DOI:

https://doi.org/10.14483/23448393.22528Published:

2025-04-15Issue:

Vol. 30 No. 1 (2025): January-AprilSection:

Civil and Environmental EngineeringAnalysis of the Physical and Mechanical Behavior of Soil Reinforced with Banana Fibers

Análisis del comportamiento físico y mecánico del suelo reforzado con fibras de plátano

Keywords:

Soils, natural fibers, banana fibers, geotechnical properties, physical and mechanical behavior (en).Keywords:

Suelos, fibras naturales, fibras de plátano, propiedades geotécnicas (es).Downloads

References

S. Hasnah et al., "A review on natural fiber reinforced polymer composites (NFRPC) for sustainable industrial applications," Polymers, vol. 14, no. 17, art. 3698, 2022. https://doi.org/10.3390/polym14173698

N. Faizah, M. AlHamidi, F. Mansor, and S. Anuar, "Influence of banana fiber on shear strength of clay soil," IOP Conf. Ser. Mater. Sci. Eng., vol. 864, no. 1, art. 012099, 2020. https://doi.org/10.1088/1757-899X/864/1/012099

R. Kiani et al., "Sustainability in construction projects: A systematic literature review," Sustainability, vol. 13, no. 4, art. 1932, 2021. https://doi.org/10.3390/su13041932

G. Alhakim, L. Jaber, O. Baalbaki, and F. Barraj, "Utilization of fan palm, date palm, and phragmites australis fibers for improving the mechanical behavior of sandy soil," Geomech. Energy Environ., vol. 33, art. 100427, 2023. https://doi.org/10.1016/j.gete.2022.100427

A. Temitayo, O. Olugbemiga, O. Olufemi, and E. Temidayo, "Physico-chemical, thermal and micro-structural characterization of four common banana pseudo-stem fiber cultivars in Nigeria," J. Nat. Fibers, vol. 20, no. 1, art. 2167031, 2023a. https://doi.org/10.1080/15440478.2023.2167031

W. Qamar, A. Hassan, Z. Rehman, and Z. Masoud, "Sustainable application of wool-banana bio-composite waste material in geotechnical engineering for enhancement of elastoplastic strain and resilience of subgrade expansive clays," Sustain., vol. 14, no. 20, art. 13215, 2022. https://doi.org/10.3390/su142013215

A. Samir, F. Ashour, A. Abdel, and M. Bassyouni, "Recent advances in biodegradable polymers for sustainable applications," npj Mater. Degrad., vol. 6, art. 68, 2022. https://doi.org/10.1038/s41529-022-00277-7

S. Fogue et al., "Investigation of chemical, physical and morpho-mechanical properties of banana-plantain stalk fibers for ropes and woven fabrics used in composite and limited-lifespan geotextile," Heliyon, vol. 3, no. 8, art. e29656, 2024. https://doi.org/10.1016/j.heliyon.2024.e29656

V. Kumar et al., "Potential of banana based cellulose materials for advanced applications: A review on properties and technical challenges," Carbohydr. Polym. Technol. Appl., vol. 6, art. 100366, 2023. https://doi.org/10.1016/j.carpta.2023.100366

P. Badanayak, J. Seiko, and G. Bose, "Banana pseudostem fiber: A critical review on fiber extraction, characterization, and surface modification," J. Nat. Fibers., vol. 20, no. 1, art. 2168821, 2023. https://doi.org/10.1080/15440478.2023.2168821

J. C. León Carrasco, "Producción de banano de Perú alcanzó las 2.414.382 toneladas en 2023," Agraria.pe, 2024. [Online]. Available: https://agraria.pe/noticias/produccion-de-banano-de-peru-alcanzo-las-2-414-382-toneladas-37112#:~:text=Producci%C3%B3n%20de%20banano%20de%20Per%C3%BA%20alcanz%C3%B3%20las%202.414.382%20toneladas%20en%202023,-Enviar%20Imprimir&text=La%20principal%20regi%C3%B3n%20productora%20de,y%20Hu%C3%A1nuco%20con%20233.775%20toneladas

Minagri, "MINAGRI desarrollará tecnología que proteja al banano orgánico de letal hongo Fusarium Oxysporium," inia, 2020. [Online]. Available: https://www.inia.gob.pe/2020-nota-040/

D. Dutta and N. Sit, "Preparation and characterization of potato starch-based composite films reinforced by modified banana fibers and its application in packaging of grapes," Int. J. Biol. Macromol., vol. 254, part 2, art. 127791, 2024. https://doi.org/10.1016/j.ijbiomac.2023.127791

A. Temitayo, O. Olugbemiga, O. Olufemi, E. Temidayo, and M. Hussain, "Banana pseudo stem fiber, hybrid composites and applications: A review," Hybrid Adv., vol. 4, art. 100101, 2023b. https://doi.org/10.1016/j.hybadv.2023.100101

A. Karimah et al., "A review on natural fibers for development of eco-friendly bio-composite: Characteristics, and utilizations.," J. Mater. Res. Technol., vol. 13, pp. 2442-2458, 2021. https://doi.org/10.1016/j.jmrt.2021.06.014

A. Vinod, S. Suchart, and P. Jyotishkumar, "Renewable and sustainable biobased materials: an assessment on biofibers, biofilms, biopolymers and biocomposites," J. Clean. Prod., vol. 258, art. 120978, 2020. https://doi.org/10.1016/j.jclepro.2020.120978

