DOI:

https://doi.org/10.14483/23448393.19517Published:

2023-10-17Issue:

Vol. 28 No. 3 (2023): September-DecemberSection:

Civil and Environmental EngineeringComparative Analysis of the Use of Nanosilica and Fly Ash in Hydraulic Concrete

Análisis comparativo del uso de nanosílice y ceniza volante en el concreto hidráulico

Keywords:

concrete, nanosilica, fly ash, strength (en).Keywords:

concreto, nanosílice, cenizas volantes, resistencia (es).Downloads

References

S.W.M. Supit and F.U.A. Shaikh, "Durability properties of high volume fly ash concrete containing nano-silica," Mater. Struct., vol. 48, 2015. [Online]. Available: https://doi.org/10.1617/s11527-014-0329-0. DOI: https://doi.org/10.1617/s11527-014-0329-0

J. Saloma et al., "Improvement of Concrete Durability by Nanomaterials," Procedia Eng., vol. 125, pp. 608-612, 2015. [Online]. Available: https://doi.org/10.1016/j.proeng.2015.11.078. DOI: https://doi.org/10.1016/j.proeng.2015.11.078

A. Suzuki and G. Sundararajan, "Deposition of Titania Nanoparticles on the Surface of Acid Treated Multiwalled Carbon Nanotubes Advanced Materials for Sustainable Development," Mater. Sci. Eng., Jun. 2010. [Online]. Available: https://doi.org/10.4028/www.scientific.net/AMR.117.27. DOI: https://doi.org/10.4028/www.scientific.net/AMR.117.27

S. Hernández, "Vida útil en el diseño sustentable de edificios, Teoría y Práctica," Ed. Trillas, 2015.

P. Pacheco-Torgal et al., "Nanoparticles for high performance concrete (HPC1)," Woodhead Publishing Series in Civil and Structural Engineering, Nanotechnology in Eco-efficient Construction, 2013. [Online]. Available: https://doi.org/10.1533/9780857098832.1.38 DOI: https://doi.org/10.1533/9780857098832.1.38

J.-Y. Shih, T.-P. Chang, and T.-C. Hsiao, "Effect of nanosilica on characterization of Portland cement composite," Mater. Sci. Eng., vol. 424, no. 1-2, pp. 266-274, 2006. [Online]. Available: https://doi.org/10.1016/j.msea.2006.03.010 DOI: https://doi.org/10.1016/j.msea.2006.03.010

S. Hernández, "Nano materiales con aplicación en arquitectura y construcción," Mc Graw Hill, 2021.

"¿Qué es la nanotecnología?" Vida Inteligente. [Online]. Available: https://www.euroresidentes.com/futuro/nanotecnologia/nanotecnologia_que_es.htm.

H. Biricik and N. Sarier, "Comparative study of the characteristic of Nano Silica, Silica Fume and Fly ash, incorporated cement Morters," Mater. Res., vol. 3, pp. 579, Dec. 2013. [Online]. Available: http://doi.org/10.1590/S1516-14392014005000054 DOI: https://doi.org/10.1590/S1516-14392014005000054

M. T., M. Moonis Z., and A. B., "Effect of nano-silica on mechanical, microstructural and durability properties of cement-based materials," J. Build. Eng., vol. 65, 2023. [Online]. Available: https://doi.org/10.1016/j.jobe.2022.105676 DOI: https://doi.org/10.1016/j.jobe.2022.105676

M. J., "Nanomaterials - the driving force," Mater. Today, vol. 7, no. 12, pp. 20-29, 2004. [Online]. Available: https://doi.org/10.1016/S1369-7021(04)00627-3 DOI: https://doi.org/10.1016/S1369-7021(04)00627-3

Mexican-Standard-NMX-C-414-ONNCCE-2017. Building industry, hydraulic cement, specifications and test methods. Washington (DC): National Organization for Normalization and Certification of Building and Edification, 2017, p. 17. [in Spanish].

