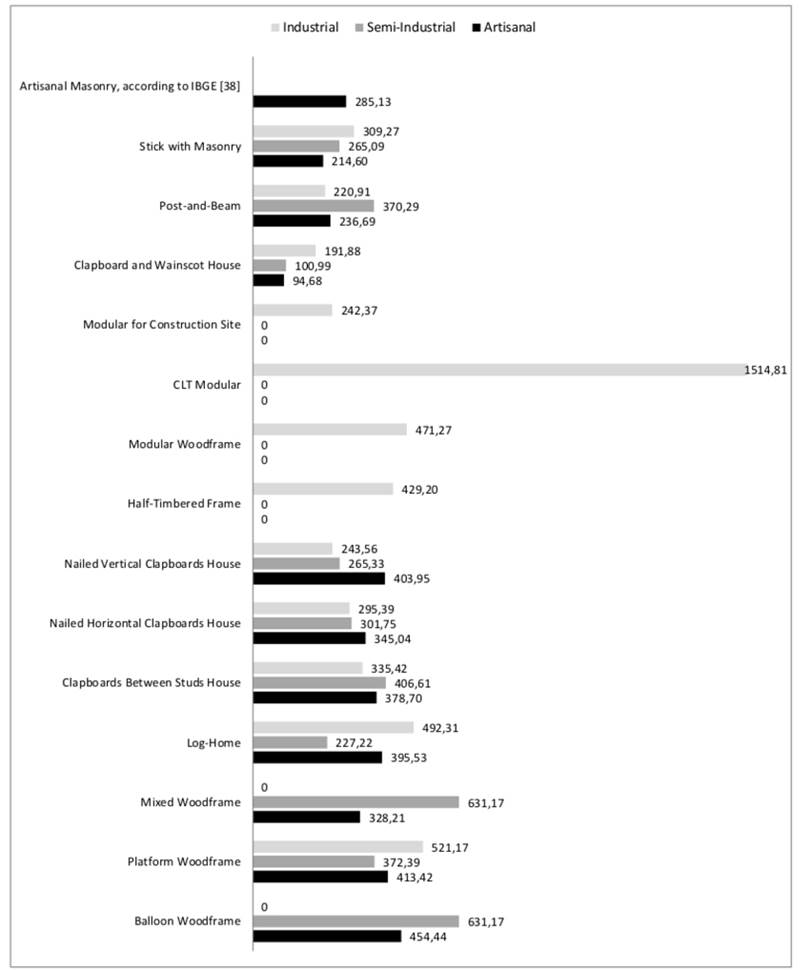

As Brazilian construction is widely dominated by structural masonry 30, this study inserted the correspondent basic unitary cost of artisanal masonry estimated by the Brazilian Institute of Geography and Statistics (IBGE) in all figures. The data of 38 considered the masonry costs for the macro-region under study. In view of the contrasts between masonry and timber houses, the outcomes regarding the basic unitary costs of each technique were organized under two parameters: production processes and workmanship standards. It is important to emphasize that an individual cost per technique is formed by a global fee that includes technology, raw material procurement and processing, parts production, and building assembly and finishing. To specify the sectoral results, the production techniques were grouped into three graphs for each finishing standard, according to the available processes: low (Fig. 1),medium (Fig. 2), and high (Fig. 3). The analysis of the basic unitary costs of timber housing produced in Brazil proved the studied hypothesis. Timber housing can be economically competitive with regard to masonry solutions, as there are timber techniques cheaper than this traditional method of bricks and concrete. This finding discredits Brazil’s popular perception about the higher costs of timber houses. Clap-board and wainscot housing with a low standard and an artisanal method was the cheapest technique (Fig. 1), and CLT modular housing with a high standard and an industrial process was the least viable model (Fig. 3).