S. Rangappa, S. Siengchin, and H. Dhakal, "Green-composites: Ecofriendly and Sustainability," Appl. Sci. Eng. Prog., vol. 13, no. 3, art. 183-184, 2020. https://doi.org/10.14416/j.asep.2020.06.001

T. Nguyen and B. Indraratna, "Natural fibre for geotechnical applications: Concepts, achievements and challenges," Sustain., vol. 15, no. 11, art. 8603, 2023. https://doi.org/10.3390/su15118603

P. Ellappan, V. Arumugam, and N. Muthukumaran, "Influence of natural fibres in strengthening of black cotton soil," IOP Conf. Ser. Mater. Sci. Eng., vol. 955, art. 012066, 2020. https://doi.org/10.1088/1757-899X/955/1/012066

D. Lal, R. Pravalika, S. Kumar, and G. Rao, "Stabilization of expansive soil by using Jute fiber," 3rd Int. Congr. Adv. Mech. Sci., vol. 998, art. 012045, 2020. https://doi.org/10.1088/1757-899X/998/1/012045

S. Prasanna and N. Macedon, "Application of jute fiber in soil stabilization," Sustain. Agri. Food Environ. Res., vol. 11, no. X, pp. 1-7, 2023. https://doi.org/10.20944/preprints202008.0534.v1

N. Bawadi, N. Ahmad, A. Mansor, S. Anuar, and M. Rahim, "Effect of natural fibers on the soil compaction characteristics," IOP Conf. Ser. Earth Environ. Sci., vol. 476, art. 012043, 2020. https://doi.org/10.1088/1755-1315/476/1/012043

L. Patil and S. Pusadkar, "MDD & OMC of black cotton soil reinforced with randomly distributed banana fibers," IOP Conf. Ser. Mater. Sci. Eng., vol. 970, art. 012029, 2020. https://doi.org/10.1088/1757-899X/970/1/012029

P. Somnath and S. Dipankar, "Performance evaluation of natural fiber reinforced Laterite soil for road pavement construction," Mater. Today Proc., vol. 62, part 2, art. 1246-1251, 2022. https://doi.org/10.1016/j.matpr.2022.04.534

S. Sridhar, H. Guruprasad, D. Naveenkumar, and D. Sangeetha, "Influence of treated coir fiber on durability properties of black cotton soil," Mater. Today Proc., vol. 80, part. 2, pp. 1611-1616, 2023. https://doi.org/10.1016/j.matpr.2023.02.127

S. Kumar, A. Kumar, and S. Naval, "Influence of Jute fibre on CBR value of expansive soil," Civil Eng. J., vol. 6, no. 6, pp. 1180-1194, 2020. https://doi.org/10.28991/cej-2020-03091539

M. Faisal, M. Khan, and K. Ali, "Effect of artificial and natural fibers on behavior of soil," Mater. Today Proc., vol. 64, part 1, pp. 481-487, 2022. https://doi.org/10.1016/j.matpr.2022.04.954

M. Wasim, J. Israr, K. Farooq, and H. Mujtaba, "Strength mechanism of a swelling soil improved with Jute fibers: A laboratory treatment," Geotech. Geol. Eng., vol. 41, no. 7, pp. 1-14, 2023. https://doi.org/10.1007/s10706-023-02517-2

Standard test method for particle-size analysis of soils, ASTM D422-63, ASTM International, 2022.

Standard practice for classification of soils for engineering purposes (unified soil classification system), ASTM D2487-17, ASTM International, 2020.

Standard test methods for liquid limit, plastic limit, and plasticity index of soils, ASTM D4318, ASTM International, 2010.

Standard test methods for laboratory compaction characteristics of soil using modified effort (56,000 ft-lbf/ft3 (2,700 kN-m/m3)), ASTM D1557-12, ASTM International, 2021.

Método de prueba estándar para la relación de carga de California (CBR) de suelos compactados en laboratorio, ASTM D1883-14, ASTM International, 2022.

Standard test method for unconfined compressive strength of cohesive soil, ASTM D2166-06, ASTM International, 2010.

C. Contreras, J. Albuja-Sánchez, O. Proaño, C. Ávila, and A. Damián-Chalán, "The influence of abaca fiber treated with sodium hydroxide on the deformation coefficients Cc, Cs, and Cv of Organic Soils," Fibers, vol. 12, no. 10, art. 89, 2024. https://doi.org/10.3390/fib12100089

S. Ramírez, "Influencia de la concentraión de NaOH en la resistencia mecánica a la tensión de un material compuesto reforzado con fibra de bambú," Doctoral Thesis, Universidad ECCI, Bogotá, Colombia, 2017. [Online]. Available: https://repositorio.ecci.edu.co/entities/publication/fbcd1dba-7d84-44ce-89c3-fee611d744a7

Vivek, R. K . Dutta, and R. Parti, "Effect of chemical treatment on the tensile strength behavior of coir geotextiles," J. Nat. Fibers., vol. 17, no. 4, pp. 542-556, 2020. https://doi.org/10.1080/15440478.2018.1503132

J. Nisar, M. Mir, and Vivek, "Study on optimal preparation and rheological characteristics of waste low density polyethylene (LDPE)/styrene butadiene styrene (SBS) composite modified asphalt binder," Constr. Build. Mater., vol. 407, art. 133459, 2023. https://doi.org/10.1016/j.conbuildmat.2023.133459