C. Díaz, "Real Academia Española (RAE)-Asociación de Academias de la Lengua Española (ASALE): Ortografía de la lengua española», Onom, n.º 24, pp. 403–309, dic. 2011. [Online]. Available: https://doi.org/10.7764/onomazein.24.18 DOI: https://doi.org/10.7764/onomazein.24.18

"Atomic Layer Deposited (ALD) TiO2 on Fibrous Nano-Silica (KCC-1) for Photocatalysis: Nanoparticle Formation and Size Quantization Effect," Laboratory of Material Surface Engineereing and Nanofabrications, 2017. [Online]. Available: https://doi.org/10.1021/acscatal.6b00418.s001 DOI: https://doi.org/10.1021/acscatal.6b00418.s001

"Nanotecnología en el concreto," Nanosílice: aditivo superplastificante, Junio 2010. [Online]. Available: http://nanosilice.blogspot.com

F. Althoey et al., "Impact of Nano-silica on the hydration, strength, durability, and microstructural properties of concrete: A state-of-the-art review," Case Studies in Construction Materials, vol. 18, 2023. [Online]. Available: https://doi.org/10.1016/j.cscm.2023.e01997 DOI: https://doi.org/10.1016/j.cscm.2023.e01997

M. Garrido, "Modificación estructural del Gel C-S-H irradiado con láser continúo de CO2," Tesis Doctoral de la Facultad de Ciencias Químicas Universidad Complutense de Madrid, Madrid, 2018. [Online]. Available: https://dialnet.unirioja.es/servlet/tesis?codigo=230002

R. Guzmán, "El uso de Nanotubos de Carbono en el Concreto para mejorar su desempeño y durabilidad," Universidad Nacional Autónoma de México, Cd. México. Tesis digitales, 2012. [Online]. Available: https://es.studenta.com/content/110942884/el-uso-de-nanotubos-de-carbono-en-el-concreto-para-mejorar-su-desempeno-y-durabi

Chuzón Villacorta et al., "Diseño de concreto f´c= 210 kg/cm2 adicionado con Nanosílice para mejorar su resistencia a la compresión, Tarapoto 2020," Universidad César Vallejo. Repositorio Digital Institucional. [Online]. Available: https://hdl.handle.net/20.500.12692/59055

"Luminakret nanotecnología. Mejores materiales sustentables para la construcción," 2017. [Online]. Available: https://luminakret-nanotecnologia.ueniweb.com/#about_us

"Las trampas del carbón; Informe sobre las Centrales térmicas de Cárbon en España," Greenpeace.es, septiembre 2015. [Online]. Available: http://archivo-es.greenpeace.org/espana/Global/espana/2015/Report/cambio-climatico/las-trampas-del-carbon.pdf

M. Espinosa et al., "Análisis del comportamiento de los lixiviados generados en un vertedero de residuos sólidos municipales en la ciudad de la Habana," Rev. Int. Contaminación Ambientas, vol. 26, no. 4, Ciudad de México, 2010. [Online]. Available: https://www.scielo.org.mx/scielo.php?script=sci_arttext&pid=S0188-49992010000400006

C. Aire and L. Aguilar, "Ensayos de control del concreto lanzado con fibras en el túnel de la línea 12 del metro de la CDMX," XVII Congreso de Control de Calidad en la Construcción, CONPAT Chiapas, 2019. [Online]. Available: https://doi.org/10.21041/conpat2019/v1cc353 DOI: https://doi.org/10.21041/CONPAT2019/V1CC353

J. Byron and Vázquez, "Estudio de Hormigones de altas prestaciones utilizando áridos y cemento local, cenizas volcánicas naturales y súper- plastificante," Universidad de Cuenca, Facultas de Ingeniería, España, octubre 2010. [Online]. Available: http://dspace.ucuenca.edu.ec/handle/123456789/727

L. Espinoza and I. Escalante, "Comparación de las propiedades del concreto utilizando escoria de alto horno como reemplazo parcial y total del cemento Pórtland ordinario," Nexo Rev. Cient, vol. 21, no. 01, pp. 11-18, 2008. [Online]. Available: https://doi.org/10.5377/nexo.v21i01.405 DOI: https://doi.org/10.5377/nexo.v21i01.405

P. Caballero et al., "Optimización del concreto mediante la adición de nanosílice, empleando agregados de la cantera añashuayco de arequipa," Rev. Ing. Constr., vol. 36, no. 1, Perú, Apr. 2021. [Online]. Available: http://dx.doi.org/10.4067/S0718-50732021000100071 DOI: https://doi.org/10.4067/S0718-50732021000100071

S. Huaquiato and G. Belizario, "Utilización de la ceniza volante en la dosificación del concreto como sustituto del cemento," Revista de Investigación Altoandina – Rev. Investig. Altoandin, vol. 20, no. 2, 2018. [Online]. Available: https://doi.org/10.18271/ria.2018.366

K. Sobolev, "Effect of complex admixtures on cement properties and the development of a test procedure for the evaluation of high-strength cements," Advances in Cement Research, 2003. DOI: https://doi.org/10.1680/adcr.15.2.67.36726

J.C. Arteaga-Arcos et al., "The usage of ultra-fine cement as an admixture to increase the compressive strength of Portland cement mortars," Constr Build Mater., vol. 42, pp. 153, 2013. [Online]. Available: https://doi.org/10.1016/j.conbuildmat.2013.01.017 DOI: https://doi.org/10.1016/j.conbuildmat.2013.01.017

American Concrete Institute, "ACI PRC-121-08 Guide for concrete Construction Quality System in Conformance with ISO9001," 2008.