Figure 1: Basic unitary cost (US$/m2) of timber houses with low finishing standard

Figure 2: Basic unitary cost (US$/m2) of timber houses with average finishing standard

Figure 3: Basic unitary cost (US$/m2) of timber houses with high finishing standards

For the low finishing standard (Fig. 1), 15 timber construction techniques demonstrated lower costs per built area than masonry housing: stick with masonry (in artisanal and semi-industrial production processes), post-and-beam (artisanal and industrial), modular for construction site (industrial), clapboard and wainscot (artisanal, semi-industrial, and industrial), nailed vertical and horizontal clapboard houses (both techniques in semi-industrial and industrial processes), log-home (semi-industrial), and mixed and platform woodframe houses (both varieties in semi-industrial processes). Apart from the platform and mixed woodframe varieties (which are modern, light, and efficient examples 15), (42), (43 and the post-and-beam technique, the general panorama found for the other wooden techniques matches some solutions with lower added-value and simpler technology. These exceptions were justified by their greater availabilities in the Brazilian market, as already stated by 16). In addition, 17 construction examples were more costly than masonry housing (Fig. 1): clapboards between studs (all three production processes), balloon and platform varieties of woodframe (artisanal and semi-industrial), loghomes (artisanal and industrial), vertical and horizontal varieties of nailed clapboard and mixed type of woodframe (all three techniques in artisanal production), post-and-beam (semi-industrial), and CLT modular, stick with masonry, woodframe modular, and half-timbered frame houses (all four techniques only in industrial production).

For the average standard (Fig. 2), 14 techniques were cheaper than masonry housing: clapboard and wainscot (all three production processes), stick with masonry (artisanal and industrial), platform woodframe and log-home (semi-industrial), modular house for construction site (industrial), and nailed vertical and horizontal clapboard varieties (semi-industrial and industrial). However, 18 varieties exceeded the cost of masonry: clapboards between studs (all production processes), stick with masonry (industrial), post-and-beam (semi-industrial), half-timbered frame, CLT and woodframe modular houses (all three techniques in industrial process), balloon and mixed woodframe varieties (artisanal and semi-industrial), nailed vertical and horizontal clapboards varieties (artisanal), and log-homes and platform woodframe (both techniques in artisanal and industrial processes).

Regarding the high finishing standard (Figure 3), 11 techniques revealed lower basic unitary costs than masonry housing: clapboard and wainscot (all three productions), stick with masonry (artisanal and semi-industrial), post-and-beam (artisanal and industrial), modular for construction site (industrial), nailed vertical clapboards (semi-industrial and industrial), and log-home (semi-industrial). However, 21 construction techniques were more expensive than masonry: nailed horizontal clapboards, clapboards between studs, and platform woodframe houses (all three techniques in all productions), post-and-beam (semi-industrial), nailed vertical clapboards (artisanal), log-home (artisanal and industrial), mixed and balloon woodframe varieties (artisanal and semi-industrial), and woodframe modular, CLT modular, stick with masonry, and half-timbered frame houses (industrial).

The clapboards between studs technique showed basic unitary costs higher than artisanal masonry housing (Figs. 2 and 3), which is explained by the frequent consumption of native woods involved in this technology, as confirmed by 15. The higher costs of native species reposition their products for noble uses 44, but timber from Brazilian native forests has higher costs due to complex transportation, as measured by 45. Given this condition, the clapboards between studs technique is usually aimed at finer uses in lodges, chalets, and holiday homes 46.

The clapboard and wainscot technique reported lower costs than masonry (Figs. 1 to 3). Popular in rural applications, this more viable situation was justified by the exclusive consumption of pine wood (whose silvicultural variety is cheaper than native species 44), (47), affordable access for low-income people 48, and better and simpler aesthetic, structural, and production features 49.

In these three contexts (Figs. 1 to 3), the half-timbered frame, woodframe modular, and CLT modular construction techniques showed basic unitary costs above those of artisanal masonry housing. Higher industrialization and customization of these examples resulted in factors that confirmed the higher costs expected. However, modular houses for the construction site, which features less refinement and intense industrial and commercial functions, were cheaper than masonry due to the excessive use of pine woods and large-scale production.

The stick with masonry technique showed a higher cost than masonry in industrial production, as well as lower costs in the artisanal and semi-industrial methods. Post-and-beam was cheaper than masonry in artisanal and industrial models, and it was costly in semi-industrial production (Figs. 1 to 3). Despite the simplicity and low technological evolution of these two techniques, their higher costs were related to the use of noble woods and the customization of singular projects 15).

Similar situations were observed for the nailed horizontal and vertical clapboards techniques (Figs. 1 to 3), as their artisanal processes were more costly than masonry, while their semi-industrial and industrial production models were relatively close. Greater rusticity and architectural simplicity justified these lower costs in industrial stages, while custom projects are more costly when produced manually.