Vivek, R. K. Dutta, and R. Parti, "Application potential of treated coir geotextiles in unpaved roads," J. Nat. Fibers., vol. 17, no. 10, pp. 1454-1467, 2020. https://doi.org/10.1080/15440478.2019.1578718

Vivek, R. Dutta, and R. Parti, "Effect of chemical treatment of the coir geotextiles on the interface properties of sand–/clay–coir geotextile interface," J J. Inst. Eng. (India) Series A, vol. 100, pp. 357-365, 2019. https://doi.org/10.1007/s40030-018-0348-x

Vivek and R. Dutta, "Bearing ratio behavior of sand overlying clay with treated coir geotextiles at the interface," J. Nat. Fibers., vol. 19, no. 14, pp. 7534-7541, 2021. https://doi.org/10.1080/15440478.2021.1952135

P. Jaswall, Vivek and S. Sinha, "Investigation on tensile strength characterisation of untreated and surface treated coir geotextiles," J. Ind. Text., vol. 52, 2022. https://doi.org/10.1177/15280837221118847

P. Jaswal and Vivek, "Experimental study on monotonic behaviour of two-layered unpaved road model reinforced with treated coir geotextiles," Int. J. Pavement Res. Technol., vol. 17, pp. 1377-1388, 2023. https://doi.org/10.1007/s42947-023-00293-z

P. Jaswal, Vivek, and S. Sinha, "Improvement in the performance of two layered model pavement with treated coir geotextile at the interface," J. Ind. Text., vol. 52, 2022. https://doi.org/10.1177/15280837221114161

Standard guide for x-ray emission spectrometric analysis, ASTM E1621-94(1999), ASTM International, 2017.

Standard test method for density of hydraulic, ASTM C188, ASTM International, 2017.

Standard test method for tensile properties of single textile fibers, ASTM D3822, ASTM International, 2020.

V. Sagar and T. Kaki, "Effects of coir fibre on the strength of black cotton soil," Int. J. Eng. Res. Mech. Civil Eng. (IJERMCE), vol. 10, no. 6, pp. 7-10, 2023. https://doi.org/10.1016/j.matpr.2023.02.127

J. García Chumacero, P. Acevedo Torres, C. Corcuera La Portilla, and S. Muñoz Pérez, "Influence of artificial intelligence on the optimization of the dosage of natural hydraulic lime, plastic and metallic fibers on the geological characteristics of a treated soil," Rev. Ing. Construcc., vol. 38, no. 3, pp. 473-484, 2023. https://doi.org/10.7764/RIC.00080.21

C. J. M. García, P. L. Acevedo Torres, C. C. Corcuera la Portilla, S. P. Muñoz Pérez, and L. I. Villena Zapata, "Effect of the reuse of plastic and metallic fibers on the characteristics of a gravelly soil with clays stabilized with natural hydraulic lime," Innov. Infrastruct. Solut., vol. 8, art. 185, 2023. https://doi.org/10.1007/s41062-023-01155-0

J. M. García Chumacero, J. L. Gonzales Macedo, and D. J. Sánchez Castillo, "Contribution of agricultural ashes and HDPE as a waste material for a sustainable environment applied to the stabilization of a low plasticity clay soil," Innov. Infrastruct. Solut., vol. 9, art. 67, 2024. https://doi.org/10.1007/s41062-024-01372-1

J. García, G. Arriola, L. Villena, and S. Muñoz, "Strength of concrete using partial addition of residual wood ash with respect to cement," Rev. Politéc., vol. 52, no. 1, pp. 45-54, 2023. https://doi.org/10.33333/rp.vol52n1.05

S. Muñoz, L. Villena, F. Tesen, Y. Coronel, J. García, and C. Brast, "Influence of coconut fiber on mortar properties in masonry walls," Electron. J. Struct. Eng., vol. 23, no. 4, pp. 52-58, 2023. https://doi.org/10.56748/ejse.23391

J. Bereche and J. García, "Replacement of fine aggregate with refractory brick residue in concrete exposed to elevated temperatures," Rev. Politéc., vol. 53, no. 2, pp. 79-88, 2024. https://doi.org/https://doi.org/10.33333/rp.vol53n2.08

C. J. Burgos, B. E. Cubas, and C. J. García, "Analysis of the combination of glass and polypropylene fibers on the mechanical properties of mortar," J. Build. Pathol. Rehabil., vol. 10, art. 22, 2024. https://doi.org/10.1007/s41024-024-00532-1

J. Chaname, J. García, and G. Arriola, "Mejoramiento de las propiedades mecánicas del concreto estructural utilizando microporoso etileno acetato de vinilo," Rev. Politéc., vol. 53, no. 2, pp. 17-26, 2024. https://doi.org/10.33333/rp.vol53n2.02

G. Cabanillas Hernández, J. García Chumacero, L. Villegas Granados, G. Arriola Carrasco, and N. Marín Bardales, "Sustainable use of wood sawdust as a replacement for fine aggregate to improve the properties of concrete: A Peruvian case study," Innov. Infrastruct. Solut., vol. 9, no. 7, art. 233, 2024. https://doi.org/10.1007/s41062-024-01567-6

A. L. Y. Cadenas, H. R. M. Jacinto, C. J. M. García, V. N. R. Salinas, and C. C. O. Chávez, "Experimental study of hybrid concrete blocks based on sawdust and calcined clay using cement as a binder," Innov. Infrastruct. Solut., vol. 9, art. 445, 2024. https://doi.org/10.1007/s41062-024-01768-z

How to Cite

APA

ACM

ACS

ABNT

Chicago

Harvard

IEEE

MLA

Turabian

Vancouver

Download Citation

Recibido: 26 de julio de 2024; Revisión recibida: 25 de noviembre de 2024; Aceptado: 1 de marzo de 2025

Abstract

Context:

Soils reinforced with natural fibers such as banana fibers (BF) constitute a promising alternative for improving the geotechnical properties of the soil, especially in rapidly growing urban contexts like Peru.