"Calidad del concreto hidráulico," N-CMT-2-02-005/04. [Online]. Available: https://normas.imt.mx/normativa/n-cmt-2-02-005-04.pdf.

P. Abhilash et al., "Effect of nano-silica in concrete; a review," Constr Build Mater., vol. 278, 2021. [Online]. Available: https://doi.org/10.1016/j.conbuildmat.2021.122347 DOI: https://doi.org/10.1016/j.conbuildmat.2021.122347

S. Huaquiato and G. Belizario, "Utilización de la ceniza volante en la dosificación del concreto como sustituto del cemento," Rev. de Investigaciñon Altoandinas - Rev. Investig. Altoandin, vol. 20, no. 2, 2018. [Online]. Available: https://doi.org/10.18271/ria.2018.366 DOI: https://doi.org/10.18271/ria.2018.366

H. Anda, "Instituto Tecnológico y de Estudios Superiores de Occidente, Sonora, Mex," Materia; Mecánica de Solidos. Obtenido de StuDocu, "Cabeceo con morteros de azufre de especímenes cilíndricos de concreto," Laboratorio experimental del departamento de Ingeniería civil y minas, 2024. [Online]. Available: https://www.studocu.com/es-mx/document/instituto-tecnologico-y-de-estudios-superiores-de-occidente/mecanica-de-solidos/cabeceo-con-mortero-de-azufre/7564337

P. Zhang et al., "Nanoparticle-reinforced building materials with applications in Civil engineering," Adv. Mech. Eng., vol. 12, 2014. [Online]. Available: https://doi.org/10.1177/1687814020965438 DOI: https://doi.org/10.1177/1687814020965438

M.R. Arefi and S. Rezaei-Zarchi, "Synthesis of Zinc Oxide Nanoparticles and Their Effect on the Compressive Strength and Setting Time of Self-Compacted Concrete Paste as Cementitious Composites," International Journal of Molecular Sciences, vol. 13, no. 4, 2012. [Online]. Available: https://doi.org/10.3390/ijms13044340 DOI: https://doi.org/10.3390/ijms13044340

How to Cite

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Download Citation

Recibido: 15 de junio de 2022; Revisión recibida: 27 de marzo de 2023; Aceptado: 26 de mayo de 2023

Abstract

Context:

Nowadays, nanomaterials constitute an innovative alternative for the construction sector. This study evaluates the benefits of adding nanosilica and fly ash to Portland cement concrete in terms of its mechanical strength properties.

Method:

45 specimens were used to compare the compressive strength and durability of concrete mixtures with nanosilica and fly ash. The specimens were studied after 7, 14, and 21 days to determine their maximum resistance.

Results:

The addition of small amounts of nanosilica (up to 1 %) significantly improved the compressive strength of the concrete. In contrast, a large amount of fly ash (up to 8 %) was required for a noticeable effect.

Conclusions:

Concrete with nanosilica yielded the best results in terms of mechanical strength. The key to improving concrete through nanosilica and fly ash is to reduce the water-to-cement ratio using chemical agents that reduce porosity and increase resistance.

Keywords:

concrete, nanosilica, fly ash, strength.Resumen

Contexto:

Hoy en día, los nanomateriales representan una alternativa innovadora para el sector de la construcción. Este estudio evalúa los beneficios de añadir nanosilice y ceniza volante al concreto de cemento Portland en función de sus propiedades de su resistencia mecánica.

Metodo:

Se utilizaron 45 especímenes para comparar la resistencia a la compresión y la durabilidad de mezclas de concreto con nanosilice y ceniza volante. Los especímenes fueron estudiados a los 7, 14 y 21 dias para determinar su máxima resistencia.

Resultados:

La adición de cantidades pequeñas de nanosilice (hasta 1 %) mejoraron significativamente la resistencia a la compresión del concreto. En contrate, se necesitó una gran cantidad de ceniza volante (hasta 8 %) para lograr un efecto notable.