The log-home technique showed a singular panorama: artisanal and industrial production models exhibited higher basic unitary costs in comparison to artisanal masonry(Figs. 1 to 3), while its semi-industrial process was cheaper. This scenario is due to the low presence of specific developers, despite the higher lumber and round-wood consumption.

Three varieties of woodframe technique (platform, balloon, and mixed) revealed higher costs in their artisanal processes than masonry. However, they were closer or slightly above the cost of masonry, both in semi-industrial and industrial models. The higher cost of woodframe could be attributed to the following factors: higher technological complexity 50), (51, high production efficiency 42), (43), (52, and the structural utilization of wooden composites and engineered products 52), (53. But these materials have reported higher market costs 54.

In fact, the modularization of timber construction was more costly than prefabrication in Brazil. As modern manufactures usually require more investment in technology and machinery for advanced production, this scenario is very plausible for the global progress and innovation in timber construction, despite the fact that lower longterm costs are expected for modular buildings. Even in Canada, where timber industry is widely known by its high technology, the modularization was marginally more cost-effective than panel prefabrication 55. Still, panel prefabrication could be productively updated using automation-based improvements, as analyzed by 56.

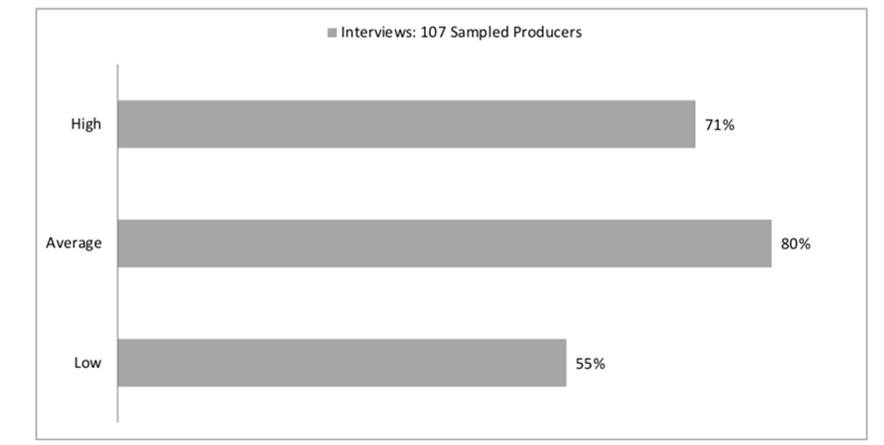

The results of the last question were described in Fig. 4. An important consideration is that the sampled companies could declare to offer one, two, or three finishing standards to supply any market demands. Regardless of the construction technique, this sector concentrates the supply of solutions with high and average finishing standards, focused on select markets and wealthy clients. Nevertheless, more than half of the studied sector offers low standards for popular use. The surveyed scenario showed that timber housing is diverse in Brazil because it is available to all economic classes.

Figure 4: Finishing standards available in the timber housing production sector

Most of the population is willing to pay slightly greater amounts of money for a higher-quality residence 57. In this scenario (Fig. 4), the average- and high-standard classes may hold current clients and also attract a considerable share of future buyers for timber houses, i.e., if benefits and economic viability were better exploited. In the perspective of popular houses involving lower standards and thus lower costs, the large-scale production of standardized timber houses becomes a way to offer dwelling with acceptable quality and uniform features. This is assured by 58, who confirmed that prefabricated buildings provide more environmental benefits than on-site construction, i.e., essentially in terms of waste generation, materials and energy consumption, and carbon emissions. Moreover, 59 argued that engineered wood products arise as promising solutions to increase the efficiency and sustainability of the innovative construction. Therefore, companies must adapt their culture and processes to society’s demands, since an innovative organization will undoubtedly generate long-term value and will be better prepared to deal with the economic, social, and environmental challenges looming in this century 60.

In general, when the construction of a green building is planned, it requires about 10% additional costs, yet it should offer more than 50% energy and water savings over its lifecycle 61. Design, materials, and tools are the factors that drive up costs in green projects 26. In timber housing, greener projects really add more value from an environmental perspective, since buildings are built with lignocellulosic bioproducts, are strongly designed by those principles, and have several advantages.