Methods:

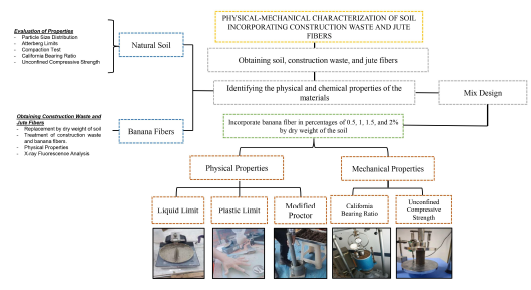

This study was structured into four stages: the extraction and preparation of soil samples; the evaluation of the physical characteristics of the fibers; mixing with proportions of 0.5,1,1.5, and 2% BF relative to the soil dry weight; and physical and mechanical tests to assess the effects on geotechnical properties.

Results:

The addition of 1% BF optimized the properties of the modified soil: the maximum dry density remained stable, the California bearing ratio increased by 5.95%, and the unconfined compressive strength increased by 23.81% compared to natural soil.

Conclusions:

The use of BF-treated soil meets the local standards for application in infrastructure such as roads and pavements, thus promoting sustainable construction practices and contributing to the development of resilient and environmentally responsible infrastructure.

Keywords:

soils, natural fibers, banana fibers, geotechnical properties, physical and mechanical behavior.Resumen

Contexto:

Los suelos reforzados con fibras naturales como las fibras de plátano (FP) representan una alternativa prometedora para mejorar las propiedades geotécnicas de los suelos arcillosos de baja plasticidad, especialmente en contextos urbanos de rápido crecimiento como el Perú.

Métodos:

Este estudio se estructuró en cuatro etapas: la extracción y preparación de muestras del suelo; la evaluación de las características de la fibra; la mezcla con proporciones de 0.5, 1, 1.5 y 2% de FP respecto al peso seco del suelo; y la realización de pruebas físicas y mecánicas del suelo estabilizado.

Resultados:

La adición de 1 % de FP optimizó las propiedades del suelo natural, pues la máxima densidad seca se mantuvo estable, el índice de soporte de California aumentó en un 5.95% y la resistencia a la compresión no confinada incrementó en un 23.81 % en comparación con el suelo natural.

Conclusiones:

El uso del suelo tratado con FP cumple con los estándares locales para aplicaciones en infraestructuras como carreteras y pavimentaciones, lo que promueve prácticas constructivas sostenibles y contribuye al desarrollo de infraestructuras resilientes y ambientalmente responsables.

Palabras clave:

suelos, fibras naturales, fibras de plátano, propiedades geotécnicas, comportamiento físico y mecánico.1. Introduction

Soil stabilization remains a critical focus in construction and environmental engineering, with natural fibers (NF) emerging as a sustainable and cost-effective reinforcement technique. 1 highlight their advantages: low cost, environmental benefits, and high availability, which makes them a viable alternative to conventional materials 2,3 emphasize their importance in reducing the environmental impacts of construction projects. Low soil tensile strength often leads to structural failures 4, but fibers improve stability by leveraging their tensile properties, reducing cracks and degradation 5,6. This reinforcement occurs through interlocking and friction, thereby enhancing resistance 7. Natural fibers are subject to degradation processes such as biodegradation, moisture exposure, and temperature fluctuations, which can affect their structural integrity and, consequently, the stability of the reinforced soil. It is essential to investigate how these factors influence the longevity of the fibers to ensure that the observed geotechnical improvements remain effective over time.

Global banana production is estimated at nearly 30.5 million tons per year, making it the third most important export product after fuel and wood 8. Furthermore, it is expected to increase at an annual rate of 1.5%, reaching 135 million tons by 2028 9. India leads global production, accounting for approximately 31.5 % of the total, followed by mainland China, Indonesia, Brazil, and Ecuador 10. In 2023, Peru's commercial banana (plantain) production reached 2 414 382 tons 11. The country has 160 000 hectares dedicated to banana and plantain cultivation, with more than 70 % concentrated in the Amazon region 12. Banana fibers contain approximately 40% cellulose, 21.5% hemicellulose, 24% lignin, 0.34 % pectin, 7.2 % extractable lipophilic sugars, and 7.36 % water-soluble sugars 8.

The use of randomly distributed natural fibers to reinforce soil is an effective and simple method, similar to cement or lime stabilization 13. For example, banana fibers, with densities of 1.2-1.6 g/cm3, an elongation of 5.3%, and a tensile strength between 355 and 754 MPa, are biodegradable 14,15. While synthetic fibers offer superior performance, natural fibers are more cost-effective, accessible, and environmentally friendly, making them a valuable option for sustainable projects 16,17. Currently, chemical pretreatments such as sodium hydroxide, calcium hydroxide, hydrogen peroxide, sulfuric acid, silane, enzymes, epoxy resins, and calcium sulfate dihydrate are used to enhance these organic fibers, increasing their durability over time.