Conclusiones:

El concreto con nanosilice dio los mejores resultados en cuanto a resistencia mecánica. La clave para mejorar el concreto con nanosilice y ceniza volante es reducir la relación cemento-agua utilizando agentes químicos que reduzcan la porosidad y aumenten la resistencia.

Palabras clave:

concreto, nanosilice, cenizas volantes, resistencia.Introduction

Concrete is currently the most widely used material in the construction industry. Therefore, research is being conducted with the aim of improving its physical properties and reducing its environmental impact. In recent years, studies and applications involving concrete have intensified in order to increase its strength and prevent cracking or micro-fissures occurring throughout the curing process via innovative materials such as nanotechnology and the utilization of supplementary cementitious materials (e.g., fly ash), which have played an important role in this regard 1.

Improving the performance of concrete is important for two reasons. Firstly, the demand for construction products and services is increasing as the world population grows. Portland cement, the essential concrete binder, accounts for nearly 80% of concrete-related CO2, emissions, as well as 5-7% of the global CO2, emissions 2. Secondly, the construction sector is one of the most polluting industries 3. However, it also produces the greatest economic wealth, progress, and social welfare around the world 4. Therefore, a balance is required to continue building without significant negative effects on the environment. 5 reported that as much as 50% of reinforced steel use could be reduced by increasing concrete’s compressive strength. Durable and high strength concrete is the main concern in future production as far material and eco-efficiencies are concerned.

Nanotechnology has begun to gain importance in this research area. Nanoparticles and nanosilica are commonly used to reinforce polymers and increase their hardness, modulus of elasticity, weatherability, flammability, etc. 6. In architecture and construction, the applications of nanotechnology range from improving the traditional mechanical properties of concrete to improved products such as paints, sealants, and glasses (to make them repellent against bacteria and other harmful biological agents). Nanotechnology has also shown its usefulness in improving the termal and strength properties of materials, among other benefits 7.

Nanotechnology is the study, design, creation, synthesis, manipulation, and application of materials, devices, and functional systems through the control of matter at the nanoscale, as well as the utilization of phenomena and properties related to it 8. The application of nanoparticles to enhance the durability and mechanical properties of cementitious composites was explored in the report issued by the RILEM Technical Committee (197, Nanotechnology in Construction Materials, TC 197-NCM) 9.

This type of technology faces various challenges in the construction sector. The fact that it handles submicrometric dimensions, which are imperceptible to the human eye, makes it intangible for industry professionals. However, its impact on the physical properties of a wide variety of everyday objects has been found to be so significant that it can modify the human experience in the construction industry. Since concrete is composed of various materials, it is crucial to know the chemical and physical properties of its materials before mixing them. The hardened properties of concrete are governed by many factors, such as chemical properties, physical properties, the water-to-cement ratio, cement contents, cement type, and quality control during production, among others 10.

The technical literature highlights the benefits of combining ordinary Portland cement (OPC) with nanomaterials such as nanosilica. 11 demonstrated that the compressive strength developed by OPC mortars containing nanosilica particles was considerably better than that obtained with fly ash. In Mexico, it is not common to use OPC; the commercially available cements are the so-called Composite Portland Cement (CPC). These CPCs contain supplementary cementitious materials added in different proportions, as per NMX-C-414-0NNCCE-2017 12. The objective of this research was to verify whether the previously reported benefits of utilizing nanomaterials on OPC are valid for concrete elaborated with CPC.

Thus, in the following paragraphs, we will first describe what nanosilica is and its properties, highlighting the way it contributes to improving the concrete mix. Then, we will do the same with fly ash. Once both nanomaterials have been presented, we will describe the methodology used to carry out some laboratory tests. Then, we will outline the experimental results, discuss the main findings, and, finally, present some recommendations and conclusions derived from this research.