Conclusions

From a diversified sample formed by half of the Brazilian timber housing production sector, all timber construction techniques were classified in terms of housing production and finishing standard types, and their basic unitary costs were estimated. Each overall value was composed of a sum of fees related to technology, materials, parts production, construction assembly, and finishing process.

In view of the 96 possible varieties produced by the Brazilian production sector, about 42% of timber housing techniques showed basic unitary costs lower than those of artisanal masonry regarding three production processes and three workmanship standards. However, about 5% of samples revealed a slightly higher value, with basic unitary costs up to 10% above this non-sustainable technique based on concrete and bricks. Regarding basic unitary costs in dollars per square meter, it is concluded that almost half of timber-based residences produced in Brazil are competitive when compared to masonry houses.

Despite this unprecedented finding, which is very favorable for the domestic housing scenario, there is the need to associate it with the paradigm of many Brazilians, characterized by a still divergent cultural barrier on the use of timber construction. As an affirmative response to satisfying expectations and mitigating this outdated archetype, the rediscovery of timber houses may combine, both globally and domestically, the reinterpretations by famous architects on the utilization of traditional techniques and the contemporary examples led by engineering teams focused on intensive prefabrication of timber parts. The viable costs of different techniques shown by this sectoral survey alternatively represent a positive argument to be observed and considered by clients, since timber construction provides multiple environmental benefits related to low carbon emissions and intensive carbon fixation throughout the product’s lifecycle, as well as rational production with lower levels of waste generation and water use.

Despite the low popularity of timber housing in Brazil, the increase in this product’s consumption can be stimu- lated through diversified solutions and competitive costs, as identified in this research. The domestic market could foster the large-scale production of multiple cost-effective options for timber housing, both in current industrial facilities and future small-sized plants. Therefore, the competitive costs associated with the mass production of timber houses could directly contribute to the reduction of the housing deficit in Brazil, whose national demand exceeds 6 million residences 62. Hence, low-standard timber houses emerge as interesting choices for less privileged people.

From another market perspective, the greater participation of superior finishing options (high and average) for timber housing reinforce their status as solutions for select and wealthy clients and as secondary dwellings for leisure in specific regions, such as countryside, mountain, and coastal areas. This market can expand for more stringent clients attracted by sustainable features and singular aesthetics.

In light of the above, both simplified and sophisticated timber houses may offer competitive basic unitary costs compared to masonry-based examples, making timber housing more affordable and accessible for any social class in the Brazilian context.

It is necessary to continue this sectoral survey in other nations, as it is an effective tool to identify costs, as well as compare different moments for the Brazilian perspective, especially to update the costs per housing example for the next decades. In addition, the methodology and considerations of costs per technique according to different production processes and finishing types may be used for other construction techniques based on traditional non-wood materials, e.g., steel, stone, concrete, and bricks. Consequently, further research may develop studies using this methodology and its outcomes for other scopes, e.g., production and corporative costs in every stage from a specific developer according to its characteristics and peculiarities (technique, finishing standard, and production types). This could even include case studies to evaluate additional components such as environmental and social costs and lifecycles from design to development of different timber housing techniques.

There is also the need to estimate the global environmental costs for all timber housing techniques. Thus, deeper analyses per construction technique are required to evaluate its complete lifecycle, as well as the environmental costs and profits caused by the complex decisions involved in construction design and development. However, developing an alternative estimation method will be required to satisfy the evaluation of economic components for detailed environmental analyses, since the measurement of basic unitary costs disregards architectural and structural projects, gardening and recreation, and the use of sustainable electronic devices (ventilation, exhaustion, heating, lifting, etc.).

Due to the large number of components to be considered in these complex environmental analyses, the authors recommend conducting specific case studies aimed at the characterization of each construction technique, since each timber-based example has different levels regarding architectural characteristics and details, construction technologies, and production systems.

References

License

Copyright (c) 2022 Victor Almeida De Araujo, Francisco Vasconcelos De Araujo, Juliano Souza Vasconcelos, Maristela Gava, André Luis Christoforo, José Nivaldo Garcia

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

From the edition of the V23N3 of year 2018 forward, the Creative Commons License "Attribution-Non-Commercial - No Derivative Works " is changed to the following:

Attribution - Non-Commercial - Share the same: this license allows others to distribute, remix, retouch, and create from your work in a non-commercial way, as long as they give you credit and license their new creations under the same conditions.

2.jpg)