Banana fibers (BFs) are preferred for their high tensile strength (355-754 MPa), biodegradability, availability in tropical regions like Peru, and low cost. They are more affordable than jute or coir since they are agricultural byproducts. Additionally, their use helps to reduce agricultural waste and mitigate environmental impacts, contributing to sustainable and eco-friendly projects.

The use of fibers in soils offers multiple benefits and is suitable for various geotechnical applications, including subbase layers, foundations, slope protection, and earthquake- resistant structures 18. Many studies have demonstrated the influence of incorporating BF into the soil. For example, 19 observed that a proportion of 0.4 % BF increased the liquid limit by 25 %, and the plastic limit substantially increased by 125.45 % compared to natural soil. 20 found that 2 % BF increased both the liquid and plastic limits by 21 %. However, further research is needed on the physical behavior of soil with different proportions of BF by dry weight of soil 2.

The addition of natural fibers (NFs) significantly influences soil properties, particularly the maximum dry density (MDD), the California bearing ratio (CBR), and the unconfined compressive strength (UCS). Studies have shown mixed effects on MDD: while 0.5 % fiber increased MDD by 1.58 and 6.67% 21,22, higher proportions such as 2 % led to reductions of 7.78 and 2.01 % 19,23. This decline was attributed to excess voids acting as physical barriers at higher fiber contents 24. Meanwhile, the addition of 0.4 % BF increased the optimum moisture content (OMC) by up to 20 % compared to natural soil 19. Similarly, 21 demonstrated that adding 0.5% BF stabilized the soil, achieving an OMC of 16% relative to natural soil. Additionally, 22 found that, at the same fiber proportions, the OMC increased by 41.03 % compared to natural soil. Small additions of fiber, i.e., 0.3 and 0.4 %, increased the CBR by 23.71 and 21.55%, respectively 19,24. Larger proportions like 1 and 1.25% achieved more substantial improvements, enhancing the CBR by up to 226.92 % 25,26. This enhancement is due to the improved soil cohesion and stress redistribution provided by fibers. Similarly, the UCS results showed significant strength gains, with 0.3 and 1.5 % fiber increasing the reported values by 26.41 and 100%, respectively 24,27. These improvements result from enhanced internal cohesion and shear strength, as fibers reinforce the soil structure, boosting its load-bearing capacity under compression 28.

This study addresses a significant knowledge gap, as no prior research in Peru has explored the incorporation of BF to improve soil behavior, despite the existence of international studies. The objective is to analyze the physical and mechanical behavior of soil reinforced with BF while focusing on four percentages, i.e., 0.50, 1, 1.5, and 2% of soil dry weight, in order to evaluate their effect. A key novelty of this research lies in using natural waste materials like BF, promoting sustainability by reducing the environmental impact of improper waste disposal. This aligns with Sustainable Development Goal (SDG) 12 (responsible consumption and production) by encouraging resource-efficient practices and with SDG 9 (industry, innovation, and infrastructure) by fostering green industries and innovation.

However, the limitations of this work include the focus on laboratory-scale tests without considering field conditions, as well as the results being specific to the chemical composition and properties of the BF used. Further research is needed to validate the findings regarding diverse soil types and environmental conditions. This research provides a foundation for integrating BF as a sustainable material in geotechnical applications, offering insights into its potential to enhance soil properties and contribute to more environmentally responsible construction practices.

2. Materials and methods

2.1. Materials Soil

The soil samples used in this study were collected from Pueblo Joven Las Dunas, in the city of Lambayeque, Peru. Once the location had been identified, soil samples were excavated from a depth of 1.50 m and placed in airtight bags. Approximately 250 kg of soil were extracted from these pits.

The selected road is strategically important for the movement of agricultural products and connections between surrounding communities. The main geotechnical characteristics of its soil are presented in Table I.

Table I: Geotechnical properties of the natural soil studied

Test

Characteristics

Standard

Results

Depth of sample taken (m)

0.5-1.5

-

Grain size distribution

Gravel >4.75 mm ( %)

ASTM D422 29

-

Sand 0.075 - 4.75 mm ( %)

20.82

Fines <0.075 mm ( %)

79.18

Soil type

Classification (USCS)

ASTM D2487 30

CL

Atterberg limits

Liquid limit ( %)

ASTM D4318 31

20.3

Plastic limit ( %)

19.2

Modified Proctor tests

Maximum dry density (g/cm3)

ASTM D1557 32

1.8

Optimum moisture content ( %)

12.7

Strength test

California bearing ratio at 95 % MDD ( %)

ASTM D1883 33

33.6

California bearing ratio at 100 % MDD ( %)

34.4

Unconfined compressive strength after 28 days (MPa)

ASTM D2166 34

0.21

2.1.1. Banana fiber

Locally available BF (Fig. 1) was used at various stages, and proper treatment was conducted before incorporating it into the soil mix. The fibers were treated with a 5 % sodium hydroxide (NaOH) solution for 24 hours and then air-dried 35. This sodium hydroxide treatment increased the tensile strength of the natural fibers 36-44. In the application process, the soil was prepared, and BF was mixed in proportions of 0.50,1, 1.5, and 2 % by dry weight of soil, using suitable mixing equipment to ensure a homogeneous distribution.