Nanosilica

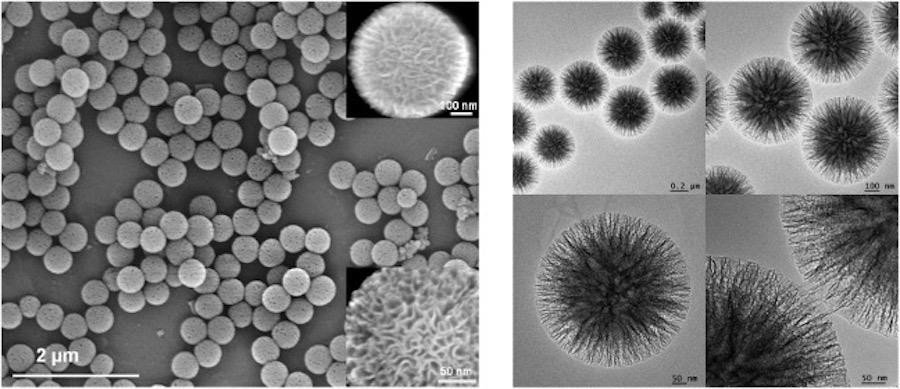

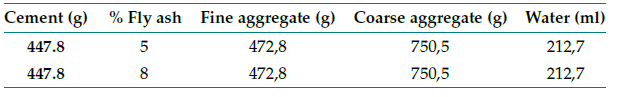

Silica is a compound composed of silicon and oxygen, which is present in some materials such as quartz or opal 13. Its chemical formula is SiO2. On a smaller scale, nanosilica consists of nanoparticles with a uniform size ranging from 250 to 450 nm in diameter. Nanosilica has two surfaces: external and internal (pores). A large external surface area allows it to adequately fill the voids that exist in a concrete mix 14. Fig. 1 shows the structure of nanosilica, with the outer surface of the sphere surrounding the nanosilica particle and the internal pores visible, demonstrating that it is not a compact material.

Figure 1: Structure of nanosilica particles (14)

Nanosilica has a fibrous morphology. Therefore, it has good thermal and hydrothermal resistance, as well as a high mechanical stability. This is due to the fact that its particles have dendrimeric fibers (in the form of angles arranged in three dimensions to form spheres), thus allowing easy access to the surface. It has been found that, by adding nanosilica, concrete acquires the following properties 15:

-

Greater plasticizing and water reducing power

-

Increased mechanical strength at initial and final ages

-

Reduced permeability and increased durability

-

The ability to prevent segregation and excessive exudation

-

Improved finish and surface textura

One of the most important mechanical properties of cement paste is its tensile strength, which directly affects cracking due to shrinkage. If the cement paste has a low tensile strength, the cracking may be greater, and it can affect the durability of the structure. Nanosilica can help to reduce the harmful pores and permeability, as well as to increase the strength of the calcium-silicate-hydrate (C-S-H), thus optimizing the durability and mechanical properties of concrete 16. The use of nanosilica is beneficial to reducing the presence of cracks.

To better understand the existence of cracks, it is essential to note that there are two types of pores within the microstructure of cement paste. Firstly, there are gel pores with diameters <10 nm, which are considered part of the C-S-H triad, where C refers to CaO (calcium oxide), S corresponds to SiO2 (silicon dioxide), and H refers to H2O (water). Secondly, there are capillary pores ranging from 10 nm to 10 μm17. The water that is not consumed in the hydration process is generally stored in these pores, which weakens the concrete, as there are no bonds with the hydrated calcium silicate 18. Air inclusions and void spaces may also occur where the paste does not consolidate correctly. To achieve quality concrete, the addition of nanosilica and ash admixtures, as well as the spaces between them, must be covered with paste. Therefore, the production process should have the appropriate conditions and undergo quality controls. The water-to-cement ratio is a fundamental factor to increase or decrease compressive strength, permeability, and resistance to weathering 19.

The main purpose of improving materials using nanomaterials is to reduce structures’ costs of construction and maintenance, to speed up construction times, and to ensure the desired performance. It also aims to improve the physical and chemical characteristics of materials for various purposes.

To illustrate the practical use of the presented concepts, we could name an example. In Mexico, the Luminaket Polyamide Concrete company, founded by architect Jesus Cervantes Herrera, incorporates nanobots (metallic semiconductors) into hydraulic concrete. When in contact with sunlight, a chemical reaction takes place which reduces pollution, global warming, and acid rain in large metropolises 20.

Before proceeding with the description of fly ash, some general points should be summarized. From an engineering point of view, the complex cement-based structure at the nanoscale is evolving, aiming for stronger and more durable concrete. These new materials have better properties, such as electrical conductivity and less moisture absorption. Therefore, nanosilica concrete constitutes an innovation in the development of new construction materials.

Fly ash

The thermoelectric industry, like the construction sector, has recently experienced significant growth. However, this growth has resulted in the overexploitation of resources, particularly coal, which is one of the primary fuels used. The burning of coal generates millions of tons of waste containing toxic levels of heavy metals and minerals, most of which end up in landfills, posing a threat to health and the environment 21. Large amounts of fly ash and slag are discarded every minute due to the high consumption of coal in combustion processes, with between 80 and 250 kg of waste obtained from one ton of coal 22.

The use of fly ash in concrete, much like nanosilica, improves its mechanical properties due to the granulometry, size, distribution, shape, and texture of the particles. These effects reduce wáter consumption in fly ash concrete mixes 23. Fly ash is used in concrete worldwide to modify the properties of fresh and hardened concrete, and it is an environmentally friendly solution, as it is an industrial byproduct from thermoelectric plants. The physical properties and chemical composition of fly ash vary depending on the coal and the power plant. Fly ash is classified by its CaO (calcium oxide) content, with those having less than 10% being classified as low calcium oxide fly ash and those with more than 10% as high calcium oxide fly ash 24.

Fly ash is primarily pozzolanic. This makes it highly binding and is derived from its ability to react with calcium hydroxide, forming hydraulic compounds similar to those generated during the clinker hydration of cement (after calcining limestone and clay, i.e., a hydraulic binder). The pozzolanic reaction produces less porosity in the cement paste, making it more durable and stronger. It also increases impermeability and steel strength against corrosion 25. These benefits make fly ash an ideal component in concrete to enhance firmness and durability while recycling and reusing industrial waste. Cement with a pozzolanic aggregate such as fly ash offers several advantages. For example, the aluminosilicates present in the pozzolan react with the calcium hydroxide released in the hydration of Portland cement, which is a slow reaction (thus reducing heat); consumes calcium hydroxide, improving resistance to acid environments; and fills the spaces resulting from the hydration reaction of the cement, increasing impermeability and mechanical strength 26.

The addition of fly ash to concrete provides several benefits, including reducing the water demand in the mix and decreasing the energy consumption and CO2 emissions associated with cement production 27. The key to improving concrete lies in its cementitious base, which combines with other materials such as coarse aggregates and continuous reinforcements, such as reinforcing Steel rods or dispersed reinforcements (e.g., short fibers of different materials). Therefore, the cementitious base or bond matrix is of the utmost importance in improving concrete properties (i.e., mechanical properties) 28.

The potential applications of nanomaterials and the economic impacts they generate open up different possibilities, such as a new generation of concrete and the development of materials that comply with current regulations with a lower environmental impact. In short, the use of fly ash and nanosilica helps reduce the energy consumption and CO2 emissions associated with cement production. However, currently, fly ash is only used in Mexico for landfill purposes, but it has great potential to improve materials in the construction industry.

It is important to note that the use of concrete with these admixtures may not immediately solve the environmental problem, but it demonstrates the potential to create functional materials that may help improve spaces both visually and functionally.

Methodology

It has been reported in the literature that the addition of nanosilica to concrete can accelerate the hydration process and reduce the use of cement, resulting in more resistant nanocomposites with better mechanical properties. Laboratory strength tests have confirmed that the resulting materials have superior properties when compared to the existing ones. The use of nanomaterials aims to ensure free links at the nano level, which can generate strong bonds between the cement matrix and other materials, resulting in increased strength and improved curing properties.

CPC, as specified by the NMX-C-414-0NNCCE-2017 Mexican standard 12, is a combination of Portland cement clinker, calcium sulfate, and a mix of pozzolanic materials, which are, in essence, reactive silicon dioxide (SiO2) and aluminum oxide (Al2O3), blast furnace slag, and/or limestone. This type of cement is comparable with European Portland-composite cement CEM II/B-M, according to the EN 197-1 standard 29.

In this research, laboratory tests were conducted to validate the effectiveness of using nanosilica in concrete. Two types of variables were considered, dependent and independent, with the former referring to compressive strength and durability and the latter to proportional design for the hydraulic concrete mix, the water ratio, the granulometry of the coarse aggregate, and durability, as evaluated with the ACI-522R 30. Sampling methods and materials testing were conducted according to N-CMT2-02-005 31.

The laboratory tests aimed to compare the compressive strength and durability of the cement mixture with nanosilica and fly ash. The results help to determine which of the two aggregates reacts better with cement, ultimately resulting in the production of an innovative material. The tests performed are outlined below.

Laboratory tests (procedure)

Taking the aforementioned standards as a reference, different experiments were carried out in the laboratory of Universidad Autonoma del Estado de Mexico’s Faculty of Engineering. The steps considered in the process were the following:

-

The molds were made of stainless steel, as a non-absorbent material was required which did not react with the cement. Before using the molds, they were covered with mineral oil. The size of each cylinder was 15 cm in diameter by 30 cm in height (Fig. 2).