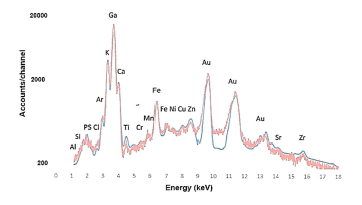

Various physical properties of the BF are described in Table II. Additionally, based on an analysis using X-ray fluorescence testing as per ASTM E1621-16 45, the chemical components identified in the fibers are shown in Table III and Fig. 2.

2.2. Methods

2.2.1. Liquid limit, plastic limit, and modified Proctor test

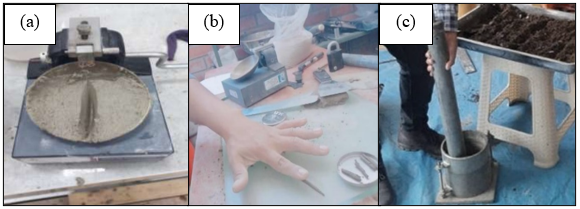

The liquid and plastic limits (LL and PL) were determined according to ASTM D4318 31. The modified Proctor test for both natural and modified soil was conducted in accordance with ASTM D1557 32. Fig. 3 depicts the physical tests conducted on the soil.

Figure 1: Banana fiber

Table III: Chemical properties of the banana fibers used

Element

% mass

Al2O3

0.338

SiO2

1.644

P2O5

14.595

SO2

7.806

ClO2

4.973

K2O

66.567

CaO

4.764

TiO2

5.028

MnO

11.019

Figure 2: X-ray fluorescence analysis of the banana fibers used

Figure 3: a) Liquid limit, b) plastic limit, and c) modified Proctor tests

2.2.2. California bearing ratio and unconfined compressive strength

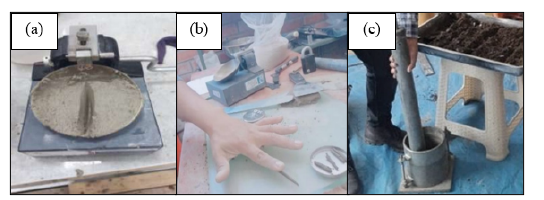

Fig. 4 shows the mechanical tests performed on the soil containing BF. The CBR was evaluated according to ASTM D1883 33, and the UCS was evaluated according to ASTM D2166 34.

2.2.3. Experimental program

The methodology developed for this research was divided into four stages. Fig. 5 illustrates its process flow.

Figure 4: a) California bearing ratio and b) unconfined compressive strength testing

Figure 5: Research process

Phase I involved soil sampling and processing, with samples extracted from a depth of 1.50 m in the Lambayeque region of Peru, totaling approximately 250 kg. This material was divided for physical and mechanical tests in its natural state, which included grain size analysis, Atterberg limits, specific gravity, compaction, CBR, and UCS. Soil stabilization in this study was both mechanical and chemical. This combination was chosen due to its synergistic benefits, as mechanical stabilization with fibers enhances soil cohesion and internal strength, while chemical treatment optimizes the interaction between the fibers and the soil, improving the structure and load-bearing capacity of the material.

Phase II evaluated the physical characteristics of the BF, which were first cleaned and then treated with a 5 % NaOH solution for 24 hours to enhance their mechanical and bonding properties. After treatment, the fibers were thoroughly rinsed with water, air-dried, and cut into lengths of approximately 40-50 mm for uniformity.

Phase III involved the preparation of soil-BF mixtures, where the fibers were randomly distributed into the dry sample in proportions of 0.50, 1.0, 1.5, and 2.0% by weight of dry soil. Care was taken to ensure even mixing for homogeneity. The treated organic fiber was randomly placed in the natural soil due to its ease of application during the stabilization process.

Finally, phase IV focused on conducting physical and mechanical tests on the experimental soil-fiber mixtures to assess their suitability for light traffic subbase applications. Table IV presents the composition of these mixtures.

Table IV: Description of each mixture

Nomenclature

Description

D-0

Natural soil

D-05BF

Natural soil + 0.5 % BF

D-10BF

Natural soil + 1.0% BF

D-15BF

Natural soil + 1.5% BF

D-20BF

Natural soil + 2.0 % BF

3. Results and discussion

3.1. Physical properties

3.1.1. Liquid and plastic limits

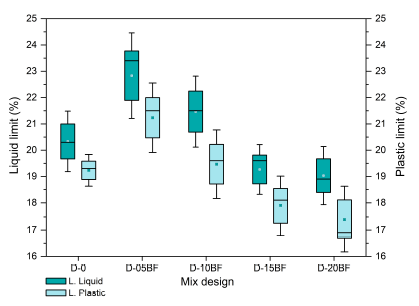

According to Fig. 6, and based on ASTM D4318 31, the natural soil exhibited a LL of 20.3% and a PL of 19.2%. An analysis of the sample with 0.5% BF revealed an increase of 12.32% in the LL and 10.42 % in the PL compared to natural soil. With 1 % BF, the LL increased by 5.91 %, and the PL showed a slight increase (1.56 %) compared to the 0.5 % BF sample. The samples with 1.5 and 2 % BF showed LL reductions of 4.93 and 6.77%, respectively, in comparison with natural soil, while the PL decreased by 6.40 and 9.38 %. These results suggest a reduction in plasticity, especially with the addition of 1.5 and 2 % BF.