Figure 2: Molds used to make the specimens

-

The mixture was made with each ingredient previously weighed. Fig. 3 shows how the mixtures were generated, as well as their physical appearance before being poured into their corresponding molds. The cement used was commercially available CPC

Figure 3: Concrete with fly ash (left) and nanosilica in concrete (right)

River or mine sand was also used. The 200 mesh fines were removed, and nanosilica and fly ash were added. This was done to understand their function and real application in the construction industry.

-

The mixtures were added to the containers and vibrated with a rod to remove the air from the mixture. Subsequently, they were poured into the corresponding molds to generate standard size cylinders for strength and durability testing (Fig. 4).

Figure 4: Pouring the concrete mixture into the molds

-

Finally, several cylinders were made, which were used to perform the experiments. They are shown in Fig. 5

Figure 5: Molds in the drying process

Once the cylinders were generated, they were allowed to dry in pairs. For the first pair, the process took seven days; for the second, 14 days; and the last one was left to dry for 28 days. The tests performed on the samples are described later in this document.

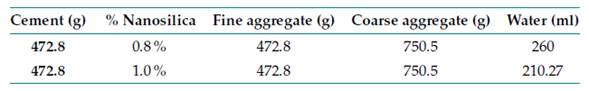

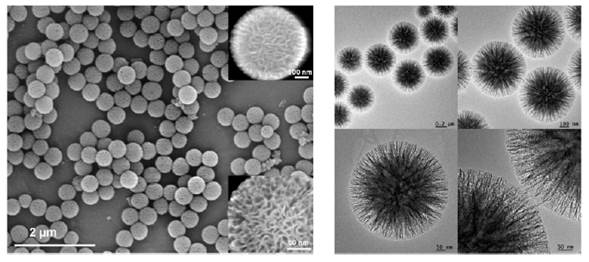

Before presenting the laboratory tests, the process followed for the preparation of the mixtures is described. Table I summarizes the proportions used to produce the cylinders that would later be subjected to compression tests. The amount of nanosilica and water used in the compositions was varied.

Table I: Proportion of the concrete mix with nanosilica

For the mixture of hydraulic concrete and nanosilica, the ratio of cement and sand was 1:1. Regarding the amount of nanosilica, 0,8 and 1% were used in order to determine the amount that yielded the best resistance results. These quantities of nanosilica were taken from 32, a recent research work that recommends a dosage between 0,6 and 1% of nanosilica admixture in concrete. The compressive strength tests of the specimens were carried out for materials of 7, 14, and 28 days of age.

For the desired comparison, the same was done with the other material of interest; for the case of concrete with fly ash aggregate, the mix design is presented in Table II. Here, only the proportion of fly ash was varied, leaving the other variables constant, including the amount of water.

Table II: Proportion of the concrete mix with fly ash

The amount of fly ash used was determined from 26, whose authors recommend the use of fly ash as a substitute for cement in a range from 2,5 to 10 %, taking into account that, from 10% onward, the strength value of concrete decreases 33.

For this work, proportions of 5 and 8% were used to obtain an adequate strength.

To carry out the laboratory tests in an orderly and systematic manner, in order for them to be replicated by interested readers, the sampling and material testing methods established in the N-CMT2-02-005 were used. The steps described below were followed.

-

24 hours after casting, the samples were demolded and water-stored until test time. The curing of the samples was carried out at room temperature (25 °C).

-

The specimens were labeled with their characteristics. Immediately afterwards, a sulfur cap was placed on them so that the face was completely smooth and showed no anomalies at the time of carrying out the strength test. Figs. 6-9 show the steps of this first stage in the preparation process

Figure 6: Demolded and labeled specimens

Figure 7: Arrangement of specimens prior to placement of sulfur

Figure 8: Placement of sulfur

Figure 9: Specimen ready for resistance tests

-

The samples were then tested in the compression machine (PILOT, Controls) to collect data allowing to understand the behavior of the materials. Figs. 10 and 11 present both the testing machine and the way in which the results were generated. Fig. 12 shows the fractured specimen after being subjected to the compression test

The next section summarizes the results obtained.

Figure 10: Compressive strength testing machine

Figure 11: Graphic results provided by the compressive strength testing machine

Figure 12: Fractured specimen after being subjected to the strength test

Results and discusión

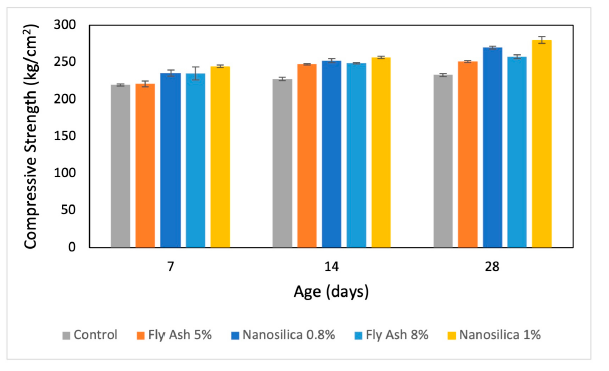

Adding nanosilica significantly improves concrete’s compressive strength properties. Its use is economical since it requires small amounts, and a good performance is very feasible. In the admixture, it favors the durability of concrete. Fig. 13 shows the strengths obtained at 7, 14, and 28 days for the two types of mix used. As can be seen, the values range between 230 and 280 kg/cm2.

Figure 13: Compressive strength

It was found that a nanosilica-based admixture can reduce the use of water by up to 24% (Table I). This confirms that, by adding nanomaterials to concrete, the mixture is integrated by filling the spaces that are generated during the hydration process.

Thus, it can be stated that the use of nanosilica greatly influences the strength of concrete. The difference in the amounts of nanosilica used in the mixtures is minimal (just 0,2 %). Therefore, it is necessary to carry out more tests in the future, using larger amounts of this material and aiming to obtain greater resistance. It is important to point out that, during the curing process of the concrete mixture, the specimen was compacted, accelerating the hydration process. The setting time decreased because the nanoparticles’ hydration reaction is faster than that of the concrete 34.

As for fly ash, a similar behavior was observed Fig. 13 shows the resistances of the tested specimens over time. The observed range now varies from 215 to 255 kg/cm2. In the case of nanosilica, the increase in resistance is constant; fly ash tends to have less increase.

Thus, it is verified that the use of fly ash in the concrete mixture produces a slower increase in resistance. However, the resistances are suitable for use in light traffic pavements.

Fig. 13 shows the strengths obtained for both aggregates.

It is important to note that there is no big difference in the results, although the concrete with nanosilica shows higher strengths from the start. In contrast, in the concrete with fly ash, the strength only increased after the 28th day of setting.

The amount of nanosilica used was minimal compared to that of fly ash. This brings us to the question whether stronger concretes can be produced with a higher amount of nanosilica.

The results found so far indicate that there is an improvement when using nanomaterials in the concrete mix. These findings agree with those reported in previous studies. It has been documented that compressive strength increases significantly with the addition of nanosilica due to the pozzolanic reaction, as it quickly produces a C-S-H gel. This reduces the porosity of structures, given the nanometric size of nanosilica particles 35.

This also provides benefits such as pollution reduction, lower construction costs due to lower material requirements, high strength, good workability, high impermeability, and no need for using superplating agents 36. It must be acknowledged that, due to the limitations of human and material resources to carry out this research, the studied sample is limited. The results show that the addition of these aggregates to concrete improves their performance. More research is necessary to confirm our results.

Conclusions

This study analyzed the benefits of incorporating nanosilica and fly ash into hydraulic concrete mixtures, concluding that the compressive strength substantially improves with nanosilica.

Based on the results obtained, the material that yielded the best results was concrete with nanosilica. This aggregate had a greater impact on improving the properties of concrete. It should be noted that the results of this research will be the input for a new project.

The purpose of this research was to verify whether common concrete elaborated with CPC shows improved properties when adding nanosilica and fly ash.

Considering the above, it is concluded that the key to improving concrete through nanosilica and fly ash is the composition of the mixture. It is key to reduce the amount of cement paste (i.e., cement base) so that the new aggregate occupies the free space. With the voids filled, there is no more poor, porous concrete. In the same way, the mechanical properties of the binder, which is the cement paste, could be improved.

Finally, it can be stated that concrete technology is an area that has drawn the attention of the academic and professional community. As it is a centennial material, any improvements that contribute to improving the performance of concrete are always welcome. Thus, this research is an attempt to improve the compressive strength of this important material, which has a prominent future in the construction industry.

References

License

Copyright (c) 2023 Sara Cristina Solache de la Torre, David Joaquín Delgado-Hernández, Juan Carlos Arteaga-Arcos

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

From the edition of the V23N3 of year 2018 forward, the Creative Commons License "Attribution-Non-Commercial - No Derivative Works " is changed to the following:

Attribution - Non-Commercial - Share the same: this license allows others to distribute, remix, retouch, and create from your work in a non-commercial way, as long as they give you credit and license their new creations under the same conditions.

2.jpg)