Fig. 6 also suggests that the addition of low BF concentrations increases the LL and PL in soil samples, which can be attributed to the presence of K2O and P2O5, which allow enhancing soil cohesion and water retention capacity. However, at higher concentrations (1.5 and 2%), the reduction in the LL and PL indicate that an excess of these components may negatively affect plasticity.

These findings are similar to those of 19, who demonstrated that 0.4 % BF increased the LL by 25 %. Likewise, the PL substantially increased by 125.45% compared to natural soil. However, 20 observed that 2 % fiber increased both the LL and PL by 21 %, which contrasts with our research findings. These discrepancies may be due to differences in the specific properties of the fibers used, the nature of the base soil, and the methodologies applied in the experiments.

Figure 6: Variation in consistency limits for different banana fiber proportions

3.1.2. Modified Proctor test

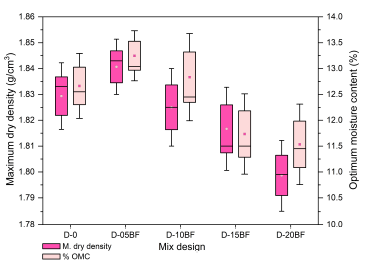

According to the compaction test (Fig. 7), which was conducted according to ASTM D1557 32, the studied natural soil has a MDD of 1.83 % and an OMC of 12.7%. When adding 0.5 % BF, the MDD increases by 0.55 % and the OMC by 3.94 % compared to natural soil. Similarly, with 1 % BF, the MDD remains stable, but the OMC increases slightly (0.79). With 1.5% BF, the MDD decreases by 0.55% and the OMC by 7.87%. Finally, with 2% BF, the MDD decreases by 1.64% and the OMC by 9.45% compared to natural soil. These results indicate that the addition of BF has a variable effect on MDD and OMC, with increases at low BF doses and decreases at higher doses (Fig. 7). This could be related to the presence of Al2O3 (0.338%) and SiO2 (1.644%) in the fibers, which may interfere with the uniform compaction of the soil by forming agglomerations, thereby reducing its density and water absorption capacity.

19 found that the soil's MDD increased by 7.78 % with 2 % BF. In addition, the OMC decreased by 20 % with the addition of 0.4 % BF compared to natural soil. Similarly, 21 showed that the incorporation of 0.5 % NF improved the MDD by 1.58 %, while the OMC remained stable at 16 % in comparison with untreated soil. However, other studies reported that 2 and 3 % NF reduced the MDD and OMC by 2.01 and 55.84%, respectively 23,48. Higher concentrations of NF can introduce voids and destabilize the soil structure, decreasing its density and moisture retention capacity. The observed variations may be due to differences in the properties of the fibers, the nature of the soil, and the experimental methodologies used.

Figure 7: Variation in MDD and OMC when using different banana fiber proportions

3.2. Mechanical properties

3.2.1. California bearing ratio

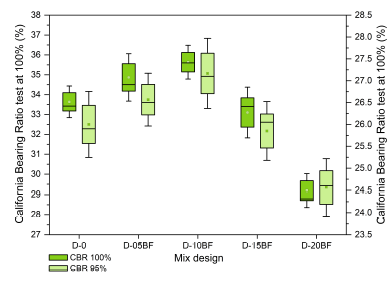

As shown in Fig. 8, the CBR value at 100 % for natural soil is 33.6 %. Adding 0.5 and 1 % BF increases this value by 3.87 and 5.95 %, respectively. However, increasing the BF content to 1.5 % slightly decreases the CBR by 1.49 %. Similarly, with 2 % BF, the CBR decreases significantly (13.10 %) when compared to untreated soil. These results indicate that the addition of BF enhances the bearing capacity of the soil, albeit up to a certain point, after which its effectiveness decreases.

The CBR value presented in Fig. 8 improves with up to 1 % BF, suggesting that MnO and CaO (4.764 %) contribute to an increased resistance to applied loads. However, the decrease in CBR at higher concentrations may indicate that an excessive proportion of these compounds reduces soil cohesion, thereby affecting stability.

These findings are similar to those of 24, who found that 0.3 % BF increased the CBR by 23.71 % compared to the natural sample. On the other hand, with 0.4 % BF, the CBR of the soil increased by 21.55 % 19. Additionally, 28 demonstrated that the incorporation of 1 % BF improved the soil support by 32.6 %. Other studies have shown increases of 68 and 171 % with the same fiber proportions compared to untreated soil 29,30. These results suggest that the addition of BF significantly improves the soil's bearing capacity by increasing its cohesion and internal strength, with more pronounced increases as the fiber proportion approaches optimal levels.

3.2.2. Unconfined compressive strength

As shown in Fig. 9, during UCS testing, optimal results were observed after 21 days with different doses of BF. The natural soil reported a UCS of 0.20 MPa, while adding 0.5 % BF increased this value by 14.29 %. With an addition of 1 % BF, the strength further increased by 23.81 %. However, increasing BF content to 1.5 % returned the strength to 0.20 MPa, equal to that of natural soil. Finally, with 2 % BF, the strength decreased significantly (14.29 %). These results indicate that BF addition enhances soil strength up to a certain point, beyond which its effectiveness diminishes. Fig. 9 shows that the UCS increases significantly with up to 1 % BF due to the improved load transfer facilitated by the presence of SO2 (7.806 %) and TiO2 (5.028 %), which enhance rigidity and durability. However, at higher concentrations, the UCS decreases, likely due to the heterogeneous distribution of the fibers, which affects the structural integrity of the soil.

Figure 8: Variation in CBR for different banana fiber proportions

The incorporation of BF into the soil improves its physical and chemical adhesion, optimizing stress transfer and increasing its load-bearing capacity. The NaOH treatment enhances adhesion and strength, while the fibers distribute stresses uniformly, reducing localized failures and improving ductility. An optimal proportion of 1 % BF significantly improves both the CBR and the UCS, although higher proportions may negatively impact soil compaction and strength.

By comparing these results against previous research, it is observed that low to moderate doses of BF (e.g., 0.5 and 1 %) significantly improve soil strength, which is consistent with the findings of 24, who found a 26.41 % increase in UCS with 0.3 % BF compared to natural soil. However, our results differ from those reported by 27, who observed a 100 % increase in strength with 1.5 % BF, contrasting with the strength stabilization observed in our study. Various studies have shown that organic materials significantly enhance soil properties 49-51, which makes them valuable for the civil construction industry 52-58. These discrepancies could be due to differences in the nature of the soil, the properties of the fibers used, and the experimental methodologies applied.

Figure 9: Variation in consistency limits for different banana fiber proportions

3.3. Statistical analysis

3.3.1. Consistency limit

An ANOVA analysis indicated significant LL differences between the mix designs (p=0.0089), unlike the PL ( p=0.2075). The Tukey test showed that D-05BF and D-10BF have significantly higher values than D-15BF and D-20BF. This suggests that a moderate amount of BF improves the material's cohesion, but excessive amounts reduce its plasticity.

3.3.2. Maximum dry density and optimum moisture content

Both of these parameters are significant according to the ANOVA (p=0.0207 and p=0.0248, respectively). The Tukey test indicated that the MDD increases with small amounts of fiber (D-05BF and D-10BF) and decreases with higher additions (D-15BF and D-20BF). Similarly, the moisture content is higher in D-05BF and D-10BF but decreases in D-15BF and D-20BF, suggesting that fiber initially enhances water retention before losing its effect.

3.3.3. CBR at 100 and 95 %

The ANOVA showed significant differences for the soil tested with CBR at 100 and 95 % (p=0.0011 and p=0.0006). The Tukey test confirmed that D-05BF and D-10BF have higher CBR values than D-0, while D-15BF and D-20BF show a notable decrease. This indicates that fiber enhances structural strength up to a certain point, but excessive amounts negatively affect material compaction.

3.3.4. Unconfined compressive strength

This parameter is highly significant (p=0.0001). The Tukey test indicated that D-10BF has the highest strength, while D-20BF has the lowest. This suggests that a moderate fiber addition reinforces soil cohesion, but an excess reduces the material's load-bearing capacity.

In conclusion, adding BF improves mechanical properties by up to 10 %, but higher amounts result in losses regarding cohesion and compaction.

4. Conclusions

The incorporation of BF has a significant influence on the physical properties of the soil. The conclusions drawn from the findings are presented below.

The chemical characteristics of the natural material (BF) can vary due to the diversity of its sources and the treatment it undergoes before being incorporated as reinforcement into the soil. These variations can affect the quality of the soil, with a direct impact on the geotechnical characteristics of the experimental sample.

This analysis highlights that the chemical properties of BF, particularly the high levels of K2O, P2O5, and MnO, play a crucial role in enhancing the geotechnical properties of the soil.

The optimal proportion of BF was 1.0 %, as it exhibited the most significant values in relation to the geotechnical properties of the soil. The MDD remained stable, the CBR increased by 5.95 %, and the UCS increased by 23.81 % compared to natural soil. These results emphasize that the inclusion of BF can strengthen the soil, making it more resistant and effective for construction applications, especially in rapidly growing urban areas like Peru. Additionally, the use of BF-treated soil meets the local standards for application in projects such as road construction and paving, thus ensuring proper regulatory compliance and contributing to the environmental sustainability of infrastructures. However, it is crucial to consider that higher doses of BF could have adverse effects on the mechanical behavior of the soil.

We suggest conducting additional microstructural tests to delve deeper into the specific interaction between BF and the soil, which will allow for a more thorough evaluation of the stability and durability of the modified material. These tests could reveal the way in which fibers influence the soil's microstructure, including the formation of particle bridges and fiber orientation under load. Evaluating how environmental conditions (e.g., moisture and temperature) affect fiber adhesion and long-term behavior is crucial to ensuring the material's sustainability in real-world applications.

Acknowledgements

5. Acknowledgements

We are grateful to the Professional School of Civil Engineering of Universidad Señor de Sipán for providing us with the facilities to carry out this research.

References

8. Author contributions

License

Copyright (c) 2025 Favio Osmar Schreiber Robles, Socrates Pedro Muñoz Pérez, Juan Martin Garcia Chumacero, Elver Sanchez Diaz, Carlos Arturo Damiani Lazo, Juan De Dios Malpartida Iturregui, Angel Antonio Ruiz Pico, Edwin Adolfo Diaz Ortiz, Ernesto Dante Rodríguez Lafitte, Ana Paula Bernal Izquierdo

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

From the edition of the V23N3 of year 2018 forward, the Creative Commons License "Attribution-Non-Commercial - No Derivative Works " is changed to the following:

Attribution - Non-Commercial - Share the same: this license allows others to distribute, remix, retouch, and create from your work in a non-commercial way, as long as they give you credit and license their new creations under the same conditions.

2.jpg)